Thermal Imaging Inspection

How Much Does a Thermal Imaging Inspection Cost?

We often get asked ‘what’s the cost of a thermal survey’. It depends on numerous factors, such as the size and amount buildings you need to be surveyed, the project location, and the detail required for the thermal survey report.

The Thermal Imaging Inspection

This is a very common question clients ask us and it has a simple answer: it depends on numerous factors. When we sit down to work out our fee proposal for a Thermal imaging inspection, we ask the client a number of questions:

- The type and size of building.

- The amount of preparation required?

- The amount of time required to safely undertake the survey.

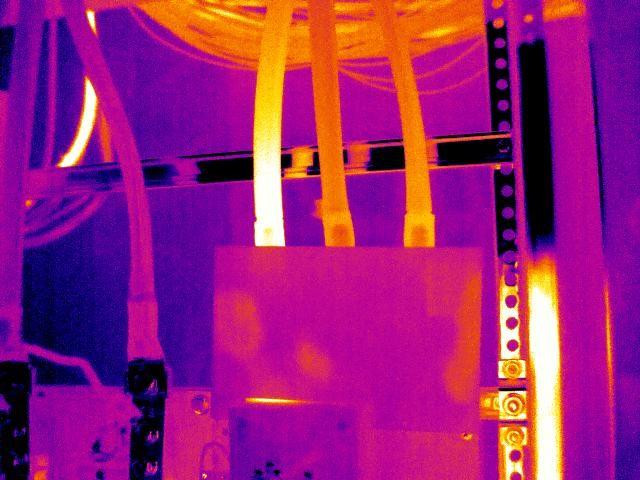

- The type of equipment required to undertake the inspection.

- The project location and subsequent travel costs/time.

- The required deliverables – what needs to be included within the thermal survey report.

- The amount of health and safety requirements i.e., some sites ask for 4-hour safety induction

So, taking the above into account we can offer a basic electrical thermal survey to a couple of distribution boards for £495 plus Vat, right up to the huge industrial areas, that may require multiple visits that may be in excess of £10,000 plus Vat, and of course everything in between. In all instances it’s best to call us so we gain a more accurate overview of our project and quoted; accordingly, so please contact us to discuss your project (along with any site-specific issues) and obtain a quote.

Is your thermal imaging company adequately trained?

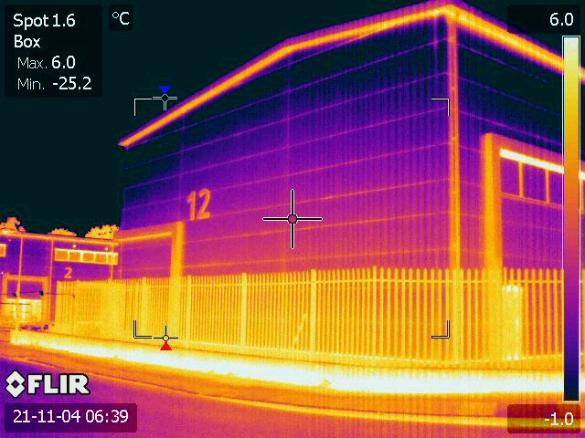

When you are employing a thermographer, you should check to see that they incorporate the high specifications possible for their inspections. Are they certified to Level 3 and do they use large format FLIR thermal imaging cameras, anything less and you may not get the thermal imaging report you need to comply with BREEAM.

Their specification should include:

- Level 3 thermographic certification

- Level 3 qualified thermographers

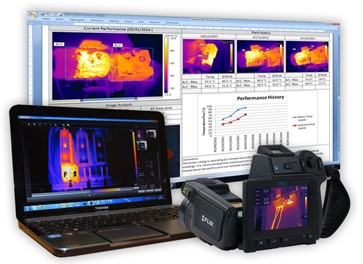

- Large format FLIR cameras with 45-degree lenses

The importance of clear and concise thermographic reports

We spend such a large amount of time on our thermal imaging reportage, that’s why it’s one of the best in the industry, this is obviously a part of the service which is off-site and clients don’t see. Whilst we may draw initial conclusions on-site, which may need more investigation; usually, our final conclusions and report will only be finalised after all the data has been studied. It’s our ongoing aim to provide thermographic reports that are clear, concise, and easy to reference. Our aim is to take the guesswork out of the equation.

Please contact us for more information on Thermal Inspection Services

Our team of Level 2 & 3 certified professional Thermographers is highly experienced in carrying out thermal imaging surveys and have many years of experience in all aspects of engineering, construction, maintenance, management, and professional survey work.

Our thermal imaging equipment is the best and most accurate on the market, ensuring we pick up faults that other equipment may miss. Our reports are professionally presented and are clear, concise, and easy to follow. We endeavour to give our clients a first-class service every time.

If you would like to contact us for more information on our thermal imaging services, please contact us on 01525 303905 or email us at info@aptsoundtesting.co.uk. Alternatively, if you would like more information on how to prepare for your thermal imaging survey, please visit our website or download our thermal imaging checklist.