Thermal Imaging Heat Loss Surveys

Thermal Imaging Survey helps track down the sources of heat loss in your home or commercial building, whether that be poorly installed or missing insulation, cold air infiltration into voids or direct draughts through the building envelope.

It’s worth noting that over 60% of the UK’s residential and commercial properties suffer from some form of heat loss. Heat loss can be due to many factors; however, the main ones are:

- Missing wall, floor, and ceiling Insulation – Possible causes include damage or inadequate installation and water ingress.

- Thermal Bridging – The movement of heat through the building structure tvia material bridging

- Windows and Doors – poor draft excluders and poorly installed fixtures and fittings allowing heat escape through gaps.

- Structural Integrity – roofs and walls and floors

Excess heat loss can result in increased energy usage which means higher bills to the end user/occupiers as well unhappy occupants experiencing drafts and cold areas within the building. If there are unexplained cold areas in your building and/or you think your energy bills are too high, then you should consider a Thermal Imaging Heat Loss Survey.

The main issues are:

Insulation problems

Poor Insulation is one main reasons for heat loss, the other being poor airtightness. Unfortunately, poor insulation is not usually visible to the naked eye, being hidden within the fabric of the building.

Thermal imaging inspections can quickly reveal where issues have arisen during the construction process, such as poorly installed, missing, or damaged insulation

Draughts

Draughts are very uncomfortable for occupiers and are usually an indication of heat loss through the building envelope. Like insulation problems identifying the source of draughts is not always obvious. In many cases air can be coming into the building via multiple gaps and cracks in walls, floorboards and doors, windows.

A thermal imaging survey can quickly identify cold traces that give away the air leakage paths, where the cold air is entering the property.

Heating and damp problems

A thermal imaging inspection can pick up on air trapped in the heating system and unbalanced heating systems – radiators etc. it can Also identify leaking underfloor heating and uninsulated pipework hidden in service voids.

Thermal imaging can also pick up problems with damp, although it is recommended that this is supplemented with an inspection using specialist testing equipment, such as combined thermal imaging and moisture meters.

Common air leakage paths found during thermal surveys

There can literally be hundreds of air leakage paths through building envelopes, here are some of the most common areas we have previously identified during heat loss surveys:

- Via ductwork and service penetrations where services enter the building.

- Around the bottom of the external cladding.

- Faulty or unpowered roof lights not shutting properly.

- Wall/floor junctions under kitchen and utility room cupboards.

- Around SVP and waste pipe penetrations passing through external walls and ceilings.

- Around services that pass behind all IPS panels in toilet/shower areas.

- Service riser cupboards that are not re compartmentalised from the rest of the building.

- Unsealed bath and shower tray panels.

- Damaged or poorly installed Background trickle ventilators, passive ventilation systems and any permanently open uncontrolled natural ventilation openings.

- Poorly installed ductwork to mechanical ventilation and/or air conditioning systems.

- External door/windows that are not shutting tightly against their own seals and the frames are not sealed against the surrounding walls.

- Internal doors that are not sealed at the floor junction.

- Internal sliding doors with unsealed pocket boxing into walls.

- Dot & dab plasterboard that has a unsealed gap In between the bottom of the plasterboard and the structural floor.

- Unsealed perpendicular mortar joints

- Unsealed cavities and roof voids as well as holes that bridge the cavity or roof void.

- Unsealed block work that has not been painted

- Poorly finished cladding at perimeter joints of individual sheets, areas where it meets at different angles.

- Around areas within ceilings voids, to include steel penetrations, service penetrations and the perimeter/eaves junction.

- Around uninstalled and/or unsealed sockets, and light fittings housed in plasterboard.

Use a thermal imaging company with experience of heat loss surveys.

