A Thermographic Survey ~ Transform Your Property

Every home or building leaks energy, it’s just a matter of how much. In the UK, where energy prices continue to rise and the push toward net zero targets intensifies, understanding where your property is losing heat is more critical than ever. That’s where a thermographic survey, also known as a thermal imaging survey, comes in.

This advanced, non-invasive technique can uncover the hidden issues costing you money and comfort every single year, without tearing open walls or ceilings. Whether you’re a homeowner, landlord, developer, or business owner, a professional thermographic survey could be the key to unlocking your building’s full energy-saving potential.

What Is a Thermographic Survey?

A thermographic survey uses infrared cameras to detect and visualise heat patterns within a building. The resulting images, known as thermograms, make invisible problems instantly visible: areas where heat escapes, insulation is missing or poorly installed, air is leaking, or damp spots are forming.

This technology works by measuring temperature variations on surfaces and translating them into colour-coded images. Hot areas show up in warmer colours (like red or yellow), while colder areas appear in shades of blue or purple. The beauty of this method? It allows for fast, accurate assessment with no damage or disruption to your property.

Why Thermographic Surveys Matter in the UK

The UK housing stock is among the least energy-efficient in Europe. It’s estimated that around 26% of the country’s total energy consumption comes from domestic buildings, with 80% of that going directly into heating and hot water.

Despite this massive energy use, many homes continue to suffer from:

- Poor insulation

- Draughty windows and doors

- Leaky roofs and walls

- Unnoticed construction flaws

Even new-builds or recently renovated properties can fall short due to hidden gaps in workmanship or insulation installation. A thermal imaging survey is one of the fastest, most accurate ways to pinpoint these issues and create a roadmap for improvement.

Top Benefits of a Professional Thermographic Survey

Investing in a thermographic survey is about more than just diagnostics—it’s about actionable improvements that pay off. Here’s what you stand to gain:

1. Lower Energy Bills

By identifying and fixing draughts, thermal bridges, or insulation gaps, you reduce the amount of heat your building loses—cutting heating costs significantly.

2. Increased Comfort

No one likes cold spots, chilly corners, or rooms that never quite feel warm enough. Thermal imaging helps you eliminate these uneven temperature zones for a cosier, more comfortable indoor environment.

3. Early Damp and Mould Detection

Cold areas are prone to condensation, which can lead to mould and long-term structural issues. Thermographic surveys catch these problems before they become visible, protecting your health and your home.

4. Insulation Validation

Whether you’ve just installed new insulation or want to check the effectiveness of older material, a thermal imaging survey verifies whether it’s doing its job—saving you from wasted investments.

5. Sustainability and Compliance

From BREEAM standards to future government mandates on energy efficiency, thermal imaging helps you stay compliant and demonstrate climate responsibility. It also adds value when selling or renting your property.

What to Expect During a Thermographic Survey

If you’ve never booked one before, here’s how the process typically works:

✅ Tailored Consultation

We begin with a brief discussion about your property type, energy concerns, and goals. This helps us customise the survey to your specific needs.

✅ Best Timing

Thermal surveys are most effective in colder months or during times with a strong indoor-outdoor temperature difference—early morning or evening is ideal.

✅ Comprehensive Assessment

Our certified thermographers will scan both interior and exterior surfaces, using high-resolution infrared cameras to identify problem areas across walls, roofs, doors, windows, and floors.

✅ Professional Reporting

Within a few days, you’ll receive a detailed, illustrated report showing exactly where your property is losing energy—complete with explanations and recommendations for improvement.

✅ Expert Advice

Our team will walk you through the findings and help prioritise the most cost-effective and impactful upgrades.

Who Should Consider a Thermal Imaging Survey?

A thermographic survey is suitable for a wide range of properties and owners, including:

- Homeowners looking to reduce bills and enjoy a warmer home

- Landlords and property managers aiming to boost EPC ratings and tenant comfort

- Buyers wanting peace of mind before a purchase

- Architects and builders needing verification for new construction

- Businesses, schools, and organisations working toward net zero goals

Whether you’re retrofitting an older home, quality-checking a new build, or developing an energy strategy for a commercial building, thermal imaging gives you the clear data needed to act.

