Finding Building Defects with Thermal Imaging Surveys

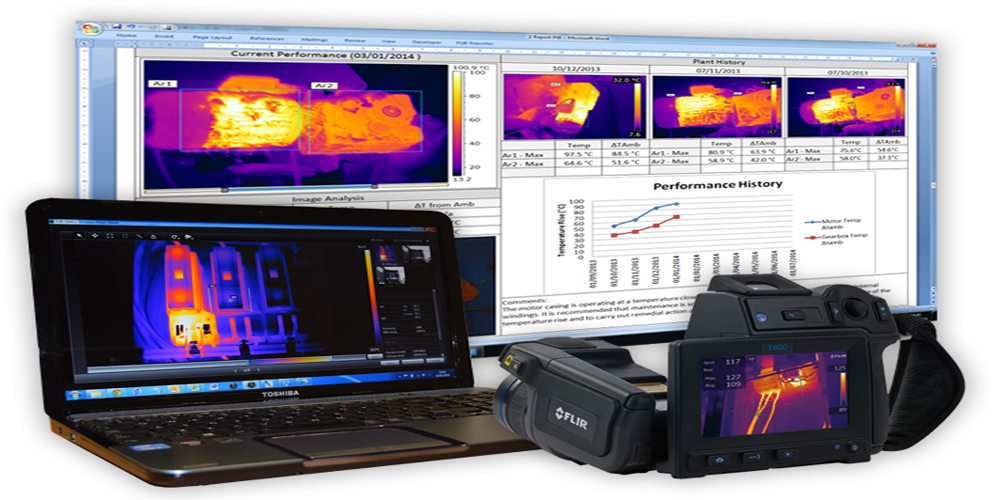

Thermal imaging surveys are a great tool for identifying building defects in new or existing commercial building. They can pick issues within your building envelope, such as damaged or missing insulation,

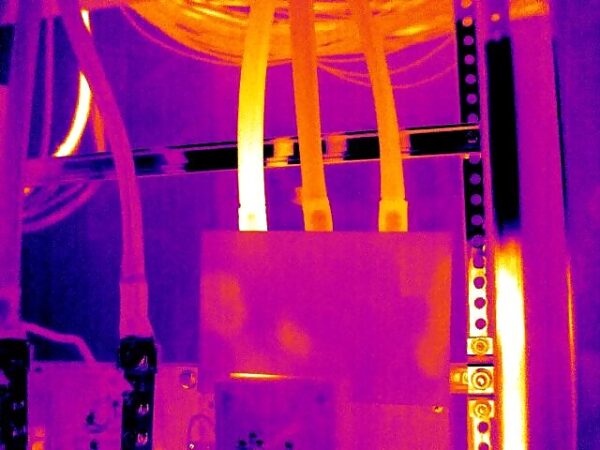

Thermal imaging inspections are useful for spotting leaks in pipes, and detecting moisture damage such as dampness in floors walls, and ceilings, and is often instructed by insurance companies to determine whether there are any hidden dangers in buildings that could cause major damage such as old electrical and mechanical systems.

Common building defects found with thermal imaging surveys

There are literally hundreds of varying defects that can be found using thermal imaging inspections, here is a list of the most common issues found in residential and commercial buildings:

- Faulty Electrical Systems – thermal imaging is good for fault diagnosis in electrical systems. Components can be checked in a live state with little danger to the user, there is no effect on the components or interruption in any processes the electrical system may be controlled, thus no downtime for server rooms and/or manufacturing plant etc.

- Leaky Pipes – leaking pipes in walls, floors and ceilings allow you to quickly target and rectify the issue before it causes too much damage to your building

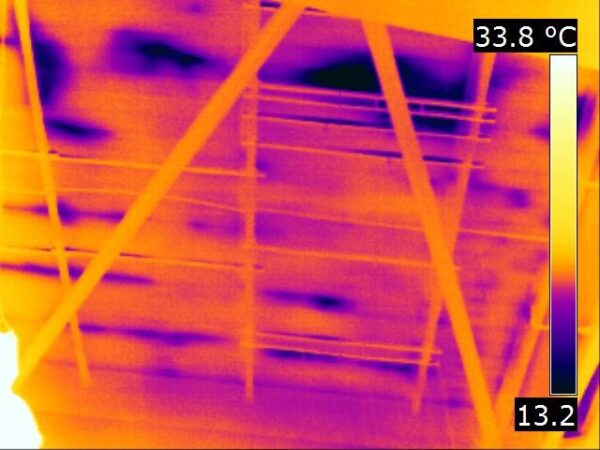

- Building Construction Defects – thermal Imaging surveys can identify construction faults such as damaged or missing insulation in cladding and/or cavity walls.

