BREEAM Thermal Imaging Surveys & APT Sound Testing

For over a decade, APT Sound Testing has been at the forefront of providing professional BREEAM thermal imaging surveys, specialising in checking for insulation continuity and identifying potential thermal anomalies in buildings. Our commitment to excellence is underscored by our use of the highest-resolution thermal imaging camera equipment available in the industry. All our surveyors are certified Level 2 thermographers, ensuring that every inspection meets the stringent standards required for accurate and reliable thermographic analysis.

Understanding BREEAM and the Importance of Thermographic Surveys

BREEAM (Building Research Establishment Environmental Assessment Method) is the world’s leading environmental assessment method and rating system for buildings. It sets the benchmark for best practices in sustainable building design, construction, and operation. BREEAM assessments are integral to promoting energy efficiency, reducing environmental impact, and ensuring the sustainability of building projects.

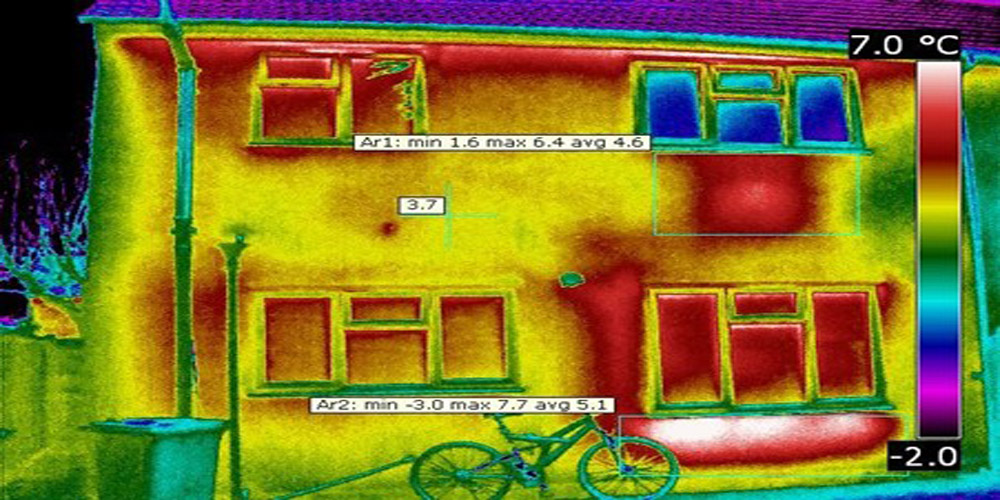

Thermographic surveys have become a critical component of BREEAM assessments. Both the BREEAM New Construction and BREEAM Domestic Refurbishment programs recognize the significant benefits of conducting thermographic surveys by awarding credits when a Level 2 certified thermographer performs a suitable thermal inspection. These surveys help in identifying areas of heat loss, insulation defects, and thermal bridging, which can affect a building’s energy performance and occupant comfort.

Our Range of Thermal Imaging Survey Services

At APT Sound Testing, we offer a comprehensive suite of thermal imaging surveys tailored to various sectors and requirements. Our services include:

- Data Centre Thermal Surveys: Data centres generate substantial heat due to the high density of electronic equipment. Our thermal surveys help identify hotspots, cooling inefficiencies, and potential equipment failures, ensuring optimal performance and preventing costly downtime.

- Building Envelope Thermal Surveys: We assess the exterior envelope of buildings to detect insulation gaps, air leakage paths, and thermal bridges. This is crucial for enhancing energy efficiency and meeting regulatory standards.

- Flat Roof Condition Thermal Surveys: Flat roofs are susceptible to water ingress and insulation defects. Our thermal imaging can detect trapped moisture and insulation failures without invasive procedures, aiding in proactive maintenance.

- Thermal Surveys on Electrical and Mechanical Installations: Overheating in electrical and mechanical systems can lead to failures or fire hazards. Our surveys identify overheating components, allowing for timely interventions.

