Improving Ceiling Soundproofing to Reduce Noise

Improving Ceiling Soundproofing to Reduce Noise from Above

In most cases, the traditional upper floor structure, consisting of timber joists covered by chipboard boarding/or floorboard and a thin layer of plasterboard ceiling, offers little sound insulation and resistance. By itself, it won’t achieve the minimum standard requirement of the Building Regulations Part E of 45dB for new build or 43dB for conversion dwellings.

To improve the soundproofing in your ceiling partition, there are many things to consider such as: Improving the mass, isolation, absorption, resilience, and stiffness.

To try and reduce the ceiling noise in your flat below, you can add insulation a good-quality acoustic insulation between the joists – 100mm of mineral wool of at least 45kg/m3 density, then add resilient bars and 2 layers of 15mm plasterboard.

Unlike walls, floors can transmit impact sound as well as airborne sound and, in our experience, having helped with hundreds of clients suffering noise issues, impact sound is often more annoying than airborne noise transmission.

One of the easiest ways to deal with impact sound is by installing an acoustic resilient membrane. For instance, a resilient layer can be installed on the subbase flooring (chipboard) prior to the installation of the final floor finishes. The membrane is very simple to lay and comes with its own glue to bond it to the sub-base flooring. The final flooring – such as engineered wood, simply floats on top of the membrane with the tongued joints glued on each board – no other fixing such as screws etc. are required. In fact, screwing or nailing down the final floor finish would actually create a sound path through the floor construction.

Acoustic resilient membranes are usually between 4-6mm; however, you can get a more expensive option that also deals with airborne sound which are 10-15mm depending on the material and specification. In most cases the acoustic membrane is rubber-based; however, the higher specification can be a composite material which is foam, rubber, and even cement board. When installing the membrane its often supplied with a propriety noise flanking strip which is installed between the skirting boards and the floor boarding, this helps to avoid direct contact between the skirting board and the floor boarding.

You can also help to improve the soundproofing, by installing a high-mass mineral wool batt. The depth of the wool should be 100mm and at least 45kg/m3. This is quite easy to install, and the batt should be cut tight against the joists with no gaps.

It is also worth checking that there isn’t too much movement or deflection in the floor joists – if you hear a loud booming sound, as well as the tapping of footfall fall noise, it maybe your joists are moving above. In this case, it would be best to install extra noggins between the joist to add stiffness to the construction.

To help improve the airborne sound, install resilient bars below the joists running the opposite way to the joists and below the bars install 2 x 15mm layers of sound board. All boards must be properly lapped, and the perimeter joints filled with acoustic mastic. The plasterboard should be taped and jointed and receive a skim finish.

If you can afford the extra headroom, a secondary suspended ceiling formed beneath the floor joists is ideal, as this will be a totally independent construction. The ceiling can be supported by new timber joists that span from wall to wall, completely separate to the floor above. A minimum gap of 25mm is advisable between the bottom of the joists and the top of the new timber joists. Two layers of 15mm sound-quality plasterboard can be installed to the bottom of the new joists and a 50mm acoustic batt (min density 45kg/m3) fitted above the plasterboard.

It is worth noting that two layers of plasterboard can be 26kg/m2, so you should always check the joists’ size and spans with an engineer prior to the installation. To finish the boards always use acoustic sealant around the perimeter edges.

Approved Document E states that the minimum sound insulation values for New Building Properties is an airborne resistance of 45dB or more and impact 62dB or less. For conversion properties, it’s an airborne resistance of 43dB or more and impact 64dB or less. If you don’t want to suffer from noise issues, you should be achieving these targets as a minimum. Please note when trying to improve upon dB ratings for both types of noise, the higher the Airborne noise figure the better and the lower the impact noise the better).

We can help with acoustic design for your ceiling

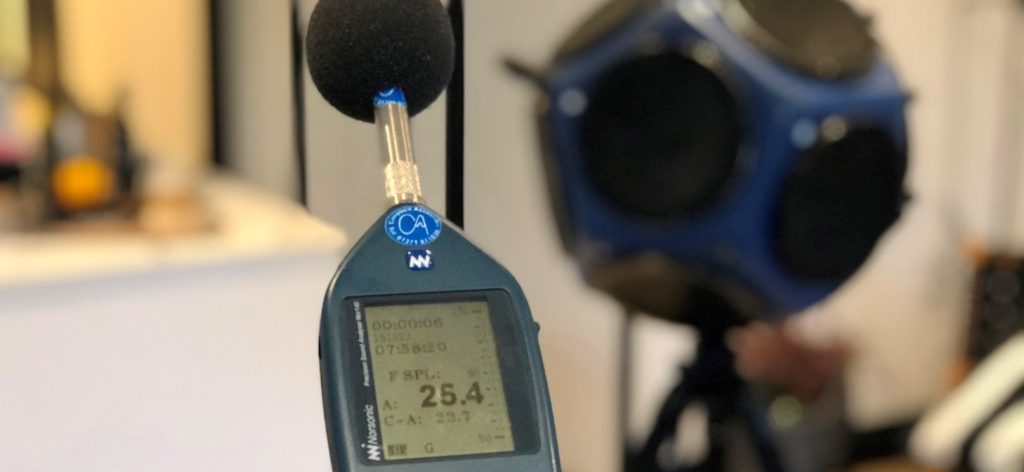

It can be very time-consuming trying to identify the cause of excess noise through ceilings. To reduce the risk of acoustic issues its always best to hire an experienced acoustic consultant. We are a UKAS accredited company, so you can be sure of a friendly and professional service providing a ‘one stop’ solution for all your acoustic requirements. We also undertake sound testing for lease condition compliance, if you are changing the floor finish in your apartment and you need help with the acoustics please let us know.

If you would like more information in regards to sound testing service and/or acoustic design services in London, please contact us on 01525 303905 or info@aptsoundtesting.co.uk, for more information please visit our website at www.aptsoundtesting.co.uk or download our sound test checklist or visit our new sound testing blog.