Understanding BREEAM: Advancing Sustainability in the Built Environment

The importance of sustainable development has become paramount. As we strive to create a greener and more environmentally responsible future, a crucial aspect of this endeavor involves constructing and maintaining buildings that are energy-efficient, environmentally friendly, and socially responsible. This is where BREEAM comes into play.

What is BREEAM?

BREEAM, which stands for Building Research Establishment Environmental Assessment Method, is one of the world’s leading sustainability assessment methods for buildings. It was developed by the Building Research Establishment (BRE) in the United Kingdom back in 1990 and has since become an internationally recognized standard for evaluating a building’s environmental performance.

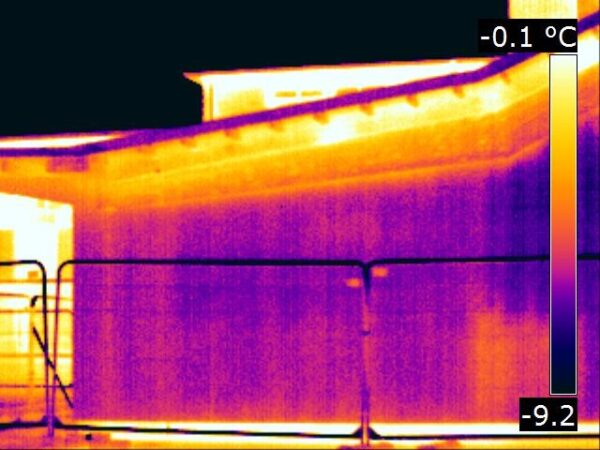

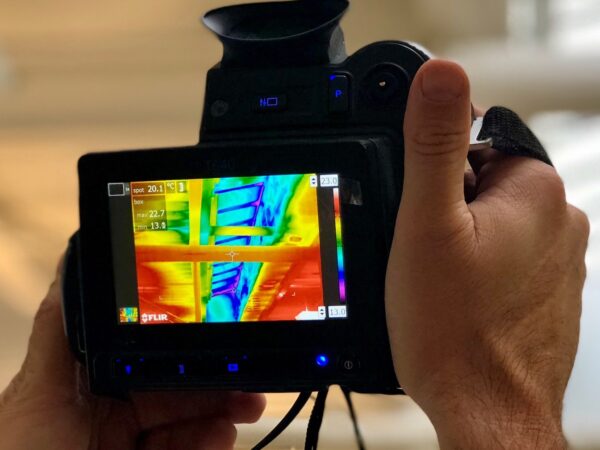

The main objective of BREEAM is to measure, evaluate, and certify the sustainability credentials of new and existing buildings across various criteria. These criteria encompass a wide range of factors, such as energy usage, water efficiency, waste management, indoor environmental quality, ecological impact, and social aspects. By rigorously assessing these elements, BREEAM helps stakeholders identify areas for improvement and implement sustainable practices to enhance a building’s overall performance.

Why is BREEAM important?

Environmental Benefits: BREEAM promotes environmentally responsible construction and operation practices, leading to reduced greenhouse gas emissions, lower energy consumption, and a smaller ecological footprint. By encouraging sustainable building techniques, it contributes to mitigating the impact of climate change and preserving natural resources.

Economic Advantages: Beyond its environmental impact, BREEAM delivers tangible economic benefits to property owners and occupants. Sustainable buildings often exhibit lower operating costs, improved energy efficiency, and increased asset value, making them more appealing to potential investors and tenants.

Health and Well-being: BREEAM takes into account factors that impact human health and well-being, such as indoor air quality, natural lighting, and acoustic comfort. By promoting healthier indoor environments, occupants of BREEAM-certified buildings may experience improved productivity, reduced sick days, and enhanced overall well-being.

Future-Proofing: With the growing emphasis on sustainability and environmental responsibility, BREEAM certification future-proofs buildings by ensuring they meet and adapt to evolving green building standards. This ensures that buildings remain relevant, competitive, and resilient in an ever-changing global landscape.

Global Recognition: BREEAM’s international recognition makes it a valuable tool for architects, developers, and investors working on projects worldwide. The certification’s credibility helps attract potential partners and funding, fostering collaborations that drive sustainable development on a global scale.

Policy Compliance: In many regions, BREEAM certification is tied to local building regulations and planning policies. Achieving BREEAM certification ensures compliance with these requirements, making the permitting process smoother and reducing the risk of non-compliance penalties.

BREEAM plays a pivotal role in advancing sustainability in the built environment. By assessing and certifying buildings based on comprehensive environmental, social, and economic criteria, BREEAM promotes responsible construction practices that benefit our planet, our economies, and the health and well-being of occupants.

Embracing BREEAM and its principles is a significant step toward creating a more sustainable and resilient future for generations to come.

Here at APT Sound Testing, we have been providing indoor air quality services such as post-construction air quality testing and indoor air monitoring for a number of years. We have assisted many customers in gaining their BREEAM and other compliance credits through our air quality plan and BREEAM air quality testing services.

Call us on 01525 303905 or email us on info@aptsoundtesting.co.uk about our services. We are here to help! Alternatively, please visit our contact page here.