Whether your project is commercial or domestic, and regardless of whether the inspection is for compliance with Part L2 (b) of the Building Regulations, insulation checks, air leakage paths, or underfloor heating inspections, we have the expertise to meet your specific needs. Our commitment to integrity ensures that you receive accurate and reliable results every time.

The Non-Invasive and Non-Destructive Nature of Our Surveys

One of the significant advantages of our BREEAM thermal surveys is that they are entirely non-invasive and non-destructive. This means that the building’s structure remains intact, with no mechanical or physical damage occurring during the inspection process. Thermal imaging technology allows us to “see” heat patterns on surfaces, revealing underlying issues without the need for physical intrusion.

Our Experienced and Certified Team

Our team comprises certified professional engineers who are not only highly skilled in thermal imaging techniques but also bring years of experience across various facets of construction, engineering, maintenance, and professional management. Their comprehensive understanding of BREEAM standards ensures that every survey is conducted in strict adherence to current regulations and best practices.

All our thermographers are Level 2 certified, a qualification that reflects advanced expertise in thermographic analysis. This certification is crucial for BREEAM assessments, as credits are awarded only when a Level 2 thermographer conducts the survey.

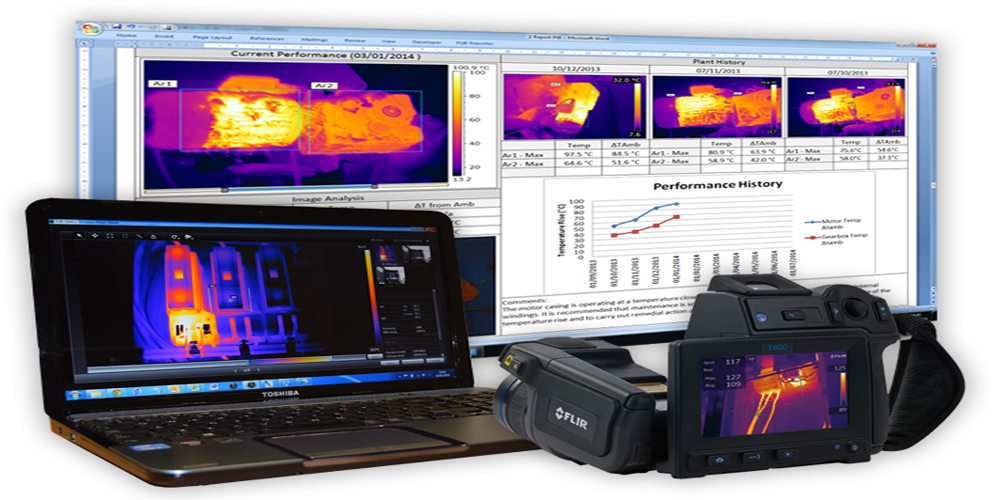

State-of-the-Art Thermal Imaging Equipment

To deliver the most accurate and detailed results, we utilize the best thermal imaging equipment available on the market. High-resolution cameras enable us to detect even the slightest temperature differentials, which might be missed by lower-grade equipment. This precision allows us to identify faults and inefficiencies that could impact a building’s energy performance and occupant comfort.

Efficient Reporting and Client Support

We understand that timely reporting is essential for project schedules and compliance requirements. That’s why we generate professional reports promptly, typically within 24 hours of completing the BREEAM survey. These reports are comprehensive yet easy to understand, providing clear insights into any identified issues along with recommendations for remediation.

Our commitment to proactive client service is a cornerstone of our business. We believe in building long-term relationships by consistently delivering high-quality services that exceed expectations. This client-centric approach is why many of our clients choose to work with us year after year.

Preparing for Your Thermal Imaging Survey

To ensure a smooth and efficient survey process, we require some preliminary information:

- Floor Plans and Elevation Drawings: These documents help our team plan the survey effectively, ensuring all critical areas are assessed.

- Building Location: Knowing the exact location allows us to consider local climate conditions that might affect the thermal imaging results.