- Air Leakage Paths – Identifying air leak paths in your building fabric during your building survey can help you keep your building warmer and more insulated, often resulting in decreased energy costs.

- Moisture Issues – Thermography can help identify moisture problems on the interior or exterior of the property which can affect the drying of buildings.

- Flat Roof Leaks – Thermal Surveys can help reduce the chance of possible leakage in flat roofing before it becomes a wider issue.

- Damp Issues – Using thermal cameras, you are able to accurately identify areas of damp, allowing you to target and rectify the issue from its root cause.

- Building Renovations – Thermal Imaging can help identify which parts of a building need improving, saving time and money on unnecessary restoration works.

- Leaking Pipes – thermal imaging can help you identify locations of leaking pipes in walls, floors and ceilings allowing you to quickly target and rectify the issue before it causes too much damage to your building.

We provide high-quality Thermal Imaging Inspections

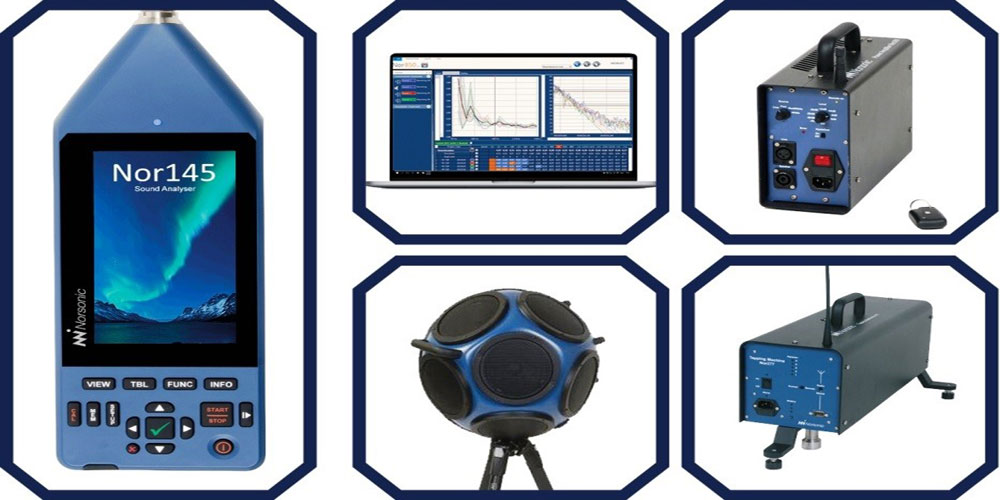

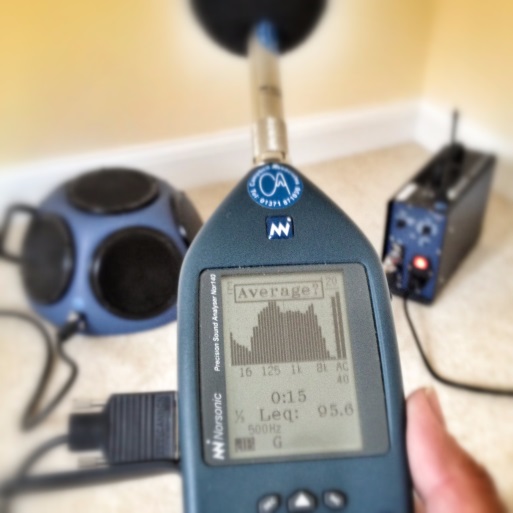

Our experienced and highly qualified thermal imaging surveyors produce higher quality and more technically consistent thermography inspections. Our Level 3 engineers can troubleshoot, calibrate equipment, interpret data, and create reports that are both informative and easy to follow.

When you are employing a thermographer, you should check to see that they incorporate the high specifications possible for their inspections. Are they certified to Level 3 and do they use large format thermal imaging cameras?

If you would like further information on out thermal imaging inspection services, please contact us at 01525 303905 are or infor@aptsoundtesting.co.uk or visit our website at www.aptsoundtesting.co.uk and download our thermal imaging checklist