Thermal Imaging Survey & Electrical Systems

10 reasons for undertaking a thermal imaging survey on electrical systems.

The are hundreds of reasons why you should undertake thermal imaging to electrical systems within your building; however, here is the top 10 reasons:

- Safety of electrical systems: Thermal imaging can identify overheating components, loose connections, and other issues that may lead to equipment failure or fire hazards resulting in injury or even loss of life!

- Preventive Maintenance: It helps avoid reactive repair and replacement costs. By being proactive, you can help reduce operating costs.

- Energy Efficiency: A single critical fault can mean additional energy costs. Thermal imaging can help identify such electrical faults, so repairs can be made to reduce running costs.

- Cost Savings: On average, each infrared electrical inspection reveals five to eight faults, highlighting the relative affordability of this predictive service. Its also one of the quickest inspections so defects can be quickly identified.

- Fire Safety Compliance: NFPA 70B prescribes annual infrared inspections for electrical systems. A comprehensive infrared inspection can discover hidden defects, prevent unplanned failures, business interruption, equipment damage, and insurance losses.

- Insurance Premium Reductions: In some cases, your business might qualify for a reduction in insurance premiums by conducting annual predictive/preventive maintenance thermographic surveys.

- Non-Intrusive: Electrical thermal imaging surveys are non-intrusive, enabling inspections to be completed safely and efficiently, without interruption to your business operations and/or critical assets.

- Planning Maintenance: Electrical thermography inspections enable the identification of only those items of equipment that require remedial works together with the severity of the defect. This enables maintenance to be suitably planned around operational commitments.

- Extend Equipment Lifecycle: An electrical thermographic survey can give an excellent insight into the operational effectiveness of equipment, enabling the identification of opportunities to make energy savings together with increasing the operational lifecycle of equipment.

- Reduction in Breakdown Costs: Depending on the type of equipment and its location, the cost of electrical failure can run into many thousands of pounds in repairs, lost production, injury claims, etc. As defects are found before they cause equipment to fail, the associated cost of repairs is minimal compared to the cost of equipment failure and/or accidents in the workplace.

How often should an Infrared Electrical Inspection be undertaken?

Ideally an electrical thermal imaging inspection should ideally be conducted every 6 to 12 months as part of the electrical preventive maintenance program. However, the frequency can vary depending on the equipment history, problems associated with its location, or adverse environmental concerns. For businesses with heavy usage equipment, such as busy manufacturing plants, it’s recommended to carry out a thermal imaging survey every 12 months. Regular inspections can help ensure safety, energy efficiency, and cost savings on critical assets.

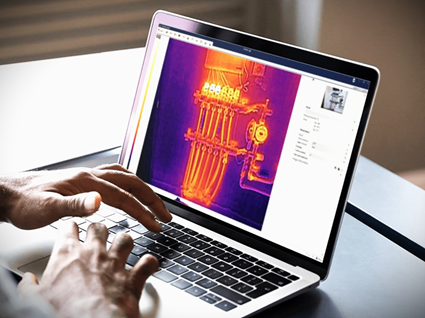

Our thermal imaging inspection service for electrical systems

Our team of Level 3 certified professional Thermographers are highly experienced in carrying out thermal imaging surveys and have many years’ experience in all aspects of engineering, construction, maintenance, management, and professional survey work. Our thermal imaging equipment is some of the most accurate on the market, ensuring we pick up faults that other equipment may miss.

Our thermal imaging service includes:

- Supply of an ITC trained thermographer and level 3 reporting assessment using a large format FLIR P6n-Series (640×480 resolution) thermal imaging camera.

- To supply an external thermographic inspection of the electrical systems, taking into account, distribution boards, fuse boards, Switchgears, switchboards, Control panels, Busbar systems and Transformers.

- Looking for loose connections, overloaded and/or fatigued components, uneven voltage distribution and blockages in cooling tubes of transformers

- A detailed report clearly showing any areas of concern

For more information on our thermal imaging service for electrical systems in London, please contact us at: info@aptsoundtesting.co.uk or call APT Sound Testing on 07775 623464.