Thermal Imaging Surveys In London

From our Clapham office in Central London, we can carry out your Thermal Insulation Testing, professionally with our efficient experienced team of thermography engineers. We can provide an excellent service to the South East area from our Clapham base, covering many areas including, Central London, North London, South London, East London, West London, Croydon, Guildford, Slough, Reading, Maidstone and Hemel Hempstead.

Request a call from our experienced team of thermographic engineers or call us on 01525 303905.

APT Sound Testing provides specialist thermal imaging surveys to customers through all industry sectors throughout the UK including construction and facility management projects throughout London and the South East.

Specialising in electrical thermal imaging surveys and building thermography in London, APT sound Testing is one of a few companies that only use surveyors that are trained certified to a minimum of ITC Level 2, which is the minimum requirement to undertake BREEAM Thermal Inspections throughout London and the rest of the UK for practising thermographer’s.

We have over 15 years of experience carrying out building thermal imaging surveys in support of industrial and commercial applications, our thermal inspections reportage contains the required reporting structures to satisfy the requirements expected by Construction and Insurance Companies, Facility Managers, Building Control and BREEAM 2011 Assessors etc.

Here at APT Sound Testing we realise that thermal imaging inspections can be vital in establishing potential defects in your buildings at the earliest possible stage. This can save you time and money during future operations together with reducing the risk of making the wrong decision and potential building shutdowns.

The combination of highly trained and certified and experienced thermographic surveyors as well as high specification calibrated equipment, guarantee our customers the best possible thermal imaging survey report to meet all of your needs. Our thermal imaging team make sure that customer satisfaction comes first and our surveys are carried out with the upmost thoroughness and expertise.

Thermal Imaging to show Continuity of Insulation

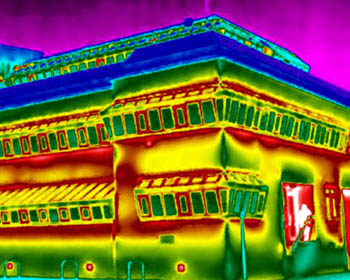

Thermographic surveys can also be used to demonstrate compliance with Part L1 and L2 (2006 – current edition) of the Building Regulations. These regulations require that both domestic residential and commercial properties be able to demonstrate the continuity of thermal insulation to the entire building envelope, thermal imaging can be used to show compliance with these requirements without having to open up or remove parts of the structure that may otherwise cause damage and delay.

Surveys can quickly and effectively detect areas of missing, moisture-laden or damaged insulation in walls, ceilings, floors, etc. This is particularly beneficial for buildings with poor energy ratings, where improvements can be focused on the most relevant areas.

BREEAM Thermographic Surveys in London

BREEAM Thermal Surveys must be conducted by a thermographer listed on the UKTA website as a certified Level 2 PCN thermographer. Out thermographer’s hold Level 3 certification so they more than meet the minimum requirement.

The weather conditions and planning for this type of survey are important. The thermal survey should comply with BS EN 13187 and other good practice. It is a requirement of the BREEAM scheme that a copy of the thermographer’s Level 2 certification is provided as evidence in addition to the thermography report.

Combined Air Tightness and Thermal Surveys in London

One of the major areas Building Regulations Part L relates to building efficiency and the air tightness of the building envelope. To comply with these new regulations, buildings have to be tested by a certified air tightness company to check for excessive leakage. When Thermal imaging is used in tandem with air tightness testing it becomes a very beneficial method for visualising and located were individual air leakage paths are occurring within the building envelope.

APT Sound Testing provides combined air tightness and thermographic testing of domestic and commercial buildings in London. In addition to this, when conducting a normal thermographic heat loss assessment, a blower door normally used for the air tightness testing, can be used by the thermographer to pressurise or depressurise the building to improve the accuracy of the thermal imaging survey. A combined air and thermographic test is the ultimate thermal assessment of the building. Using our combined tested methods we can uncover a higher level of information on uncontrolled air movement within the building structure, for example behind plasterboard, up through the floors or within cavities around the building. These may not be felt as draughts, but do result in excessive heat loss and a cold feeling in parts of the building and as such are very important for the occupiers of the building.