Why Choose Us?

Not all thermographic surveys are created equal. With us, you’re getting industry-leading expertise backed by decades of hands-on experience. Here’s what sets our service apart:

- Certified Thermographers: Our team is fully trained and certified to deliver accurate results.

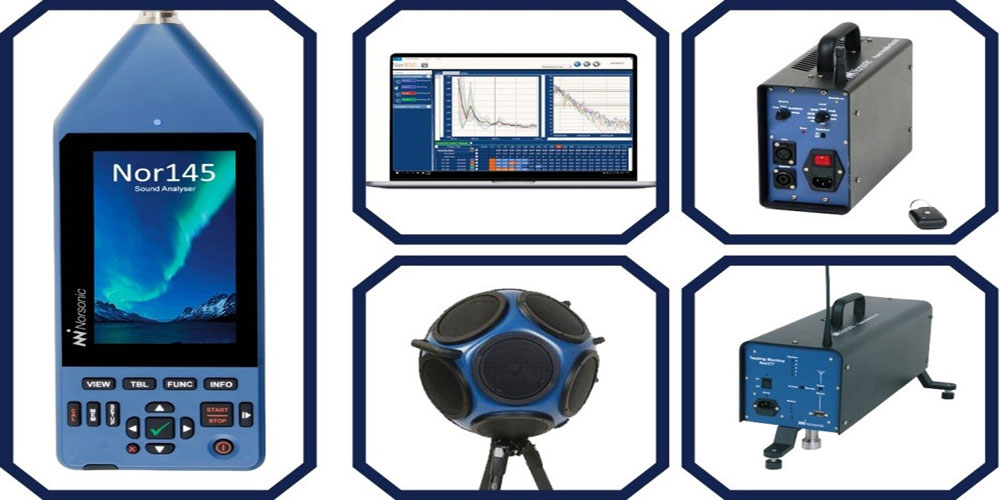

- High-Tech Equipment: We use top-of-the-line infrared cameras and support tools like blower door and smoke testing for enhanced diagnostics.

- Fast Turnaround: Most surveys take 1–2 hours and reports are delivered within 5–10 working days.

- Competitive Pricing: Transparent quotes with no hidden fees.

- Regulatory Support: Assistance with BREEAM, EPC improvements, and building compliance.

FAQs

How long does the survey take?

Surveys usually last between 1 to 2 hours, depending on the size and complexity of the building.

Do I need to prepare my home?

Yes, but it’s simple. We’ll give you clear guidance, such as heating your home a few hours in advance and keeping doors and windows shut during the survey.

How soon will I get the report?

Your illustrated thermographic report is typically delivered within 5–10 working days.

Take the First Step Toward a Warmer, Greener Property

Don’t wait for another winter of high bills and cold rooms. A thermographic survey offers a fast, affordable way to make your property more efficient, comfortable, and future-ready.

Contact our expert team today to get a free consultation or instant quote. Most surveys are completed in under two hours—and the energy savings could last a lifetime.

About the Expert: Darren Helliwell

Darren Helliwell is a seasoned building performance specialist with over 25 years of experience in thermographic surveys, blower door testing, and airtightness consulting. He has worked on prestigious projects like Harrods, Battersea Power Station, and the Imperial War Museum, helping teams enhance building performance and energy efficiency.

Using advanced infrared cameras and complementary testing tools, Darren’s team identifies air leakage, insulation defects, and thermal bridging in both new and existing buildings. His mission? To empower homeowners, architects, and contractors with the insights they need to build better, healthier, and more efficient spaces.

👉 Connect on LinkedIn

📧 info@aptsoundtesting.co.uk

🌐 APT Building Thermography ReportsEvery home or building leaks energy—it’s just a matter of how much. In the UK, where energy prices continue to rise and the push toward net zero targets intensifies, understanding where your property is losing heat is more critical than ever. That’s where a thermographic survey, also known as a thermal imaging survey, comes in.

