APT: BREEAM Thermal Imaging Survey

Why you should use APT for your BREEAM Thermal Imaging Survey

There are many reasons why you should use APT for your thermal imaging survey for BREEAM. For a start our engineers are Level 3 thermographers for BREEAM (Building Research Establishment Environmental Assessment Method) thermal surveys, which mean they are highly recommended for several reasons:

- Advanced Training, Expertise and Certification: Level 3 thermographers have advanced training and certification, ensuring they possess the necessary skills to conduct thorough and accurate thermal inspections. They can troubleshoot, calibrate equipment, interpret data, and create detailed reports.

- Inspection Quality and Consistency: Highly qualified thermographers produce higher quality and more technically consistent inspections. They can develop inspection procedures, severity criteria, and interpret relevant codes.

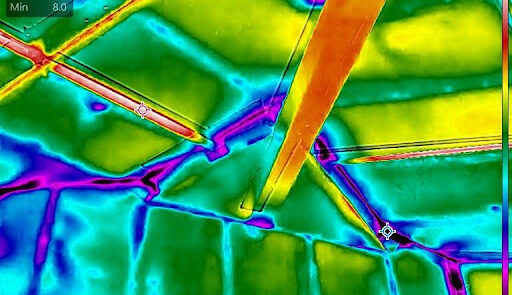

- Comprehensive Analysis of Building fabrics: Level 3 thermographers can provide quantitative data, utilising accurate temperature measurements to assess the severity of exceptions. They consider factors such as the load on the building envelope, equipment type, and changes in ambient conditions.

- Problem Identification on Building Envelopes: They can identify problems that may not present as obvious exceptions, ensuring a more comprehensive assessment of the thermal performance of the building’s envelope.

- Compliance and Standards for BREEAM: Level 3 thermographers ensure that the thermographic inspections comply with all necessary standards and current regulations, contributing to the overall BREEAM certification process.

By using a Level 3 thermographer, you can be confident in the accuracy and reliability of the thermal survey to your building fabric, ultimately supporting the building’s energy efficiency and sustainability goals.

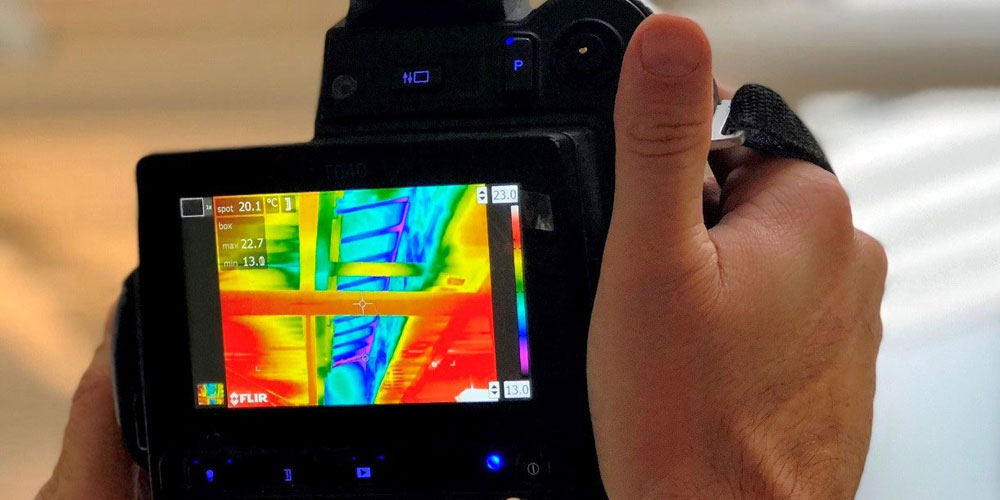

We only use the highest quality thermal cameras

We only use high-resolution, high-sensitivity professional thermal imaging cameras for several reasons:

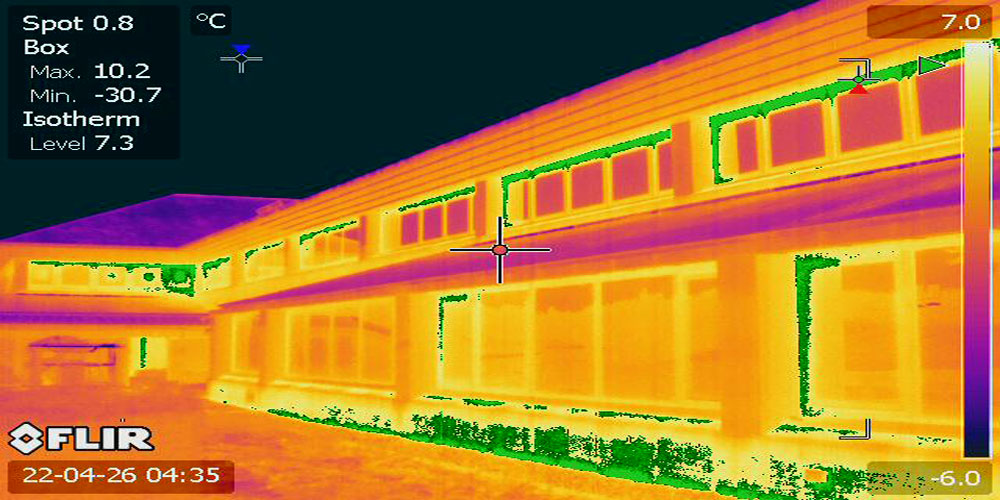

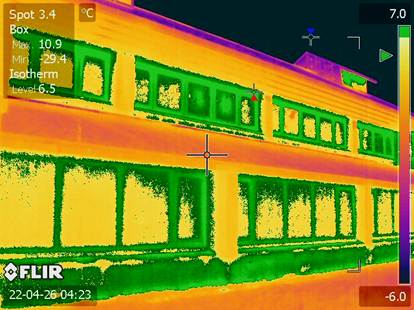

- Enhanced Image Clarity during surveys: High-resolution cameras (640 x 480) provide detailed thermal images, making it easier to identify small temperature differences and detect potential issues.

- Improved Detection Accuracy: High sensitivity, measured as Noise Equivalent Temperature Difference (NETD), allows the camera to detect even the smallest temperature changes. This is essential for accurate thermal analysis.

- Versatility in Applications: High-resolution and high-sensitivity cameras are versatile and can be used in various applications, including building envelope inspections, damp inspections and electrical inspections.

- Better Performance in Adverse Conditions: These cameras perform well in challenging weather conditions, providing reliable thermal imaging even in low visibility situations etc. where lower quality camera may not work, which in turn reduces the chances of aborted visits.

- Efficient Resource Management: By accurately detecting temperature changes, these cameras help in efficient resource management, identifying potential problems quickly and effectively.

The minimum requirements for BREEAM Thermal Imaging Inspections

For BREEAM (Building Research Establishment Environmental Assessment Method) thermal imaging surveys, there are specific requirements to ensure accuracy and compliance:

- Thermographers Certification: The thermographic survey must be conducted by a certified inspector. A minimum of Level 2/Category 2 certification in accordance with ISO 18436-7 is required, although Level 3 is often preferred where possible.

- Temperature Difference: There must be a minimum temperature difference of 10ºC between the inside and outside of the building to effectively detect heat loss or gain across the building fabric.

- Standards Compliance: The survey must comply with the requirements set out in BS EN 13187, which satisfies the BRE SD5076 standard for BREEAM credit.

- Thermal Imaging Equipment: The thermal imaging camera used should be of high resolution and sensitivity to accurately identify thermal anomalies and ensure the integrity of the building fabric.

These specifications help ensure that the thermal imaging survey provides reliable and accurate results to archive compliance, as well as contributing to the overall BREEAM certification of the building.

Our Premium Thermal Imaging Service for BREEAM

Our premium thermographic inspection service even surpasses the requirements of BREEAM, here’s why:

- Supply of an ITC trained Level 3 thermographer

- We use large format FLIR P6n-Series (640×480 resolution) thermal imaging cameras.

- Comprehensive report to include Introduction and fault cover pages, summary problem pages, elevation inventory,

- Detailed fault documentation pages with possible root cause and remedial recommendation (isotherm included if using equations), baseline IR and DC image of every elevation (100% coverage-no isotherm)

- Application of thermal indexing formulas

- Bespoke thermal imaging software

- Eco Friendly Email Report

Please contact us for more information

If you would like to contact us for more information on our thermal imaging services, please contact us on 07775623464, or email us at info@aptsoundtesting.co.uk.