An Introduction & Explanation of BREEAM

An Introduction & Explanation of BREEAM

BREEAM (Building Research Establishment Environmental Assessment Method), first published by the Building Research Establishment (BRE) in 1990, is the world’s longest established method of assessing, rating, and certifying the sustainability of buildings. More than 550,000 buildings have been ‘BREEAM-certified’ and over two million are registered for certification in more than 50 countries worldwide. BREEAM also has a tool which focuses on neighbourhood development.

The BREEAM Assessment

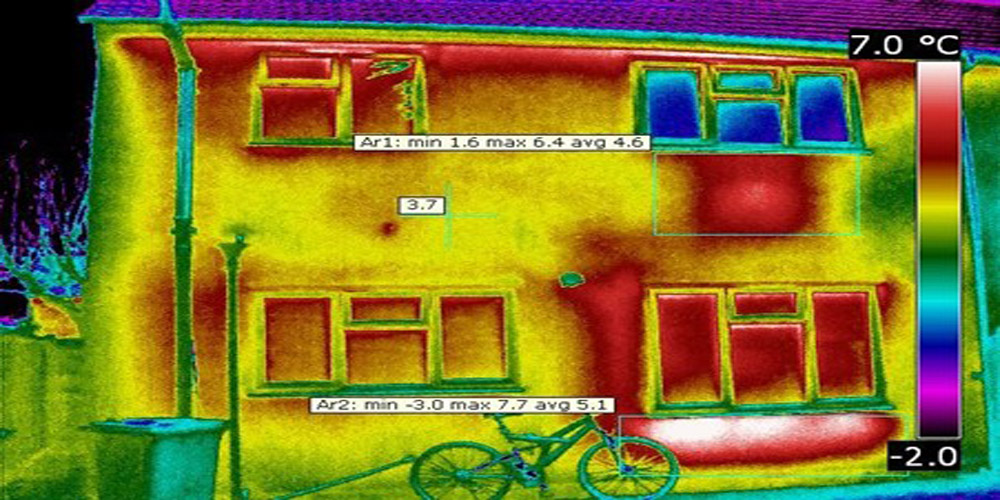

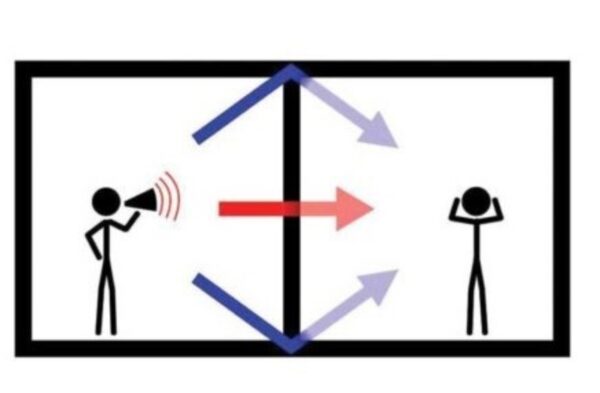

BREEAM is an assessment undertaken by independent licensed assessors such as APT Sound Testing using scientifically-based sustainability metrics and indices which cover a range of environmental issues. Its categories evaluate energy and water use, health and wellbeing, pollution, transport, materials, waste, ecology and management processes. Buildings are rated and certified on a scale of ‘Pass’, ‘Good’, ‘Very Good’, ‘Excellent’ and ‘Outstanding’.

It works to raise awareness amongst owners, occupiers and designers of the benefits of taking a sustainable approach, providing a framework to help them to successfully adopt sustainable solutions in a cost-effective manner, and provides market recognition of their achievements. It aims to reduce the negative effects of construction and development on the environment.

BREEAM has expanded from its original focus on individual new buildings at the construction stage to encompass the whole life cycle of buildings from planning to in-use and refurbishment. Its regular revisions and updates are driven by the ongoing need to improve sustainability, respond to feedback from industry and support the UK’s sustainability strategies and commitments.

Highly flexible, the BREEAM standard can be applied to virtually any building and location, with versions for new buildings, existing buildings, refurbishment projects and large developments:

BREEAM New Construction is the BREEAM standard against which the sustainability of new, non-residential buildings in the UK is assessed. Developers and their project teams use the scheme at key stages in the design and procurement process to measure, evaluate, improve and reflect the performance of their buildings.