This advanced, non-invasive technique can uncover the hidden issues costing you money and comfort every single year—without tearing open walls or ceilings. Whether you’re a homeowner, landlord, developer, or business owner, a professional thermographic survey could be the key to unlocking your building’s full energy-saving potential.

What Is a Thermographic Survey?

A thermographic survey uses infrared cameras to detect and visualise heat patterns within a building. The resulting images, known as thermograms, make invisible problems instantly visible: areas where heat escapes, insulation is missing or poorly installed, air is leaking, or damp spots are forming.

This technology works by measuring temperature variations on surfaces and translating them into colour-coded images. Hot areas show up in warmer colours (like red or yellow), while colder areas appear in shades of blue or purple. The beauty of this method? It allows for fast, accurate assessment with no damage or disruption to your property.

Why Thermographic Surveys Matter in the UK

The UK housing stock is among the least energy-efficient in Europe. It’s estimated that around 26% of the country’s total energy consumption comes from domestic buildings, with 80% of that going directly into heating and hot water.

Despite this massive energy use, many homes continue to suffer from:

- Poor insulation

- Draughty windows and doors

- Leaky roofs and walls

- Unnoticed construction flaws

Even new-builds or recently renovated properties can fall short due to hidden gaps in workmanship or insulation installation. A thermal imaging survey is one of the fastest, most accurate ways to pinpoint these issues and create a roadmap for improvement.

Top Benefits of a Professional Thermographic Survey

Investing in a thermographic survey is about more than just diagnostics—it’s about actionable improvements that pay off. Here’s what you stand to gain:

1. Lower Energy Bills

By identifying and fixing draughts, thermal bridges, or insulation gaps, you reduce the amount of heat your building loses—cutting heating costs significantly.

2. Increased Comfort

No one likes cold spots, chilly corners, or rooms that never quite feel warm enough. Thermal imaging helps you eliminate these uneven temperature zones for a cosier, more comfortable indoor environment.

3. Early Damp and Mould Detection

Cold areas are prone to condensation, which can lead to mould and long-term structural issues. Thermographic surveys catch these problems before they become visible, protecting your health and your home.

4. Insulation Validation

Whether you’ve just installed new insulation or want to check the effectiveness of older material, a thermal imaging survey verifies whether it’s doing its job—saving you from wasted investments.

5. Sustainability and Compliance

From BREEAM standards to future government mandates on energy efficiency, thermal imaging helps you stay compliant and demonstrate climate responsibility. It also adds value when selling or renting your property.

What to Expect During a Thermographic Survey

If you’ve never booked one before, here’s how the process typically works:

✅ Tailored Consultation

We begin with a brief discussion about your property type, energy concerns, and goals. This helps us customise the survey to your specific needs.

✅ Best Timing

Thermal surveys are most effective in colder months or during times with a strong indoor-outdoor temperature difference—early morning or evening is ideal.

✅ Comprehensive Assessment

Our certified thermographers will scan both interior and exterior surfaces, using high-resolution infrared cameras to identify problem areas across walls, roofs, doors, windows, and floors.

✅ Professional Reporting

Within a few days, you’ll receive a detailed, illustrated report showing exactly where your property is losing energy—complete with explanations and recommendations for improvement.

✅ Expert Advice

Our team will walk you through the findings and help prioritise the most cost-effective and impactful upgrades.

Who Should Consider a Thermal Imaging Survey?

A thermographic survey is suitable for a wide range of properties and owners, including:

- Homeowners looking to reduce bills and enjoy a warmer home

- Landlords and property managers aiming to boost EPC ratings and tenant comfort

- Buyers wanting peace of mind before a purchase

- Architects and builders needing verification for new construction

- Businesses, schools, and organisations working toward net zero goals

Whether you’re retrofitting an older home, quality-checking a new build, or developing an energy strategy for a commercial building, thermal imaging gives you the clear data needed to act.

Why Choose Us?

Not all thermographic surveys are created equal. With us, you’re getting industry-leading expertise backed by decades of hands-on experience. Here’s what sets our service apart:

- Certified Thermographers: Our team is fully trained and certified to deliver accurate results.

