Room Integrity Testing FAQ’s

Room Integrity Testing Frequently Asked Questions

To try and explain what’s involved in a room integrity test, we have written the following question and answers article:

Q – Why do I need a room integrity test?

A – The test is a requirement of the British Standard for gaseous fire extinguishing systems – BS EN: ISO 14520. Most fire insurers will require evidence that the test has been conducted and the result is satisfactory.

Q – How quickly can a room integrity test be arranged?

A – We can usually undertake a room integrity test within a few days of our client’s inquiry; however, in the case of an emergency, we do offer a 24-hour service.

Q – How do I prepare my protected enclosure for the integrity test?

A – We send out an informative checklist with all our quotations, to help clients prepare for the integrity test.

Q – How long does it take to carry out a room Integrity test?

A – The room integrity test is usually between 1 and 2 hours for a single enclosure.

Q – Will the enclosure integrity test set off alarms?

No, the enclosure test is completely independent of the detection system; however, the room should be isolated and the system turned to manual in line with our room integrity checklist.

Q – Is the room integrity test disruptive?

A – No, it is only necessary to stop access to the room for 10-15 minutes. Personnel – such as IT staff can continue to work in the room. The enclosure test can be paused if immediate access becomes required.

Q – Does equipment such as servers need to be switched off during the room integrity test?

A – No, the servers can carry on running throughout the room integrity test.

Q – Does air conditioning need to be switched off during the enclosure integrity test?

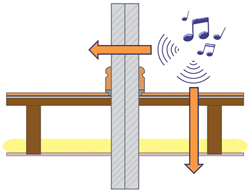

A – Recirculation (chiller) units may continue to run. Air supply/extract ducts passing into the enclosure will need to have the fire dampers closed and/or be temporarily sealed throughout the duration of the test.

Q – Will I get a certificate if I pass the room integrity test?

A – Yes, the certificate will be issued within a few days. This should be retained for possible inspection by the authorities/insurers. We will verbally let you know if the enclosure test has passed or failed whilst on site.

Q – What happens if the room fails the room integrity test?

A – A low-impact smoke test can be undertaken along with a corresponding report to identify the air leakage paths for remedial sealing. Once the remedial works have been undertaken a retest must be conducted to confirm the adequacy of the retention time along with the corresponding pass certification.

Q – Can remedial sealing be done at the time of the enclosure test if its initially failed?

A – Yes, provided the leakage can be swiftly remedially, or temporarily, sealed.

Q – Does APT undertake remedial sealing?

Yes, we can undertake the remedial sealing if so required, or the client can arrange the works themselves.

Q – How often should the room integrity test be done?

A – The relevant British Standard (BS EN: ISO 14520) specifies that the test should be conducted within a 12-month period and/or if any works have been undertaken to the enclosure envelope i.e., new service penetrations are made to the walls, floors, or ceilings.

Q – Is there any corresponding standards for room integrity testing?

A – Yes, the following standard applies to room integrity testing: ISO 14520, NFPA 2001, and ISO 15004

Why use us for your room integrity test?

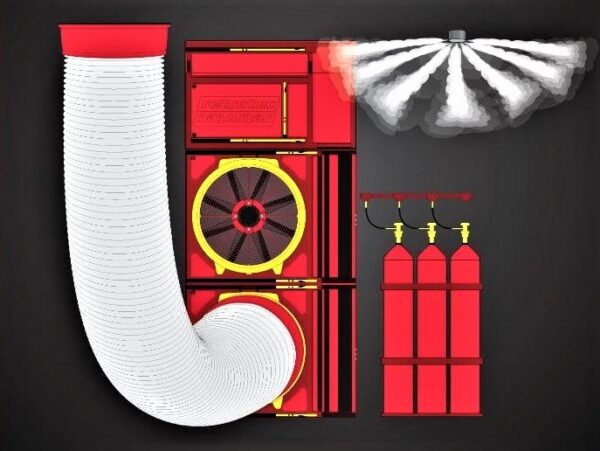

We offer a friendly and cost-effective one-stop solution for all your integrity test requirements. Using the very latest blower door technology, we provide thorough retention reports as well as informative assessments concerning highlighting areas of leakage, advice, and recommendations. We even offer a remedial sealing service should it be required.

If you would like more information on our server room integrity testing, please call us on 01525 303 905 or visit us at info@airpressuretesting.net or visit our Room Integrity Page.