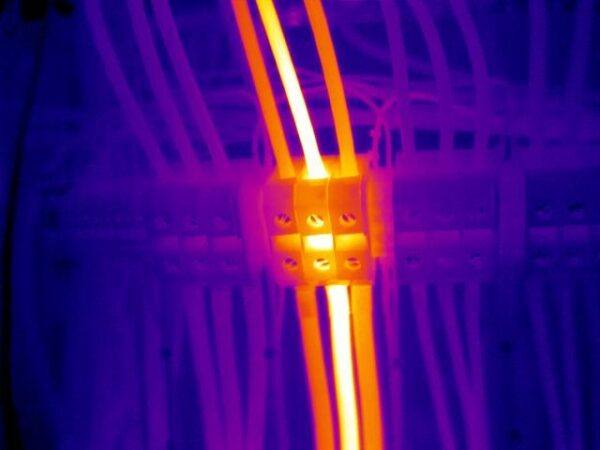

Thermal Electrical Inspections in London

Thermal imaging on electrical installations is a major contributor to improving safety and identifying problems before they happen in the workplace. Power and lighting distribution boards should be checked 6 monthly, annually or biannually. Many insurance companies require a thermal imaging survey to be completed to help reduce their losses, especially within commercial buildings.

Vibration and thermal stress can cause connections in power distribution systems to loosen, contamination can corrode these connections; both factors increase the resistance of the connection making every connection a potential candidate for overheating. Furthermore, if the problem is allowed to persist, a situation called “glowing connection” can arise which can generate significant heat without tripping the safety protection on that circuit.

Fire avoidance: Loose or overloaded circuits can arc, get extremely hot, melt cable insulation and eventually catch fire. Thermographic inspections can instantly identify this, with this information you can then replace or repair the components before they fail, reducing or preventing facility downtime and/or costly repairs.

The best way to keep up this predictive & preventative maintenance is by incorporating them into a regular condition-based monitoring program, this, in turn, will reduce or even eliminate unplanned shutdowns. We can set up thermal imaging monitoring programs for your London facilities and remind you as and when they are required.

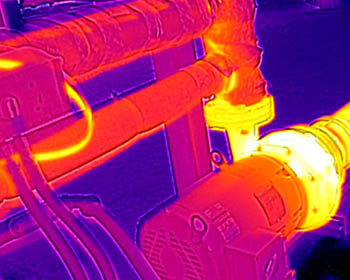

Mechanical Infrared Inspection in London

Undertaking Infrared inspections of mechanical rotating equipment can identify excess heat caused by friction and wear. Some friction induced heating is normal in mechanical systems, but when it increases above typical operating temperatures, it can be a leading indicator of wear and a predictor of component failure.

Thermal imaging detects this heat and identifies problems while they are in their early stages, preventing a catastrophic failure. Early detection provides your maintenance the opportunity to take corrective actions to prevent failure and downtime on pumps, gears, bearings, gearboxes, conveyors couplings and heat exchangers etc.

We can undertake regular condition-based monitoring program, this, in turn, will reduce or even eliminate unplanned shutdowns. We can set up thermal imaging monitoring programs for your facilities and remind you as and when they are required.

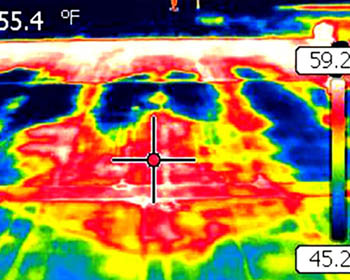

Flat Roof Thermography Surveys in London

Infrared thermography can be used as a non-destructive method for leak detection in flat roofs. With use of thermal imaging cameras, our qualified Infrared Thermal Imaging Technicians will scan the roof and monitor the difference in temperature between wet and dry materials, helping to locate areas of water ingress. This can also flag areas which may be unstable due to hidden rot, and areas which may require further investigation.

A typical flat roof has little or no moisture between the roof membrane and the insulation/ decking, so when a leak occurs, moisture enters the roof and is absorbed by the insulation or decking. Dry materials heat up and cool down faster than wet materials, and the damp areas require more heat to increase their temperature/ take longer to release their heat. We use thermal imaging techniques to highlight such changes and identify both the source and extent of the moisture ingress. Typical roof decks can be made from a multiple of materials such as steel, wood or concrete; the material of the roof deck does not affect the thermal survey in London.

APT sound testing works with many flat roof companies within London to help highlight problems on new/existing flat roof construction. We provide a rapid and accurate service, provided both diagnosis and accurate reportage for minimal disruption to our customers.

Thermal Imaging for Part L Compliance in London

Thermal imaging is the only practical method for checking a completed building for its compliance with Building Regulations Part L in all areas. This part of the building regulations identifies the required performance of the insulation systems in the walls, floor and roof of any new building.