- High-Tech Equipment: We use top-of-the-line infrared cameras and support tools like blower door and smoke testing for enhanced diagnostics.

- Fast Turnaround: Most surveys take 1–2 hours and reports are delivered within 5–10 working days.

- Competitive Pricing: Transparent quotes with no hidden fees.

- Regulatory Support: Assistance with BREEAM, EPC improvements, and building compliance.

FAQs

How long does the survey take?

Surveys usually last between 1 to 2 hours, depending on the size and complexity of the building.

Do I need to prepare my home?

Yes, but it’s simple. We’ll give you clear guidance, such as heating your home a few hours in advance and keeping doors and windows shut during the survey.

How soon will I get the report?

Your illustrated thermographic report is typically delivered within 5–10 working days.

Take the First Step Toward a Warmer, Greener Property

Don’t wait for another winter of high bills and cold rooms. A thermographic survey offers a fast, affordable way to make your property more efficient, comfortable, and future-ready.

Contact our expert team today to get a free consultation or instant quote. Most surveys are completed in under two hours—and the energy savings could last a lifetime.

About the Expert: Darren Helliwell

Darren Helliwell is a seasoned building performance specialist with over 25 years of experience in thermographic surveys, blower door testing, and airtightness consulting. He has worked on prestigious projects like Harrods, Battersea Power Station, and the Imperial War Museum, helping teams enhance building performance and energy efficiency.

Using advanced infrared cameras and complementary testing tools, Darren’s team identifies air leakage, insulation defects, and thermal bridging in both new and existing buildings. His mission? To empower homeowners, architects, and contractors with the insights they need to build better, healthier, and more efficient spaces.

👉 Connect on LinkedIn

📧 info@aptsoundtesting.co.uk

🌐 APT Building Thermography Reports

Why a Thermographic Survey Could Transform Your Property

Every home or building leaks energy—it’s just a matter of how much. In the UK, where energy prices continue to rise and the push toward net zero targets intensifies, understanding where your property is losing heat is more critical than ever. That’s where a thermographic survey, also known as a thermal imaging survey, comes in.

This advanced, non-invasive technique can uncover the hidden issues costing you money and comfort every single year—without tearing open walls or ceilings. Whether you’re a homeowner, landlord, developer, or business owner, a professional thermographic survey could be the key to unlocking your building’s full energy-saving potential.

What Is a Thermographic Survey?

A thermographic survey uses infrared cameras to detect and visualise heat patterns within a building. The resulting images, known as thermograms, make invisible problems instantly visible: areas where heat escapes, insulation is missing or poorly installed, air is leaking, or damp spots are forming.

This technology works by measuring temperature variations on surfaces and translating them into colour-coded images. Hot areas show up in warmer colours (like red or yellow), while colder areas appear in shades of blue or purple. The beauty of this method? It allows for fast, accurate assessment with no damage or disruption to your property.

Why Thermographic Surveys Matter in the UK

The UK housing stock is among the least energy-efficient in Europe. It’s estimated that around 26% of the country’s total energy consumption comes from domestic buildings, with 80% of that going directly into heating and hot water.

Despite this massive energy use, many homes continue to suffer from:

- Poor insulation

- Draughty windows and doors

- Leaky roofs and walls

- Unnoticed construction flaws

Even new-builds or recently renovated properties can fall short due to hidden gaps in workmanship or insulation installation. A thermal imaging survey is one of the fastest, most accurate ways to pinpoint these issues and create a roadmap for improvement.

Top Benefits of a Professional Thermographic Survey

Investing in a thermographic survey is about more than just diagnostics—it’s about actionable improvements that pay off. Here’s what you stand to gain:

1. Lower Energy Bills

By identifying and fixing draughts, thermal bridges, or insulation gaps, you reduce the amount of heat your building loses—cutting heating costs significantly.

2. Increased Comfort

No one likes cold spots, chilly corners, or rooms that never quite feel warm enough. Thermal imaging helps you eliminate these uneven temperature zones for a cosier, more comfortable indoor environment.

