What is a Floor Plenum Test?

What is a Floor Plenum Test?

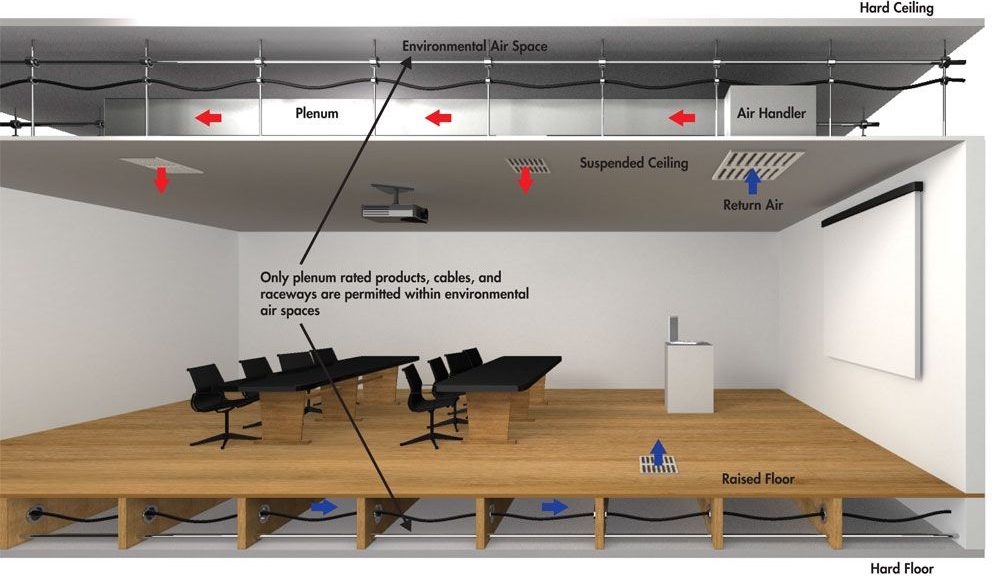

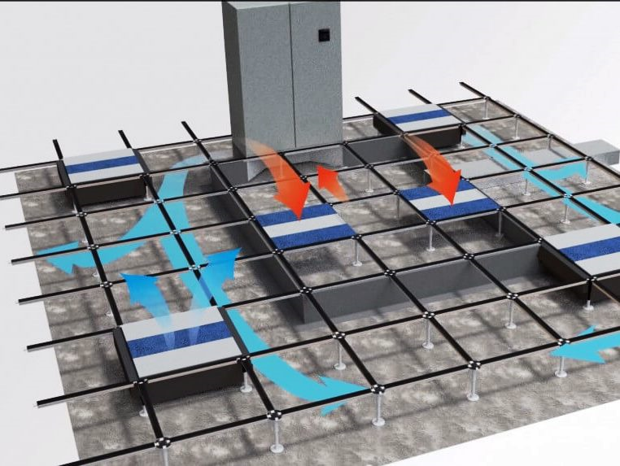

A floor plenum is a void between a building’s floor structure and a raised access floor. The floor plenum is used for distributing conditioned air to the spaces above.

It is important that conditioned air in a floor plenum flows into the occupied zone and does not leak into cavities, risers, stairwells, heating trenches or other adjacent zones. A properly sealed floor plenum will allow the floor grills and diffusers to fulfil their primary role of delivering air at the correct flow rate. As a result, the airtightness of floor plenums (or lack of) can be a serious energy efficiency issue and is essential for the whole air conditioning system to work.

Testing procedure BG65 / 2016, addresses these issues and places upper limits on the air leakage of floor plenums. Distinctions are made between air leakage to adjacent spaces – normally referred to as plenum leakage, and uncontrolled air leakage into conditioned zones – normally referred to as raised access floor leakage.

How is a floor plenum test carried out?

In brief, we remove a box a temporary a tile is removed from the plenum and our fan housing is installed directly above the opening. A fan is then installed into the box and this is all sealed against the floor. Any air handling ducts serving the test zone need to be turned off, isolated and temporarily sealed, stopping the passage of air to outside of the test zone via duct-work. Thereafter another tile is removed and a mock floor tile with a drill hole for the high pressure tube is installed in its place. After the equipment is set up a series of tests is undertake and the readings recorded and then checked against the floor plenum air tightness specification.

If the plenum test fails, you’re APT plenum test engineer will carry out a smoke test to look for air leakage paths. If you have floor or ceiling plenums in your building you need to be aware that a staggering 70-80% fail their first air tightness test. APT Sound Testing has years of experience of raised access floor plenum testing and can work with you to ensure you pass your floor plenum air test at the first attempt.

We can ensure that an onsite air test site audit is arranged as soon as the floor is in place; we can then undertake an initial floor plenum air test and smoke survey to check the air leakage result and check for air leakage paths within the plenum envelope. Once we have assessed the air leakage paths we can then supply a smoke survey report for your sealing contractors to use as reference to ensure your plenums are adequately sealed.

The most common air leakage paths within floor plenum construction

In order to create an effective airtight floor plenum and achieve a successful floor plenum air test, all mechanical and electrical penetrations and perimeter joints must be properly sealed. An evaluation of the following areas/components that can typically create Inefficiencies should be undertaken during the early design phases:

- All service penetrations through the access floor, walls and subfloor including:

- Cable bundles and cable trays

- Pipes

- Fire/plenum barriers

- Cable trunking – must be internally sealed within the void

- Masonry work – incomplete or poorly jointed masonry walls will result in greater air leakage. All masonry joints must be filled and masonry paint applied as a finish.

- Risers need to be properly sealed throughout all plenums/ducting need to be sealed.

- Plasterboard on studs at board edges and the ends below the raised floor level need to be sealed.

- Gaps between compartment barriers, top of raised access floor and sub floor respectively need to be sealed.

- Gaps between any curtain walling/glazing need to be sealed.

What happens if I fail my Floor Plenum Test?

A large number of floor plenums (70-80%) fail the initial air tightness test so don’t panic!

If we undertake the floor plenum test and it fails UKAS accredited test engineers will undertake a targeted smoke survey to highlight the main air leakage paths. We will then issue a detailed smoke survey report for your contactors to reference during the remedial sealing works. This will help us the remedial sealing works at they can quickly target the main air leakage paths within the floor plenum construction. We can also undertake thermal imaging surveys to pinpoint the main air leakage paths on the day of the plenum testing.

We also allow for the option of visiting site during the sealing works to ensure your contractors are adequately sealing the plenum prior to the second air tightness test. If you would like more information in regards to the most common air leakage paths visit our Plenum Testing page or call us on 01525 303905. Supporting document BG65 / 2016 also contains lots of information on how to design, constructing and test floor plenums.

Alternatively, for more information on all our services please visit our website at: www.aptsoundtesting.co.uk