Thermal Imaging for Electrical Equipment Maintenance

Thermal Imaging Inspections for Electrical Equipment Maintenance

Over the last few years facility management companies are seeing the importance of electrical thermal imaging inspections for their predictive maintenance programmes.

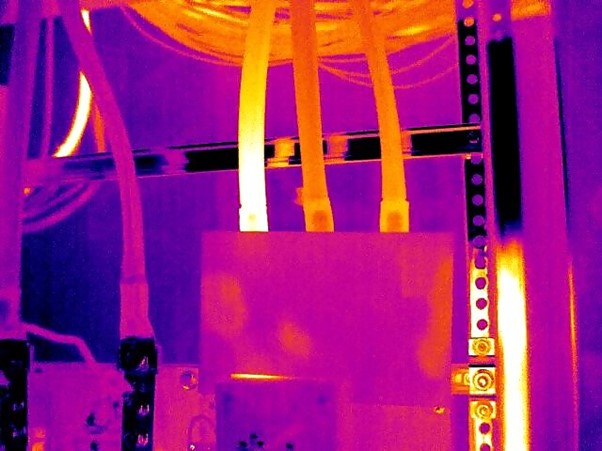

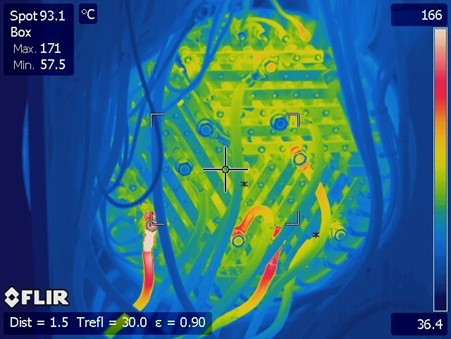

Thermal imaging is essential in electrical predictive maintenance programs because it identifies potential faults and allows for swift inspections and one image can show you various detail unlike using a spot pyrometer where you would have to test individual fuses, this allows maintenance teams to undertake remedial works before critical asset failure.

At APT Thermal Imaging we can analyse your assets and provide you with unique easily understandable thermal imaging reports. That can be rolled out within your predictive maintenance programs. Also, also if you need help analysing the data provided within the thermal inspection report you will have your own dedicated thermographer at hand to explain everything in layman’s terms.

Electrical Maintenance thermography can be used on a wide range of electrical equipment including:

- Distribution boards and fuse boards

- Switchgears and switchboards

- Control panels

- Busbar systems

- Transformers

- High voltage systems

- Batteries

- UPS systems

It’s worth noting that our electrical thermal imaging surveys are carried out while plant and equipment is running. There will be no interruption to electrical supplies and your operations (critical assets) will not be affected while the thermal survey is being undertaken. Our thermal inspections engineers are all certified electrical professionals with extensive experience in thermal scanning of electrical systems.

Benefits of thermal imaging inspections

Thermal imaging inspections can help to prevent fires, explosions or breakdowns. It can find loose connections, overloaded and/or fatigued components, uneven voltage distribution and blockages in cooling tubes of transformers. The principal advantage over other types of testing and inspection is the ease with which components can be checked in a non-intrusive and safer way. Other benefits are normal operations can continue unabated with limited downtime and large installations with hundreds of electrical installations can be covered in a short space of time.

So why do you need electrical thermal imaging inspections.

It’s a very cost-effective way of ensuring that your electrical system doesn’t burn out or break down. This is especially important in industries with high voltage systems and/or where continuity of power is critical to the business, e.g. data centres, banks, utility suppliers, manufacturing, hospitals.

The most common benefits are:

- Extension of equipment/building life

- Less plant (critical asset) down time

- Less energy wasted through inefficient operation.

- The ability to prioritise and better target preventive maintenance

- The avoidance of consequential damage to plant or facilities from fires/short circuits

Our clients include:

- Office Blocks

- Hospitals

- Industrial Plants and facilities.

- Warehouses & Cold Stores

- Shops and stores

Thermal inspections of electrical systems must be carried out by suitably qualified personnel using the correct systems and procedures.

Why pick APT Thermography to undertake your electrical thermal imaging inspection?

All our thermal imaging engineers are trained to level 3, which is the highest level you can achieve as a thermographic engineer. We also use large format thermal imaging cameras; this provides you with the absolute best chance of solving any potential issues by utilising thermographic technology.

Our specification includes:

- Level 3 thermographic certification

- Level 3 qualified thermographers

- Large format FLIR cameras with 45-degree lenses

As our level 3 certified electrical thermal imaging surveyors are trained to a minimum of Level 3 and use only the highest resolution thermal imaging equipment, its means we can keep further away from the danger zone. Our engineers also have a vast amount of experience in conducting this type of survey which further lowers risk. We issue a risk assessment and method statement for each and every survey we undertake.

APT thermography has been carrying out professional thermal imaging surveys since 2010. We only use the highest resolution thermal imaging camera equipment, and our surveyors are all certified Thermographers with strong electrical, building and engineering backgrounds.

Our team of Level 2 & 3 certified professional Thermographers are highly experienced in carrying out thermal imaging surveys and have many years’ experience in all aspects of engineering, construction, maintenance, management, and professional survey work.

Our thermal imaging equipment is the best and most accurate on the market, ensuring we pick up faults that other equipment may miss. Our reports are professionally presented and are clear, concise, and easy to follow. We endeavour to give our clients a first class service every time.

Please contact us for more information

If you would like to contact us for more information on our thermal imaging services, please contact us on 01525 303905 or email us at info@aptsoundtesting.co.uk. Alternatively if you would like more information on how to prepare for your thermal imaging survey, please visit our website here or download our thermal imaging checklist