APT Sound Testing – Air Tightness Testing

Air tightness testing, also known as blower door testing, is the process of measuring the amount of air leakage from a building through the building envelope. To try and help our clients better understand and prepare for their air tightness testing, we have tried to explain and answer our customer’s most common questions. For more information on our air tightness testing services you can also visit our Services Page.

What is Air Tightness Testing for Building Regulations?

Air testing is mandatory in the United Kingdom and is governed by Part L of the Building Regulations, this split into two parts; for domestic properties Part L1A should be used and for commercial properties Part L2A should be referenced.

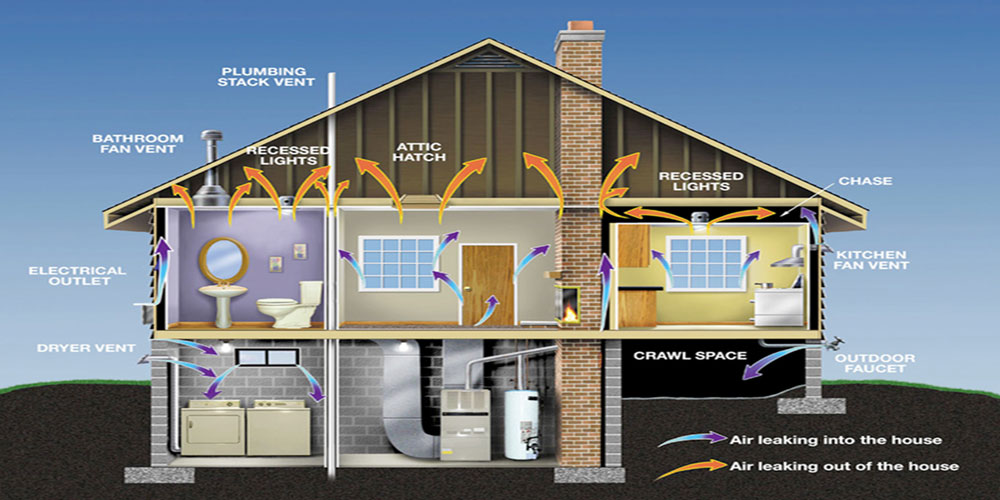

Building Regulations Part L states air tightness testing should be carried to check the air leakage that occurs through a buildings envelope. The air leakage test checks the amount of air that escapes through gaps or air leakage paths through the building fabric. If the building is more air tight, less energy will be being needlessly lost, thus lowering the carbon emissions of the building. Air testing also shows how efficient a building is at retaining conditioned air which will also put less straight on your mechanical and ventilation system. Failing to maintain adequate air tightness can lead to up to 50% of heat loss from within a building to the outside atmosphere.

What air leakage target do I need to achieve?

Most new dwellings and commercial buildings need to achieve an air leakage of 3m3/hr/m2 to 5m3/hm2, this rate would usually be acceptable by building control and your SAP assessor as an acceptable result, although you need to check each your designed SAP assessment as there may be items within your buildings design that that may affect this figure.

How long does the air test take?

Most air tightness tests can be completed in 1-2 hours if they pass straight away; however, tests can take much longer if they initially fail. It usually speeds up the process if customs prepare their buildings in-line with our air tightness checklist as its means we can start the testing as soon as we arrive on site instead of waiting for the client to tape up areas, or make upgrades to the building envelope. We also offer a smoke testing service to locate the air leakage paths within a building envelope which can also take extra time; however this often allows our clients to seal and pass their building at the first attempt even if their building initially fails the air test.

How do you undertake an air tightness test?

The air tightness test is undertaken in-line with Building Regulations Part L1 & L2 and ATTMA TS1 & TS2. Basically we measure the pressure differential across the envelope of the building by means of the temporarily installation of a large fan inside a door panel. Thereafter, a range of static pressures and environmental readings are taken. The fan is switched on and the air pressure in the property is gradually increased or decreased and the differential pressure is recorded at each step, usually from 25 Pa to 70 Pa. The total air flow required to achieve a pressure differential of 50 Pa is calculated and divided by the total building envelope area to provide the leakage rate in m3/h.m2@50Pa.

How do I prepare my building for the air test?

The more complete you’re building the more chance you have of passing the air tightness test at the first attempt. We send our and air test checklist with every quotation to help our client prepare for the testing. It is our aim to help clients pass their air test at the first attempt.

Basically you prepare the building in-line with our checklists and the items below, you will generally have a much better chance of passing the testing at the first attempt.

- The building envelope should be fully complete; this includes walls, floors and ceilings.

- All doors and windows must be fully fitted and able to shut tightly against their seals.

- All electric fittings must be installed and functional.

- All mechanical fittings must be installed and functional.

- Gaps within walls and floors must be sealed.

- All service penetrations must be fully sealed through the building envelope.

- Bathrooms and kitchens must be fully fitted and all service penetrations sealed.

- All mechanical ventilation turned off with grilles sealed.

- All trickle vents to windows and doors must be sealed.

- All fireplaces must be sealed.

- Ensure water is present in soil pipes.

- 240v power must be available on site.

Whether you need air tightness test please contact us on 01525 303 905 or email us at info@aptsoundtesting.co.uk to obtain a no obligation quote. If you need more information on how to prepare your building for the air test please download our air tightness testing checklist.

Alternately, please call visit our website at www.aptsoundtesting.co.uk, for more information on our precompletion testing services