Sound Insulation on Conversion Projects

Many of the dwellings in London and other UK Cities consist of flats that have been converted from large Victorian or Georgian houses, or more recently office blocks. Unfortunately designing for sound insulation is not always shown the highest priority so many converted dwellings suffer from adverse noise transference between the floor and wall partitions. This can be extremely stressful to the occupant’s well-being is a major cause for concern.

APT Sound Testing have helped many of our clients achieve compliance with Part E, by undertaking some simple steps. We can undertake an initial sample sound test of the existing wall and floor construction to ascertain the existing sound insulation levels. Once we have established the sound levels for the existing construction, we can then look at the extent of the acoustic upgrades to attain Part E Compliance. This is much more effective than just forwarding an acoustic design that may be to excessive and expensive, especially if the existing floor and/or wall only needs to improve by a minimal amount such as 1-3dB. By having the existing sound levels of the partitions we can recommend targeted, acoustic upgrades to comply with Building Regulations Part E.

The sound insulation levels required to pass Part E for refurbishment projects are less stringent than new build projects. Instead of 45dB for airborne its 43dB (2 dB less), and for instead of 62dB for Impact Sound Testing its 64dB on new build (2 dB more).

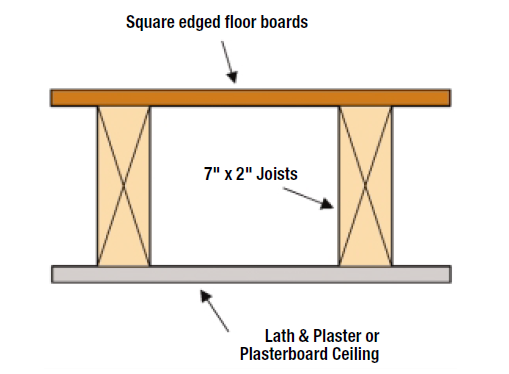

In our experience, refurbishment projects usually achieve 30-35dB for airborne sound and 70dB for Impact Sound during the sample sound test – if the existing construction has not been acoustically upgraded. These figures do not meet the required 43dB & 64dB as stipulated in Part E of Building Regulations. As sound double every 10dB this is a massive failure and major acoustic improvements must be made. Many existing constructions consists of similar construction as shown in as detail 1 below.

Detail 1: Existing Floor Partitions Rated At Approx. 30dB

Improving Wall and Floor Partitions

There are ways you can improve the airborne and impact performance by improving the wall/floor partition’s ability to reduce the amount of sound transmission from one side of a construction element to the other. However; by isolating the different materials may not be enough its own and you may need to improve the mass of the partition as well.

Existing Floor Partitions

In our experience, refurbishment projects usually achieve 30-35dB for airborne sound and 70dB for Impact Sound, if the existing construction has not been acoustically upgraded. These figures do not meet the required 43dB & 64dB as stipulated in Part E of Building Regulations. As sound double every 10dB this is a massive failure and acoustic improvements must be made.

Improving Existing Floor Partitions

To reduce airborne and impact sound transmission usually means adding density and isolation to the floor construction. This can be as simple as adding a drop ceiling consisting of 125mm timber frame. The top of the frame must be a minimum of 25mm below the existing ceiling finish – such as lathe and plaster. Then, to the inside of the timber frame add 100mm of Acoustic Wool and two layers of sound-board tacked to the bottom of the timber frame – all boards to be lapped. This should improve your sound test results by approx. 10-15dB depending on the existing site conditions and quality of the installation.

Existing Wall Partitions

The standard onsite construction for existing internal walls may be a mixture of 100mm masonry with render applied to either side; or, 100mm timber partition with lathe and plaster to either side. Unfortunately, neither of these existing wall constructions will usually have the acoustic properties to pass Part E in their existing state due to lack of mass and poor isolation values.

Improving Wall Partitions

One quick and simple way to improve the acoustic performance of the dividing wall partition is to install a 70mm met-sec partition in front of the existing wall – it’s usually best to install this in the largest room backing onto the dividing partition. Leave approx. 25mm gap between the back of the met-sec and the wall. Then install 50mm acoustic wool to the inside of the met-sec and add two layers of the soundboard to the outside of the met-sec frame, ensuring all boards are properly lapped and the perimeter joints are filled with acoustic mastic.

Taking the above into account is it essential that good acoustic design is addressed right from the start of the refurbishment project, so it prevents delays in handover, i.e. to prevent the dwelling failing the sound testing at building control signoff stage.– a common problem.

If you would like advice on your acoustic design or require sound insulation testing in London, please contact us now on 01525 303 905 or contact us at info@aptsoundtesting.co.uk.