Sound Testing Walls

APT provides acoustic design and sound insulation testing and consultancy to help architects, developers and homeowners achieve the minimum requirements of Part E of the Building Regulations for new build and/or conversion projects. Sound transfer between walls in dwellings is a common problem and its often down to poor-quality construction – this is often down to the contractors installing party walls and floors being on price work and not taking time and care during the construction process resulting in poor workmanship.

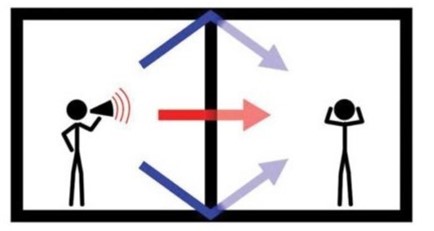

Sound Testing Walls & Sound Transfer

Excess sound transfer occurs as a result of airborne noise such as tv, music, voices. The airborne sound wave strikes the wall, and the pressure variations cause the wall to vibrate resulting in noise. This noise (vibrational energy) is transferred through the wall partition and radiated as airborne sound.

The 4 elements of robust soundproof design to pass party wall sound testing

There are 4 main elements of soundproofing that need to be considered to pass sound testing through walls. It’s worth noting that all 4 elements throughout the process, all of which have a direct relation to the conduction and transmission of sound vibrations, they are: Mass, Decoupling, Absorption and Damping. If you incorporate all the four elements into your party wall design, then airborne sound transference should be kept to a minimum and you will pass your precomplation sound testing.

If all four elements are undertaken to your project, then there is a higher chance you will pass your party wall sound insulation testing at the first attempt.

Adding mass to pass party wall sound testing

The first element of a robust soundproofing design is the adding of mass. if the wall construction has a higher mass, the soundwave will struggle to vibrate the wall itself in order to permeate through it as it will have less movability, making it less probable for sound vibrations to travel through. One the most common ways to add mass by the inclusion of cement board or soundboard. This adds mass and makes the walls as heavy and thick as possible. Adding mass to walls is one of the easiest ways to decrease sound vibration, although will not reduce deep bass sounds from being heard.

Working out required mass required for wall to pass the sound insulation test can be quite difficult. For instance, the acoustic rating of a typical masonry wall increases from 45 dB to 50 dB when the thickness is increased from 100 mm (block laid on edge) to 215 mm (block laid flat). This doubling of mass does not need to be achieved by a doubling of thickness of a wall, as you can greatly increase the mass by opting for a masonry that has a minimum mass of 1900kg/m3 or (190/m2) whereas many lightweight blocks such as thermalite are only 500kg/m3 (50kg/m2), which can easily lead to sound test failure if used in the wrong situation such as the inner envelope construction and or a single skin construction for party walls.

It’s worth remembering for sound to conduct through a wall, it has to actually move or vibrate the party wall ever so slightly. A heavy mass wall is always much harder to move than a lighter wall. It is very important to note that a heavy wall will still vibrate, just not as easily as the lighter one, with this in mind we then need to use the 2nd element of soundproofing design which is the Decoupling of materials.

If all the above updates relating to adding mass are undertaken to your project, then there is a higher chance you will pass your party wall sound insulation testing at the first attempt.

Adding Decoupling to Pass Party Wall Sound Testing

The second element of a robust soundproofing design is decoupling. Basically, the term definition of decoupling is to separate objects or construction. With decoupling, you can introduce a cavity between two layers of drywall and/or masonry which separates the two wall constructions. By doing this, a layer of air is created in-between the walls which provides good sound insulation. Decoupling materials within party wall construction is mostly done with resilient sound clips, resilient acoustic channel, or extra framing i.e., double stud or staggered stud walls. In most instances, sound vibrations will transfer easiest from material to material with solid connections, rather than through open space such as cavities.

In our experience coupled wall constructions usually have the worst sound insulation performance, this is because the sound has a solid sound transfer path via the direct fixed plasterboard to the framing and then through the direct fixed plasterboard on the other side. To improve the sound insulation performance of the party wall you need to introduce acoustic decoupling by reducing the number of connections by installing resilient sound clips, or by breaking the path entirely via the introduction of a 2nd wall leaf and cavity.

Resilient sound clips are small metal and rubber connections that attach to the timber of blockwork with screws. Resilient bars are then installed to the clips and plasterboard is then fastened to the channel. Sound clips provide acoustic decoupling by suspending the plasterboard on the resilient bars approx. 25-40mm from the timber or blockwork wall. This type of system is often favoured by developers as it has a minimal build up in comparison to constructing a double leaf wall with cavity and is much quicker to install.

If all the above decoupling updates are undertaken to your project, then there is a high change you will pass your party wall sound insulation testing at the first attempt.

Adding absorption to pass party wall sound testing

The third element of a robust design is the introduction of noise absorption materials within the party wall construction. In all cases, careful selection of good quality soundproofing insulation materials will contribute towards a successful sound test in compliance with Approved Document E. Absorption materials can be acoustic slabs and acoustic rolls.

