Detection of Air Leaks Using Thermal Imaging

Detection of Air Leaks Using Thermal Imaging and Air Tightness Testing

Air leaks through building envelopes lead to higher energy consumption and often places extra strain on the heating and ventilation systems. Air leaks can also lead to condensation which can cause a poor indoor climate for the occupiers of the building.

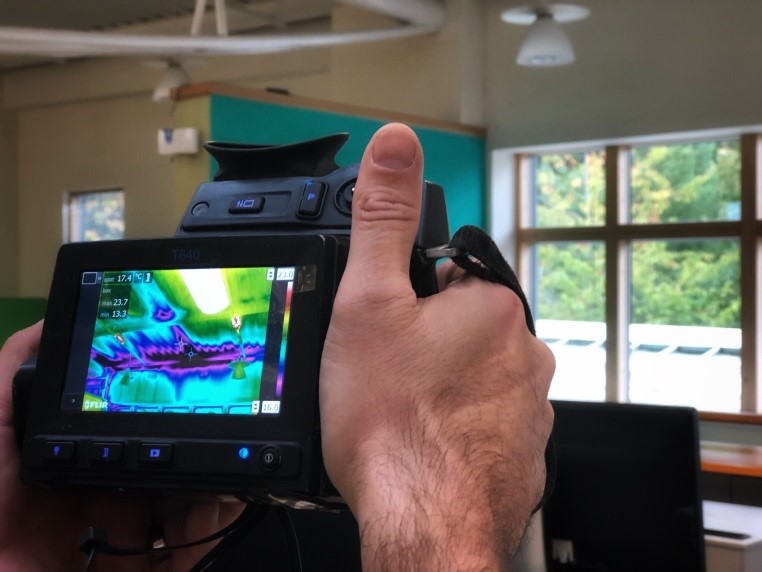

To detect air leaks through the building envelope using a thermal imaging camera a temperature difference and a pressure difference is needed. With a thermal imaging camera you detect the characteristic patterns that occur when cold air is coming through a leak in the building construction which runs along a surface and cools the surface down.

A thermal imaging inspection should always be undertaken on the side of the construction with negative pressure. Air leaks are often detected with the help of the air tightness pressurisation method often referred to as an air tightness test. When air tightness testing and thermal imaging survey inspections are used together they make a powerful combination for building fault diagnosis.

Set up an air tightness test and thermal imaging inspection

Small cracks and crevices can cause internal draft in the building. This is not only annoying for the occupants; it can also cause severe energy loss and higher ongoing costs. Building Air leakage can account for up to half of the energy consumed for heating purposes. By undertaking an air tightness test you can easily make the smallest cracks visible.

Using a Blower Door to help pressurise the building helps exaggerate air leaking through defects within the building shell which can easily be picked up during the thermal imaging inspection.

Our Blower Door systems include the following three components:

- A calibrated Retrotec door fan

- A compatible expandable a door panel system

- A Retrotec pressure gauge to measure fan flow and building pressure.

Our Blower Door fan is temporarily sealed into an exterior doorway using the corresponding door panel system. The fan is used to blow air into or out of the building, which creates a small pressure difference between inside and outside the building under test. Using our air tightness fan system we can either suck air out of the building or blow air into it, causing a pressure difference. In situations where the outside air is colder – which is often the case in the UK – the most common method is to suck air out of the building using the depressurisation method.

During the air tightness test we aim to attain a pressure difference of 50 Pascal between the inside of the building and outside air pressure. Due to this pressure difference the outside air will rush into the building through the cracks that are present in the building envelope (floor, walls and/or ceiling). The outside air will quickly cool down the location where an air leakage crack is present. This temperature difference will clearly show up in the thermal image as a cold spot or cold area, allowing our Thermal Imaging Engineer to accurately locate and map the air infiltration pathway within an easy to follow report.

We have extensive experience in conducting commercial building air tightness and thermal imaging surveys across the following types of buildings/businesses:

- Warehouses

- Factories

- Office Blocks

- Blocks of Flats

- Universities

- Schools

- Hospitals

- Railway Stations

If you require a BREEAM Thermal survey our professional and certified Level 2 Thermographer’s will carry out your thermographic Inspections for BREEAM compliance in accordance with all necessary standards and current regulations, all we need are a few details such as floor plans and elevation drawings and the building location to provide a quotation. We will also send across our informative Thermal Survey Checklist to help you prepare for the thermographic Inspection.

Contact APT Sound Testing for a free quotation for a thermographic inspection. All we need are a few details such an elevation drawings, floor plans and location to provide a quotation.

If you would like more information about the detection of air leaks using thermal imaging or BREEAM Thermographic Inspection Surveys, please contact us now at info@aptsoundtesting.co.uk or call us today on: 07775 623464.