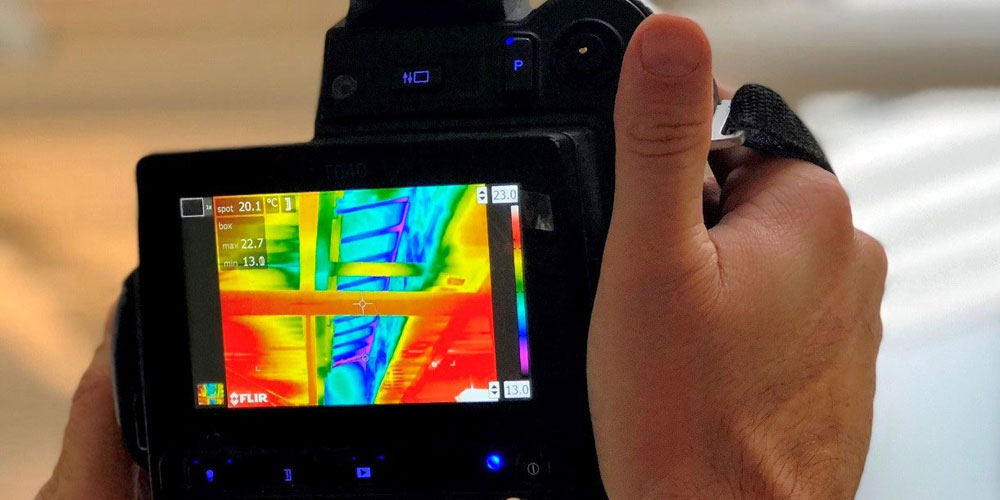

At APT Sound testing, we have 20 years’ experience identify heat loss using thermal imaging surveys. Our engineers hold a Level 3 certification which is some of the highest in the industry. We use the latest high resolutions cameras costing over twenty thousand pounds.

Our thermal specification includes:

- Level 3 thermographic certification

- Level 3 qualified thermographers

- Large format FLIR cameras with 45-degree lenses

All of our thermal surveys are followed up with an extensive report, identifying problems and suggesting resolutions. We can also supply drones that are equipped with thermal cameras, perfect for identifying heat loss in roofs and elevated areas of a building were safe access is difficult and expensive. We can undertake Thermal Imaging to identify heat loss in all types of buildings from large commercial buildings to office spaces, schools, and historic houses.

Do I need an internal or external thermal survey?

Clients often ask do they need an internal or external thermal survey to best identify heat loss in their building? There is an easy answer to this question – Both!

Wherever possible its always best to gather the most gather information possible at the time of the survey, so to allow for this a thermal scan of both the inside and outside of the building needs to take place, to ascertain what’s happening both the internal and external building envelope. by undertaking an external and internal survey, we can gather different and complimentary data for both sides of a wall or roof. In many cases an internal survey will pick up different issues to an external survey and visa-versa.

Sometimes, it may not be possible to undertake both types of surveys, such as surveying a flat on the 20th floor of a high-rise block; however, wherever possible we will always strive to inspect both sides of every wall and roof we survey.

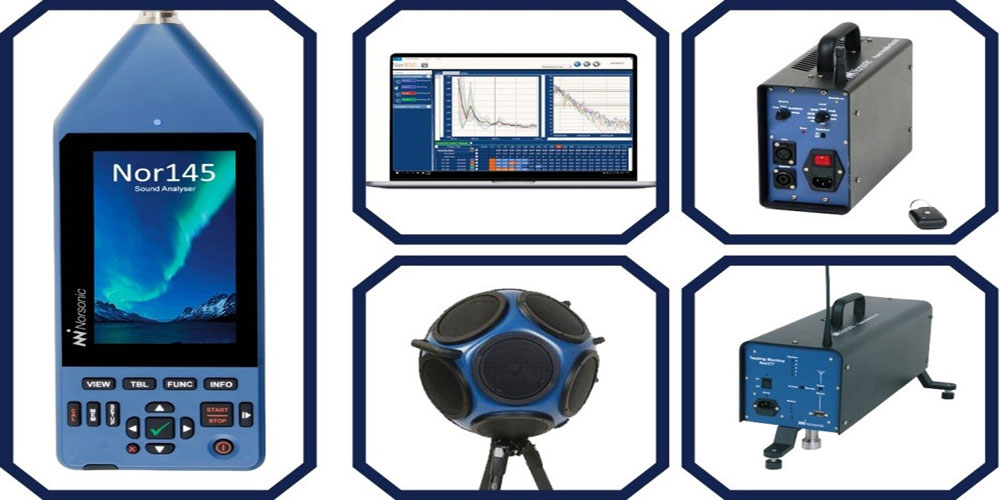

Is combined thermography and air leakage testing worthwhile?