APT Sound Testing can provide a thermal imaging survey to show in a qualitative manner that there is reasonable continuity of insulation-in other words, to show that there are no areas with insulation missing. If there are areas of missing insulation, the thermal imaging survey will show where they are and how big they are. We can also assess the actual performance of the insulated wall or roof, as constructed and provide a U-value for parts of the building. It can be problematic and unrealistic to measure exact U-values, however we do have methods to calculate alternative measures of the insulation factor of a wall and some indication versus an expected U-value can be provided. We are happy to discuss this with customers who want to know more about this service.

Why our Level 3 Certified Thermographers produce better reportage

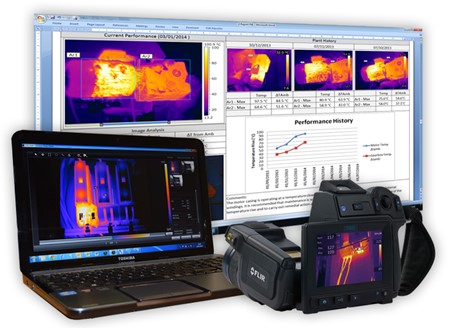

In our experience highly qualified thermographer’s produce higher quality and more technically consistent thermography inspection reports. Our highly trained Level 3 thermal engineers can troubleshoot, calibrate equipment, interpret data, and create reports.

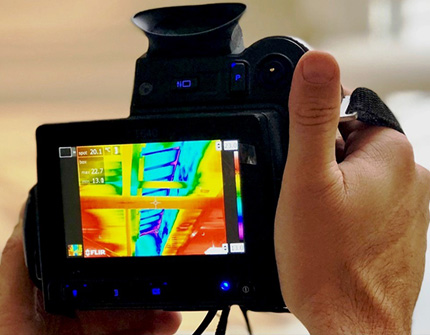

When you are employing a thermographer, you should check to see that they incorporate the high specifications possible for their inspections. Are they certified to Level 3 and do they use large format FLIR thermal imaging cameras?

Our thermal inspection specification includes:

- Level 3 thermographic certification

- Level 3 qualified thermographers

- Large format FLIR cameras with 45-degree lenses

- Detailed, easy to follow thermal imaging reports

While thermographer certification represents an investment, it is an investment that typically pays in the long run. Not only do Level 3 certified thermal engineers produce higher quality inspections, but their thermal inspections are also more technically consistent! Uncertified, or lower-level thermographers are more likely to make costly and even dangerous mistakes! these mistakes may even result in serious consequences, such critical problems being completely missed. While the appropriate qualification is important, written inspection procedures are also important for attaining high-quality results and reportage.

Three reasons for undertaking Thermal Imaging Surveys in London

Thermal imaging surveys to assess the integrity of building envelopes are usually required for one of three reasons.

1. To help diagnose and record suspected problems with the building envelope or comfort levels – Where there are suspected problems with the building envelope such as moisture ingress, condensation and mould growth or where there is the perception that the thermal efficiency isn’t what it should be, the use of thermography can provide excellent visual and quantitative evidence of the causes of the suspected problems which can be used for targeted remedial works by the customer.

2. To identify potential improvements to reduce energy costs and CO2 emissions within the buildings – On existing buildings, thermography can be used to assess the overall performance of the individual building envelope. Once this has been established, informed decisions can be made on improving energy efficiency. If required, in depth analysis can also be undertaken to estimate the potential cost and CO2 reductions if particular improvements are undertaken to the existing building.

3. To demonstrate compliance with the construction specification on newly constructed buildings – Building Regulations Part L and sustainability assessments such as BREEAM are starting to include thermal inspections as part of the Building Specification. Thermal imaging surveys are help with quality assurance and to achieve the required sustainability rating.

Our usual sequence for undertaking our Thermal Imaging Service

1. APT’s friendly and efficient office thermal imaging team will take your information, and provide you with the contact number for your dedicated thermal engineer. Your engineer will deal with you throughout your works.

2. Once we have established whether your project, is an emergency or not, we will then act accordingly. We will require confirmatory notification of requirement for our thermal imaging engineer, to attend site prior to their attendance and inspection. This is so we can identify the type of thermal imaging surveys required along with potential access issues etc.

3. Our thermographer will travel to your London site and carry out the thermal imaging survey, depending on the nature of the work and the client’s instruction. The usual information gathered is recording, making reference to image numbers, equipment locations and details, load readings, temperatures, anomalies, and suspected root causes. In addition, our thermography inspectors will record an IR and DC image of every electrical panel inspected, along with our bespoke software we can open up a trending programme on the electrical equipment, this becomes a base line for later reference. It also satisfies your insurers that thermal imaging inspection has been completed correctly.