The introduction of acoustic insulation materials such as Gyproc RW3 mineral wool (min mass 45kg/m3) can be a good place to start. The material is placed into the wall in order to absorb these soundwaves, but the insulation is not compressed. Acoustic insulation is good at removing low-level noise issues and can be quite easy to handle and install. The acoustic slabs are dense and effectively block out noise frequencies across party walls and floors in blocks of flats etc.

When you’re working on metal of timber stud walls, you can simply insert the acoustic slab straight onto the wall, making sure it’s fitted neatly between the metal /timber studs with no sagging or holes in the material. You can then install the rest of your acoustic solution such as resilient bars and acoustic plasterboard and apply an acoustic sealant around all gaps and holes.

If all the above absorption updates are undertaken to your project, then there is a higher chance you will pass your party wall sound insulation testing at the first attempt.

Adding damping to pass party wall sound testing

The 4th element of a robust soundproofing design (or acoustic design) is the introduction of noise damping within the party wall construction. Noise damping materials can be acoustic resilient layers and rubber panels which help to reduce vibration within the party wall construction. Dense recycled rubber panel systems are high performance wall soundproofing solution aimed at providing good noise damping performance. Unlike other acoustic solutions, this dense recycled rubber is fairly easy to install and will provide a reliable soundproofing-barrier.

Noise damping materials are usually quite easy to fit, as the acoustic rubber panels just need to be cut to size and stuck to the party wall covering the entire party walls surface. Proprietary adhesives are usually supplied with the rubber panels. The wall can then be finished off by adding two layers of acoustic plasterboard. When used correctly, this simple upgrade system, can improve the performance of a single skin brick wall by 7-10dB or achieve 46dB to 48dB Dnt, W +CTr which exceeds the requirements of Approved Document E for party walls 43dB Dnt, W +CTr in conversion projects.

If all the above damping upgrades are undertaken to your project, there is a higher chance of passing your party wall sound insulation testing at the first attempt.

Watch out for noise flanking transmission through party walls.

Flanking sound transmission occurs when sound is transmitted from one space to another indirectly, through adjoining parts of the structure. For example, impact sound may be transmitted from one room to another via a continuous timber floor, but also through the supporting wall. This can be as simple as the party wall been built straight off the top of the timber floor finish, so the noise travels under the party wall via the continuous timber floor.

Another common noise flanking issue encountered on many office conversions, is the inclusion of lightweight (thermalite) blockwork in the original inner envelope and party wall construction. The mass of a blockwork wall should be approx. 1850kg/m2; however, a standard thermalite block may be as low as 450kg/m2, approx. one quarter of the recommend mass. This means the noise can pass to neighbouring flats via the lightweight walls, even when the party wall has been designed and built to pass Part E by a large margin.

Flanking noise transmission is always a potential problem within any structure buildings being converted and depending on the intensity of the acoustic energy received via flanking transmission paths, the effectiveness of sound insulation of separating partitions can be much lower than expected from their construction. We often carried out precompletion sound testing to wall partitions that should have achieved around 50dB, but only achieved 40dB, due to onsite noise flanking resulting in sound test failure.

Careful consideration must be given to the effect of flanking noise transmission within all party walls within new and conversion projects, and all potential flanking paths must be identified and eliminated prior to the installation of any sound insulation system.

If all the above noise flanking considerations are employed on your contract, then there will be a much higher chance you will pass your party wall sound insulation testing at the first attempt.

Sound proofing masonry party walls to pass precompletion sound testing

There are many soundproofing solutions for masonry walls; however, it depends on what types of masonry have been used for the existing/new wall construction. To try and help you on your soundproofing journey, I have listed four acoustic solutions for masonry walls; however, each solution should be carefully checked with the material manufactures prior to onsite installation.

Here are three ways to soundproof a masonry party wall:

- For High mass Masonry – Check that all masonry and mortar pointing is complete, then apply a timber baton to the wall, then add resilient bars and a layer of 15mm sound insulation board. This only needs to be done to one side of the wall, where high mass masonry has been used.

- For Low mass Masonry – Check that all masonry and mortar pointing is complete, then apply a layer baton to the wall, then add resilient bars and RW45 acoustic insulation. finish with 15mm Sound Board. This needs to be done to both sides of the wall, where low mass masonry has been used.

- For Low mass Masonry (higher spec) – Check that all masonry and mortar pointing is complete, then apply a Gyproc G.L 1 wall lining solution to the wall, then add RW45 acoustic insulation to the inside of the metal frame. Then finish with two layers of Sound Board.