Is combined air tightness and thermography worthwhile? A resounding YES! It’s a very powerful combination.

As air leakage testing becomes more important for compliance with Part L requirements and reduce energy loss there is a natural partnership between thermal imaging and air tightness testing; so, why is this?

Thermal imaging and air tightness testing are not interchangeable – they are important in their own right – but they provide a similar goal, to locate sources of heat loss in buildings. In many cases, thermal inspections can help locate the air leakage paths that the blower door test has highlighted by pressuring the building. Combining the best parts of air tightness testing and thermography allows for clearer and more defined results to be generated to better highlight and target air leakage points around dwellings and commercial buildings.

APT Sound Testing is UKAS accredited to undertake air tightness testing and we hold Level 3 thermal imaging certification. This allows us to provide a combined service to clients for combined thermal imaging and air tightness testing for compliance with BREEAM or other requirements.

Thermal Surveys to Save Money & Energy

Using our well trained and equipped thermography engineers can quickly and accurately locate faults and provide the information you need to target the correct repair first time, saving you huge sums of money over traditional destructive investigations! Our Thermal Imaging Surveys highlight where your home or office building is losing massive amounts of heat and recommend where you can make improvements to conserve energy and keep occupiers happy!

Thermal Surveys can be extremely useful when acquiring a new or existing building such as:

- Identifying defects in a new or existing building, prior to purchase allowing you to negotiate a better price with the seller, considering the costs for the remedial works.

- Check for upgrades to the building and structure.

- To check if the cost of maintenance outweighs the use and value of the building.

It doesn’t matter if you are halfway through a build or taking over a hundred-year-old block of flats, we can start to save you money by identifying heat loss quickly and with no fuss. A quick survey with our thermal cameras will identify areas of heat loss and you can then put actions into place to ensure your energy consumption goes down. The short-term costs of extra insulation will save you money in the long run.

Our thermal imaging heat loss surveys roadmap.

- APT will book in a convenient time to visit your project, allowing for optimal weather conditions – if it’s cold enough. In the event that the weather forecast is unsuitable then we will contact you to rearrange the thermal survey visit.

- When we arrive at site, we will undertake a site walk and discuss the problems you (or your building occupiers) are encountering with heat loss and draughts.

- Using the collected information, we will carry out a thorough thermal imaging survey of your building both inside and out – you should allow 1-3 hours for the survey depending on the size of your building.

- The detailed thermal imaging reports are typically supplied in 24 to 48 hours. You will receive your thermal imaging report in PDF format – this includes the images we have captured, along with our interpretation of the problems indicated.

What information do we need to undertake the thermal survey?

The usual information we require prior to being able to undertake a thermal imaging survey is:

- The type and size of building.

- Floor plans and elevation drawings for the building.

- Any site-specific items to actions, i.e. attending site inductions and/or bringing specific ID such as passports, driving licence etc.

- The amount of time required to safely undertake the survey.

- The type of equipment required to undertake the inspection.

- The project location and subsequent travel time.

- The project deliverables – what needs to be included within the thermal survey report.

Please contact us for more information

Our team of thermographers are highly experienced in carrying out thermal imaging surveys and have many years’ experience in all aspects of engineering, construction, maintenance, management, and professional survey work.

Our thermal imaging equipment is the best and most accurate on the market, ensuring we pick up faults that other equipment may miss. Our reports are professionally presented and are clear, concise, and easy to follow. We endeavour to give our clients a first-class service every time.

If you would like to contact us for more information on our thermal imaging services, please contact us on 01525 303905 or email us at info@aptsoundtesting.co.uk. Alternatively if you would like more information on how to prepare for your thermal imaging survey, please visit the APT Sound Testing website or download our thermal imaging checklist