BREEAM International New Construction is the BREEAM standard for assessing the sustainability of new residential and non-residential buildings in countries around the world, except for the UK and other countries with a national BREEAM scheme (see below). This scheme makes use of assessment criteria that take account of the circumstances, priorities, codes and standards of the country or region in which the development is located.

BREEAM In-Use is a scheme to help building managers reduce the running costs and improve the environmental performance of existing buildings. It has two parts: building asset and building management. Both parts are relevant to all non-domestic, commercial, industrial, retail and institutional buildings. BREEAM In-Use is widely used by members of the International Sustainability Alliance (ISA), which provides a platform for certification against the scheme. The newest version v6, available from 2020 includes also Residential programs.

BREEAM Refurbishment provides a design and assessment method for sustainable housing refurbishment projects, helping to cost-effectively improve the sustainability and environmental performance of existing dwellings in a robust way. A scheme for non-housing refurbishment projects is being developed and is targeted for launch in early 2014. The launch date will be announced once the piloting and independent peer review processes has been completed.

BREEAM Communities focuses on the masterplanning of whole communities. It is aimed at helping construction industry professionals to design places that people want to live and work in, are good for the environment and are economically successful.

BREEAM includes several general sustainability categories for the assessment:

>>> Management

>>> Energy

>>> Health and wellbeing

>>> Transport

>>> Water

>>> Materials

>>> Waste

>>> Land use and ecology

>>> Pollution

Home Quality Mark was launched in 2015 as part of the BREEAM family of schemes. It rates new homes on their overall quality and sustainability, then provides further indicators on the homes impact upon the occupants ‘Running costs’, ‘Health and wellbeing’ and ‘Environmental footprint’.

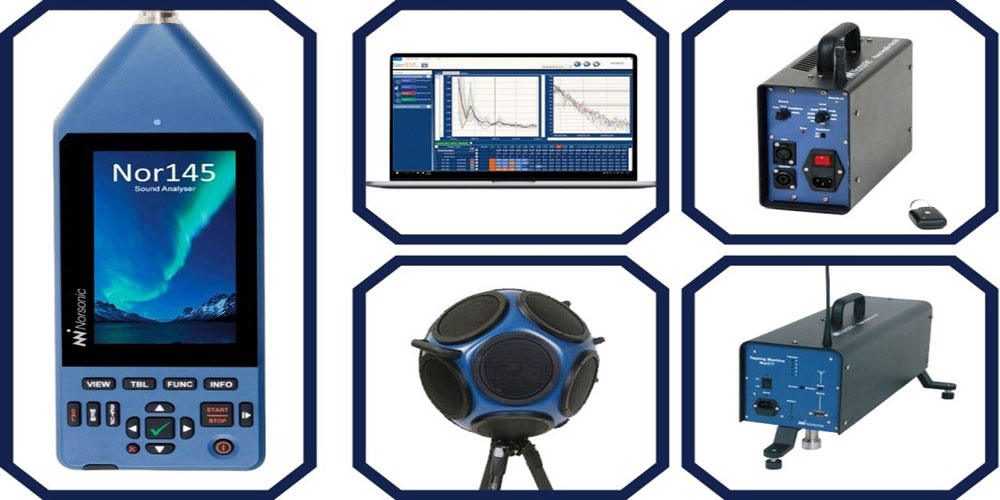

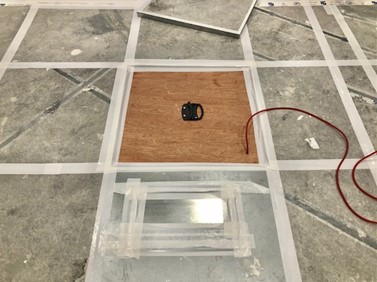

Here at APT Sound Testing we have been providing indoor air quality services such as post-construction air quality testing and indoor air monitoring for a number of years. We have assisted many customers in gaining their BREEAM and other compliance credits through our air quality plan and BREEAM air quality testing services.

For more information please call one of our friendly team today on 01525 303 905 or Contact Us using our online web form. We are here to help!