Thermal Imaging Inspections to identify Building Faults

Thermal Imaging Inspections to identify Building Faults

Thermal imaging can quickly analyse working machinery, electrical systems and identify heat loss in building construction. Thermal imaging inspections is a quick and easy way for contractors and developers to save time and money and prevent accidents that could lead to property damage and even loss of life.

What Is Thermal Imaging?

Thermal imaging detects varying levels of heat based on the infrared waves emitted by objects. Professional thermal imaging cameras can see subtle differences in temperature to create a detailed image of hot and cold areas with accurate temperature measurements. Differences in temperature can be used to pinpoint potential problems in malfunctioning equipment and in systems that have been installed improperly. When used with our blower door systems it becomes an even more powerful tool for fault diagnosis for building envelopes.

What Industries Use Thermal Imaging?

The main benefit of thermal imaging is it doesn’t require equipment to be shut down to be inspected. The trained operator can quickly inspect and document faults and determine when repairs should be scheduled without shutting down your critical assets.

Safety is another reason that thermal cameras have become a regular tool for maintenance teams. Technicians do not have to be close to the machinery being tested as the photo can be taken from a distance, keeping techs safe while still acquiring the needed information.

Thermal Imaging for Building Inspections

Building inspections use thermal imaging to detect defects in the fabric of the building, i.e. the walls, roof, and floor. This can be items such as damaged or missing insulation, as well as damp and/or water leaks. Its worth noting that you can also gain extra BREEAM credits if you undertake a thermal imaging survey. One of the major ussies with building inspections is identifying water leaks that have not been revealed during other ‘more standard’ visual surveys. Determining if there is excessive moisture and finding the source of a leak through the normal inspection process may prove very difficult and costly as you may need to provide safe access such as scaffold for roof inspections etc.

Wet building materials will usually be colder than dry materials and a thermal camera can alert the thermographer as to where there may be problems. Wet insulation, framing, drywall, and masonry can be revealed, allowing stakeholders to make informed decisions as to the necessary repairs whilst saving on cost and program.

Thermal imaging for Industrial Maintenance

Many manufacturing companies operate 24 hours a day, so taking any critical equipment off-line to run any type of maintenance can be extremely costly. Ne quick and reliable way to inspect your critical assets is via thermal imaging. enhanced when thermal imaging is part of an asset inspection and condition-based maintenance program (CBM). Downtime and maintenance expenses can both be reduced with a CBM program since maintenance only occurs when it’s needed, rather than on a set schedule. Thermal imaging allows excessive heat in electrical, mechanical, and process equipment to be detected early in the failure curve. This minimizes the risk of a catastrophic failure, business interruption, and potentially dangerous conditions.

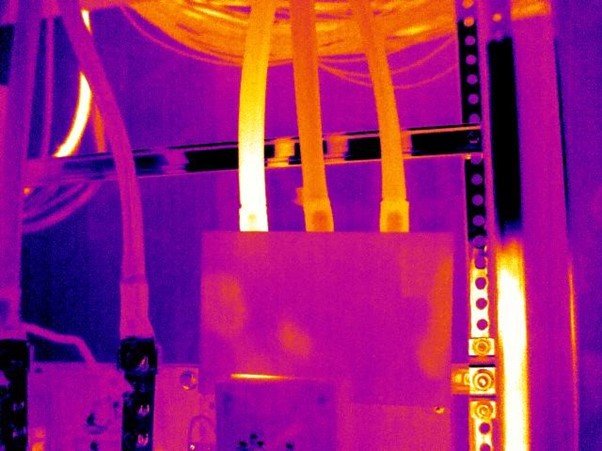

Thermal imaging for electrical utility inspections

Electrical distribution systems are one of the most important utilities in homes and businesses and support millions of users every day. Quickly locating potential failures in the electrical systems using thermal imaging is essential for providing constant service to customers. Main incoming, Distribution Boards, Transformers, circuit breakers and switches are common points in electrical systems that usually heat up before failure. Thermal cameras can quickly and safely detect hotspots, by measuring the temperature, allowing for engineers to schedule repairs before system failure occurs.

Thermal imaging for home inspections

Home inspectors must find problems that are difficult to see such as water leaks damp and moisture damage as well as accurately pinpoint leak leaks. Wet insulation, framing, and drywall can be quickly revealed, allowing home buyers to make informed decisions and a good investment prior to buying a property.

Thermal imaging for identifying air leakage in buildings

When used with a blower door fan, thermal imaging can be extremely accurate when identifying air leaks through the building envelope. This allows our clients to undertake targeted remedial sealing works to improve the air tightness of their building/s. By imprinting the air tightness, it also reduces draughts and lowers your energy usage, sometimes by up to 20%.

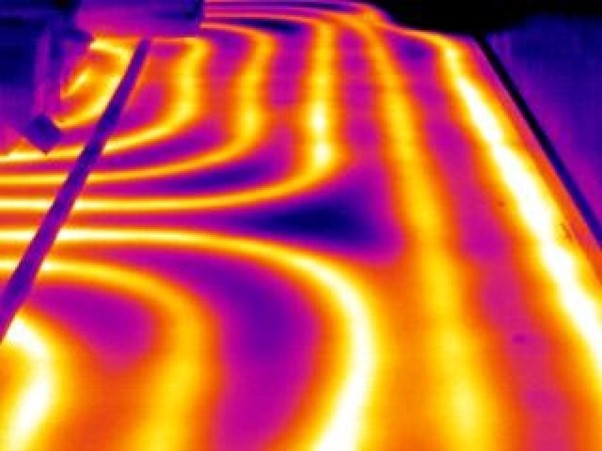

Thermal imaging for identifying leaks in underfloor heating

Thermal imaging is often used to diagnose problems with under floor heating systems. It’s can quickly pinpoint the leak, which often means the difference of carefully removing one tile to fix the problem, rather than tearing out an expensive tiled floored with the increased cost and damage this brings.

APT provide Level 3 thermal imaging inspections

APT Sound Testing is a leading provider of thermal imaging inspections across London and the UK. We provide Level 3 Thermographers, along with the latest high resolution thermal cameras and software to provide detailed reports to our valued clients. We offer thermal imaging services to Building Contractors, FM companies and utility and construction companies. Our team of industry professionals’ pride ourselves on offering a friendly professional service from start to finish.

Our thermal imaging inspection service includes:

- Level 3 certified field engineers

- The latest high resolution thermal imaging cameras

- Fully calibrated equipment

- The latest diagnostic software

- 20 years of experience in the thermography sector.

We can carry out on-site inspections and thermographic surveys on a one-off basis, such as a BREEAM building envelope survey, or as part of an ongoing maintenance program. Please speak to us if you’d like to learn more about this crucial service – and how we can help your project. If you would like more information on how to prepare for the thermal imaging survey please check out the following thermal imaging checklist

APT’s thermographic survey engineers can quickly identify imminent and future problems, allowing repairs to be carried out during scheduled maintenance. So, if you’re interested in thermographic surveys, on-site thermal inspections please let us know.

Please contact APT Sound Testing on 07775623464 or email us at info@aptsoundtesting.co.uk for more information.