Sound Proofing Walls for Precompletion Sound Testing

Sound Proofing Walls for Precompletion Sound Testing

Many people who phone us with noise complaints, say they can hear the neighbours talking to each other across the and they are not even shouting! Excess noise can be debilitating, distressing, and upsetting which can lead to health problems if left unchecked.

Sound transfer between walls and floors in dwellings is a common problem of attention to detail in many cases has resulted in poor-quality construction – this is often down to the contractors installing party walls and floors being on price work resulting in poor workmanship.

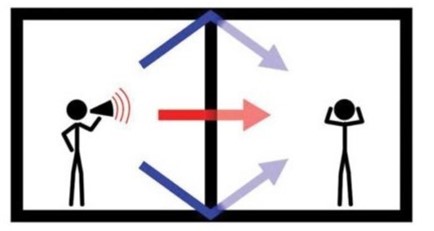

Excess sound transfer occurs as a result of airborne noise (tv, voices, music, etc). The airborne sound wave strikes the wall, and the pressure variations cause the wall to vibrate resulting in noise. This noise (vibrational energy) is transferred through the wall partition and radiated as airborne sound on the other side.

The main issue is often due to the lack of mass of the masonry wall construction. If lightweight (thermalite) blockwork has been used (or a single 70mm metal partition) there is a much higher chance that the wall will fail a sound insulation test due to its lightweight construction. Taking the above into account it’s critical that the acoustic design of the party wall is considered from the start of the project.

The 4 main elements of good soundproof design

There are 4 main elements of soundproofing that need consideration throughout the process, all of which have a direct relation to the conduction and transmission of sound vibrations.

- Adding Mass: if the wall construction has a higher mass, the soundwave will struggle to vibrate the wall itself in order to permeate through it as it will have less movability, making it less probable for sound vibrations to travel through.

- Adding Decoupling: with decoupling, you can introduce a cavity between two layers of drywall which separates the two wall constructions. By doing this, a layer of air is created in-between the walls which provides good sound insulation.

- Adding Absorption: acoustic Insulation material such as RW3 mineral wool (min mass 45kg/m3). The material is placed into the wall in order to absorb these soundwaves, but the insulation is not compressed.

- Adding Damping: such as acoustic underlay There are several products that are used for this, and Green Glue (check my review) is a popular option. Green glue helps in converting some of the sound energy to heat energy.

All elements of soundproofing are major influences for the way in which soundwaves and vibrations behave within the space. The best results come through the inclusion of all of these four elements in relation to the physical properties of the wall.

What can you do retrospectively of the wall fails the sound insulation test? It is difficult to soundproof an existing party wall particularly around adjoining partitions such as floors and ceilings.

Sound Proofing Masonry Walls

In all, there are three main ways to soundproof a masonry party wall:

- For High mass Masonry – apply a layer baton to the wall, then add resilient bars and a later of 15mm sound insulation board. This only needs to be done to one side of the wall, where high mass masonry has been used.

- For Low mass Masonry – apply a layer baton to the wall, then add resilient bars and a later of 15mm sound insulation board. This needs to be done to both sides of the wall, where low mass masonry has been used.

- Where high levels of sound insulation are required – Creating a new partition wall – using 70mm met-sec with a cavity void to the party wall, fill the metal frame with acoustic insulation (min mass 60kg/m3) and finish with 2 layers of Acoustic Plasterboard. Unfortanly, this reduces the width of the room by up to 125mm.

Sound Proofing Metal Walls

In all, there are three main ways to soundproof metal party wall:

- For internal metal walls –fill the metal frame (min width 70-100mm) with acoustic insulation (min mass 45kg/m3) and install 1 x 15mm layer of soundboard to either side of the metal frame.

- For dividing metal walls – fill the metal frame (min with 100mm) with acoustic insulation (min mass 60kg/m3) and attach “resilient channel” to the studs and install 2 x 15mm sound board to either side of the wall.

- For high spec dividing metal walls – use 2 x 70mm met-sec wall, with a 50mm cavity. Fill both metal frames with acoustic insulation (min mass 45kg/m3) and finish with a single layer of 15mm Acoustic Plasterboard.

If the walls are existing i.e., it is a conversion project, you may need to gain access to the base and head of the party wall, to undertake the acoustic upgrades within floor and ceiling voids, this is also required to reduce the chance of flanking noise.

Unfortunately, retrofitting to improve sound insulation performance is difficult to achieve and not always 100 per cent successful. We always recommend you have sample sound testing undertaken between dwellings before embarking on expensive insulation works and on conversion projects. For block of flats, it’s worth remembering that you will need to consider require both airborne and impact sound tests to ensure compliance with the 2014 Building Regulations Technical Guidance Document E (Sound). For houses you just need to consider walls.

For more information on our UKAS accredited sound testing or acoustic design services, please contact us at info@aptsoundtesting.co.uk or call us on 01525 303905. Alternately for more information on how to prepare for your precompletion sound testing please download our sound testing checklist, or visit our website at www.aptsoundtesting.co.uk