3. Early Damp and Mould Detection

Cold areas are prone to condensation, which can lead to mould and long-term structural issues. Thermographic surveys catch these problems before they become visible, protecting your health and your home.

4. Insulation Validation

Whether you’ve just installed new insulation or want to check the effectiveness of older material, a thermal imaging survey verifies whether it’s doing its job—saving you from wasted investments.

5. Sustainability and Compliance

From BREEAM standards to future government mandates on energy efficiency, thermal imaging helps you stay compliant and demonstrate climate responsibility. It also adds value when selling or renting your property.

What to Expect During a Thermographic Survey

If you’ve never booked one before, here’s how the process typically works:

✅ Tailored Consultation

We begin with a brief discussion about your property type, energy concerns, and goals. This helps us customise the survey to your specific needs.

✅ Best Timing

Thermal surveys are most effective in colder months or during times with a strong indoor-outdoor temperature difference—early morning or evening is ideal.

✅ Comprehensive Assessment

Our certified thermographers will scan both interior and exterior surfaces, using high-resolution infrared cameras to identify problem areas across walls, roofs, doors, windows, and floors.

✅ Professional Reporting

Within a few days, you’ll receive a detailed, illustrated report showing exactly where your property is losing energy—complete with explanations and recommendations for improvement.

✅ Expert Advice

Our team will walk you through the findings and help prioritise the most cost-effective and impactful upgrades.

Who Should Consider a Thermal Imaging Survey?

A thermographic survey is suitable for a wide range of properties and owners, including:

- Homeowners looking to reduce bills and enjoy a warmer home

- Landlords and property managers aiming to boost EPC ratings and tenant comfort

- Buyers wanting peace of mind before a purchase

- Architects and builders needing verification for new construction

- Businesses, schools, and organisations working toward net zero goals

Whether you’re retrofitting an older home, quality-checking a new build, or developing an energy strategy for a commercial building, thermal imaging gives you the clear data needed to act.

Why Choose Us?

Not all thermographic surveys are created equal. With us, you’re getting industry-leading expertise backed by decades of hands-on experience. Here’s what sets our service apart:

- Certified Thermographers: Our team is fully trained and certified to deliver accurate results.

- High-Tech Equipment: We use top-of-the-line infrared cameras and support tools like blower door and smoke testing for enhanced diagnostics.

- Fast Turnaround: Most surveys take 1–2 hours and reports are delivered within 5–10 working days.

- Competitive Pricing: Transparent quotes with no hidden fees.

- Regulatory Support: Assistance with BREEAM, EPC improvements, and building compliance.

FAQs

How long does the survey take?

Surveys usually last between 1 to 2 hours, depending on the size and complexity of the building.

Do I need to prepare my home?

Yes, but it’s simple. We’ll give you clear guidance, such as heating your home a few hours in advance and keeping doors and windows shut during the survey.

How soon will I get the report?

Your illustrated thermographic report is typically delivered within 5–10 working days.

Take the First Step Toward a Warmer, Greener Property

Don’t wait for another winter of high bills and cold rooms. A thermographic survey offers a fast, affordable way to make your property more efficient, comfortable, and future-ready.

Contact our expert team today to get a free consultation or instant quote. Most surveys are completed in under two hours—and the energy savings could last a lifetime.

About the Expert: Darren Helliwell

Darren Helliwell is a seasoned building performance specialist with over 25 years of experience in thermographic surveys, blower door testing, and airtightness consulting. He has worked on prestigious projects like Harrods, Battersea Power Station, and the Imperial War Museum, helping teams enhance building performance and energy efficiency.

Using advanced infrared cameras and complementary testing tools, Darren’s team identifies air leakage, insulation defects, and thermal bridging in both new and existing buildings. His mission? To empower homeowners, architects, and contractors with the insights they need to build better, healthier, and more efficient spaces.

👉 Connect on LinkedIn

📧 info@aptsoundtesting.co.uk

🌐 APT Building Thermography Reports