4. On completion of our London thermal imaging survey, our thermographer will issue an IR Thermography report to the facility manager/maintenance supervisor and make them aware of any potential problems, specifically critical issues that require immediate notification and client action.

5. Our reports are issues within 72 hours following the survey, APT Sound Testing will provide the full IR Thermography report via email in pdf format, unless otherwise request. We can produce quicker reports in the case of emergency thermal inspections – these are available upon request.

Thermographic Checklist for customers in London

What’s involved in a thermal survey?

The thermal survey would aim to be carried out under the recommended environmental conditions as detailed below this would be subject to weather conditions.

- Thermal Images would be captured of each elevation of the building from the outside with assessment/analysis included within the report.

- The building would then be scanned from the inside with thermal images and analysis recorded if anomalies are identified during the thermographic survey.

- Safe access and clear working areas will be required, especially if mechanical access machinery is to be used to aid the thermographic survey (i.e. in the event of surveying roofing or other difficult to reach areas).

- A minimum temperature difference of at least 10 degrees Celsius is required between internal and external areas. This may require heating systems to be on for at least 8 hours prior to commencement of survey.

- The thermographic survey should usually be conducted at night or early morning when environmental conditions are suitable and solar loading effects have completely disappeared to the building envelope.

- Please tape all ventilation within the building envelope as this will enable the engineer adequate time on site – ventilation includes intermittent extracts, mechanical extractors, fire vents, chimney openings, air bricks trickle vents, roof window vents, inlet – outlet mechanical ductwork- please note this list is not exhaustive and there may be other areas that need to be sealed.

- Ensure the building envelope is complete. All Glazing, external doors and cladding to be complete. All penetrations through the building envelope to be sealed.

Recommended Environmental Conditions

- Temperature difference across building fabric >10°C at the time of the thermographic survey.

- Temperature difference across building fabric >5°C for 24hrs preceding the thermographic survey.

- External air temperature to be within +/- 3°C during the thermography survey.

- External air temperature to be within +/- 10°C for the preceding 24hours.

- The external envelope surfaces to be free from solar gain.

- No precipitation just prior to or during the thermographic survey.

- Wind speed to be less than 10mph during the thermography survey.

- Ensure all building envelope surfaces to be inspected are dry during the thermographic survey.

General Thermal Survey Information

a. The thermography survey will generally be undertaken following completion of the building when site risks are substantially reduced just prior to building handover. It is important that the thermography survey is undertaken in a safe, planned and methodical manner.

b. The thermal survey requires the thermography engineer to view an image of the building through the view finder on the thermographic camera. Even though it is likely that the floor surface will be level and clear of obstruction during this stage pf the project, nonetheless special care should be taken to view the image in the camera display whilst at standstill.

c. If a large area of building envelope is under review, and mobile equipment is required to facilitate safe access etc. then extreme care is required and the surveyor must be attended by an assistant acting as banksman.

d. In many cases the thermography survey will be undertaken externally at night or early morning, in darkness. Special care must be taken to ensure that high-visibility clothing is worn throughput the survey. Assistance must be sought where risk of collision with vehicles exists.

e. If any roof surveys are required, they should only be undertaken by walking over the surface of the roof under the accompaniment of an assistant or the client’s trained representative. Safety harnesses must be worn at all times as and when it’s a requirement.

f. During the thermographic survey our engineer will collate the relevant information, recording the thermographic images, photographic images and taking notes to enable a concise report of the findings which will be compiled on return to our office.

Thermal Imaging Surveys in London & Home Counties

To learn more about our London thermal imaging surveys and how they can help you maintain your home better, call APT Sound Testing today. We have the equipment and experience necessary to identify underlying maintenance issues that can lead to expensive and unforeseen maintenance costs. Whether it BREEAM Thermal Imaging Survey be a Leak Detection Survey, an underfloor heating survey, a damp survey, or an energy efficiency survey, please contact us today and see how we can assist you.

Learn more about our Thermographic Inspection Service

To learn more about our London thermal imaging surveys and how they can help you maintain your home better, call us on 01525 303905. We have the equipment and experience necessary to identify underlying maintenance issues that can lead to expensive and unforeseen maintenance costs.

Whether it BREEAM Thermal Imaging Survey be a Leak Detection Survey, an underfloor heating survey, a damp survey, or an energy efficiency survey, please contact us today and see how we can assist you.