Preparing for an Electrical Infrared Inspection

Preparing for an Electrical Infrared Inspection

When preparing for an electrical infrared inspection, several critical considerations must be taken into account. This guide will help explain how we, along with our clients, need to prepare for an electrical thermal imaging survey of their building.

Site Preparation

1. Select the Right Thermal Imaging Camera

The choice of thermal imaging camera is crucial for effective infrared inspections. We ensure that our infrared inspection cameras possess the necessary resolution and sensitivity required for electrical inspections. By exclusively using high-resolution and high-sensitivity cameras, we guarantee the capture of the best images and data during our inspections. This enables us to identify potential issues accurately and provide reliable diagnostics.

2. Identify the Correct Safety Gear

Safety is paramount in all our operations. Therefore, we always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and insulated clothing. This not only protects our team but also ensures that the inspection is conducted in a safe manner, adhering to all relevant safety standards and regulations.

3. Undertake a Detailed Inspection Plan

A thorough inspection plan is essential for a comprehensive thermal imaging survey. We outline the areas and components to be inspected, including electrical panels, switchgear, transformers, and wiring. This plan is agreed upon with our clients before we attend the site to ensure that all critical components are inspected and nothing is overlooked. This preparatory step ensures that the inspection is both efficient and thorough.

4. Thermal Imaging Checklist

We provide our clients with an electrical thermal imaging checklist to help them prepare for our site inspection visit. This checklist includes all the necessary steps and preparations they need to undertake to ensure that the inspection can proceed smoothly and without any interruptions. It also helps our clients understand the scope of the inspection and what to expect.

Infrared Inspection of Electrical Installations

1. Systematic Infrared Inspection

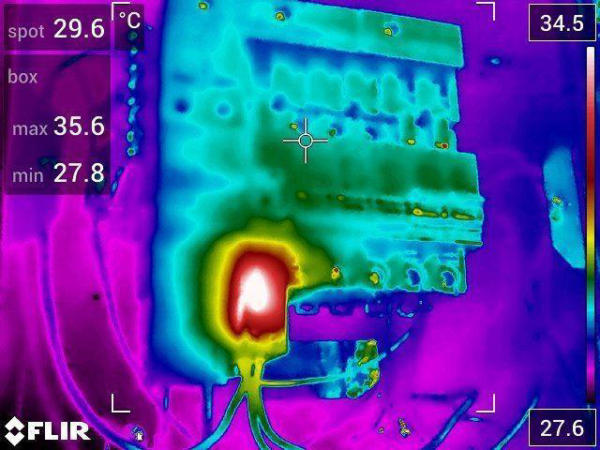

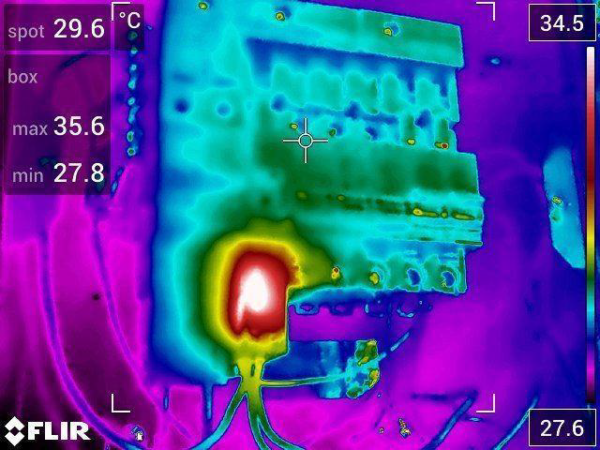

Our approach to infrared inspection is systematic and comprehensive. We perform thermal imaging inspections of all electrical components, including electrical outlets, switches, and service panels, to identify any anomalies or hot spots. By systematically covering all critical areas, we ensure that potential issues are detected early, preventing costly repairs or downtime in the future.

2. Document Findings

Accurate documentation is a crucial part of our inspection process. We record any anomalies, hot spots, or unexpected thermal patterns observed during the inspection. This documentation forms the basis of our inspection reports, providing clients with a detailed record of the condition of their electrical systems. It also helps in tracking the performance and maintenance needs of these systems over time.

Our Professional Infrared Inspection Service

We have conducted hundreds of infrared electrical surveys throughout London and the UK, building a reputation for reliability and accuracy. Our engineers are highly trained and certified, ensuring that our clients receive the best possible service. The key features of our thermal imaging service include:

1. Level 3 Thermographic Certification

Our engineers hold Level 3 thermographic certification, the highest level of qualification in the field. This certification demonstrates their expertise and ability to conduct advanced thermal imaging inspections and interpret the results accurately.

2. Level 3 Qualified Electrical Thermographers

In addition to their thermographic certification, our engineers are also Level 3 qualified electrical thermographers. This dual expertise ensures that they have a deep understanding of both thermal imaging and electrical systems, enabling them to provide comprehensive and accurate diagnostics.

3. Large Format FLIR Cameras with 45-Degree Lenses

We use state-of-the-art FLIR cameras equipped with 45-degree lenses. These cameras provide a wide field of view, allowing us to capture detailed thermal images of large areas and complex electrical installations. The high resolution and sensitivity of these cameras ensure that even the smallest anomalies are detected.

4. Detailed and Easy-to-Follow Inspection Reports

Our thermal imaging inspection reports are detailed yet easy to follow. They include all the findings from the inspection, with clear explanations and recommendations. These reports help our clients understand the condition of their electrical systems and make informed decisions about maintenance and repairs.

If you have any further questions regarding the above information, please don’t hesitate to contact APT at 01525 303905 or 07775 623464 or via email at info@aptsoundtesting.co.uk. For more information on how to prepare for an infrared electrical inspection, please visit our website.

By following these guidelines and working closely with our team, you can ensure that your electrical infrared inspection is thorough, accurate, and beneficial for the maintenance and safety of your building’s electrical systems.