Where high levels of sound insulation are required – Check that all masonry and mortar pointing is complete, then creating a new partition wall using 70mm met-sec with a cavity void to the party wall, fill the metal frame with acoustic insulation (min mass 60kg/m3) and finish with 2 layers of Acoustic Plasterboard. Unfortunately, this reduces the width of the room by up to 125mm.We can help with the party wall sound proofing design

Sound Proofing Metal Party Walls to Pass Precompletion Sound Testing

Metal stud walls are the most common type of interior wall; however, they are also extremely popular when it comes to party walls between dwellings. While metal walls are quick and easy to install, they’re really not very soundproof. Luckily, it’s possible to soundproof a stud wall, although it will take some acoustic design knowledge.

One of the simplest ways of soundproofing a metal stud wall is to isolate each side of the wall and add mass. To soundproof a stud wall effectively, you can either add a completely independent wall in from of the existing wall, although you can also attain the required soundproofing levels by upgrading the existing wall.

Here are three common ways to soundproof your metal party wall:

- For internal metal walls –fill the metal frame (min width 70-100mm) with acoustic insulation (min mass 45kg/m3) and install 1 x 15mm layer of soundboard to either side of the metal frame – please note this will not comply with the levels required for Approved Document E.

- For dividing metal party walls – fill the 100mm metal frame (with Rw45 acoustic insulation (min mass 45kg/m3) and attach “resilient channel” to each side of the studs and install 2 x 15mm sound board to either side of the wall.

- For high spec dividing metal party walls – use 2 x 70mm met-sec wall, with a 50mm cavity. Fill both metal frames with acoustic insulation (min mass 45kg/m3) and finish with a single layer of 15mm Acoustic Plasterboard.

If the walls are existing i.e., it is a conversion project, you may need to gain access to the base and head of the party wall, to undertake the acoustic upgrades within floor and ceiling voids, this is also required to reduce the chance of flanking noise.

The importance of sample sound testing for Part E compliance

Unfortunately, retrofitting to improve sound insulation performance is difficult to achieve and not always 100 per cent successful. We always recommend you have sample sound testing undertaken between dwellings before embarking on expensive insulation works and on conversion projects as this provides an accurate overview of the sound insulation performance of existing walls and floors, as well as highlighting noise flanking issues. For block of flats, it’s worth remembering that you will need to consider require both airborne and impact sound tests to ensure compliance with the 2014 Building Regulations Technical Guidance Document E (Sound). For houses you just need to consider walls.

Our roadmap to sound testing success

APT Sound Testing works with hundreds of builders, architects and property developers helping them with the acoustic design of their developments. Consequently, we are well placed to understand the challenges that adequately sound proofing party-walls poses to new build and/or conversion projects. Our roadmap to soundproofing success includes:

- Sample Sound Insulation Testing – We undertake sample sound testing to identify the sound levels for the existing party walls and floors. Thereafter a more targeted acoustic design can be undertaken to the partitions saving time and money through the construction process.

- Acoustic Consultancy – We have considerable experience in all matters related to architectural acoustic design and detailing. We can help develop the initial acoustic design of the project from the initial design scheme stage, in particular acoustic isolation, and interior acoustics. We also use the latest Norsonic equipment analysers and sound sources for conventional and binaural acoustic measurements.

- Site Visits – we undertake site visits which allow you (the client) and your contractor to feel confident about the outcome of testing at the end of the build. The site visits let us check that the installation teams are installing the acoustic materials as per manufacturers avoiding crucial onsite mistakes. You can often have a compliant design which still fails due to poor workmanship; the site survey visits negate the risk of sound test failure.

- Precompletion Sound Insulation Testing – We visit site and undertake the final pre-completion testing to ensure compliance with Building Regulations Part E and achieve building control sign off for the acoustic elements of the project.

Using our friendly and proactive approach our acoustic engineers will work with you to achieve the required level of performance, however complex the project. Using the APT Sound Testing team, you will benefit from:

- all in one acoustic solution, that considers sample sound testing, acoustic design, and final pre-completion sound testing.

- vast amount of technical knowledge gained from providing consultancy on a wide range of projects for over 25 years (from small housing developments to multi-residential, mixed-use, or commercial sites) as well as experience from carrying out over 10,000 sound insulation tests.

- ongoing impartial independent advice – we are not affiliated with any acoustic manufacturers so the advice you receive is completely impartial. All correspondence with you remains strictly private and confidential.

- we endeavour to provide the cheapest acoustic solution to try and reduce costs and buildability issues. This will an off the shelf solution wherever possible.

Getting the soundproofing design right from the word go, is key, and APT Sound Testing can help in all areas of acoustic design and sound insulation testing. For more information on our UKAS accredited sound testing or acoustic design services, please contact us at info@aptsoundtesting.co.uk or call us on 01525 303905.

Alternately for more information on how to prepare for your precompletion sound testing please download our sound testing checklist, or visit our website at www.aptsoundtesting.co.uk

Please Note: although we take every care to ensure the information was correct at the time of publication. Any written guidance provided does not replace the user’s professional judgement. It is the responsibility of the duty-holder or person carrying out the work to ensure compliance with relevant building regulations or applicable technical standards.