Upon receiving these details, we provide a detailed quotation tailored to your project’s specific needs. Additionally, we supply an informative checklist to help you prepare for the thermal survey. This checklist includes guidelines on how to condition the building before the survey, such as heating requirements and occupancy considerations, to ensure optimal results.

Comprehensive Solutions Beyond Thermal Imaging

APT Sound Testing offers a holistic approach to building compliance and performance assessment. In addition to our thermal imaging surveys, we provide a range of pre-completion testing services, making us a one-stop solution for your project’s needs:

- Air Tightness Testing for Building Regulations Part L: Air leakage can significantly impact a building’s energy efficiency. Our air tightness tests help identify leaks and ensure compliance with Part L of the Building Regulations.

- Sound Testing for Building Regulations Part E: Acoustic performance is essential for occupant comfort. We conduct sound insulation testing to verify that buildings meet the required standards for airborne and impact noise transmission.

- Planning Noise Surveys for BS8233 & BS4142: We perform environmental noise assessments to inform planning applications and ensure compliance with British Standards BS8233 and BS4142.

- Server Room Integrity Testing: Maintaining the integrity of server rooms is crucial for data security and equipment longevity. Our tests ensure that these sensitive environments are adequately protected.

Why Choose APT Sound Testing?

- Expertise: With over 10 years of experience, we have a proven track record in delivering high-quality thermal imaging surveys and compliance testing.

- Certified Professionals: Our team of Level 2 certified thermographers and engineers brings unparalleled expertise to every project.

- Advanced Equipment: We invest in the latest thermal imaging technology to provide the most accurate and reliable results.

- Client-Centric Approach: We prioritize your needs, offering quick turnaround times, detailed reports, and ongoing support.

- Comprehensive Services: From thermal imaging to air tightness and sound testing, we offer a full suite of services to streamline your compliance processes.

Contact Us for Your Thermal Imaging Needs

If you’re in London or anywhere in the UK and require a thermal imaging survey, APT Sound Testing is ready to assist. Our professional and certified Level 2 thermographers will carry out your thermographic inspections in compliance with all necessary standards and current regulations.

To get started, simply provide us with:

- Floor Plans and Elevation Drawings: These help us understand the scope and layout of your project.

- Building Location: Knowing the site location allows us to schedule the survey at a time that suits you and consider any logistical factors.

Once we have these details, we’ll furnish you with a comprehensive quotation and our informative preparation checklist. This proactive approach ensures that the survey is conducted efficiently and yields the most accurate results.

Our Commitment to Sustainability and Excellence

At APT Sound Testing, we are passionate about what we do. We take great satisfaction in helping businesses and individuals make significant improvements in energy efficiency, sustainability, and compliance. By identifying thermal inefficiencies and providing actionable insights, we contribute to the creation of buildings that are not only compliant but also more comfortable and cost-effective to operate.

Our dedication to sustainability aligns with the core principles of BREEAM, and we are proud to support our clients in achieving their environmental performance goals. Whether it’s a new construction project aiming for the highest BREEAM rating or a refurbishment seeking to enhance its sustainability credentials, our thermal imaging surveys are an invaluable tool in the journey toward excellence.

Final Thoughts

Thermal imaging surveys are an essential component in modern building practices, offering insights that traditional inspection methods cannot. With the increasing emphasis on energy efficiency and sustainability, ensuring that your building meets the highest standards is more important than ever.

APT Sound Testing is committed to providing top-tier thermal imaging services that help you achieve compliance, improve performance, and contribute positively to the environment. Our expertise, advanced equipment, and client-focused approach make us the ideal partner for all your thermal imaging and compliance testing needs.

Get in Touch Today

Don’t leave your building’s thermal performance to chance. Contact APT Sound Testing today to schedule your BREEAM thermal imaging survey or to learn more about our comprehensive range of services. Let us help you ensure that your building not only meets regulatory requirements but also stands out as a model of sustainability and efficiency.

Contact Information:

We look forward to working with you and assisting in making your project a success.