What is an Air Tightness Test?

What is an Air Tightness Test?

Air leakage (also known as air permeability or air infiltration) is the air tightness of a dwelling through uncontrolled means such as cracks and gaps in the building envelope – walls, floors and ceilings.

Any ventilation system installed within a building is classified as a source of controlled air flow and is therefore not considered as air leakage and so these areas can be temporarily sealed during the air tightness test.

Air leakage is often felt as unwanted draughts, which will lower internal temperatures and may cause discomfort to building occupants especially in cold and windy weather.

Air tightness testing is a method of measuring and quantifying the air leakage of a building. Building Regulations Part L1A relates to dwellings and Building Regulations Part L2 refers to commercial buildings.

Within the documents Air Tightness Testing is referred to as Pressure Testing and is the method by which developers measure the air tightness of their residential and commercial developments. Air testing shows how well properties will retain heat and in turn reduce carbon emissions, making them more efficient and cheaper to maintain.

An Energy Performance Certificate (EPC) is another compulsory requirement under Part L1A of the Building Regulations for all newly built residential and commercial units and these can only be issued when the air pressure testing results are available, to include within the SAP Assessment and thereafter the EPC.

How does Air Tightness Testing work?

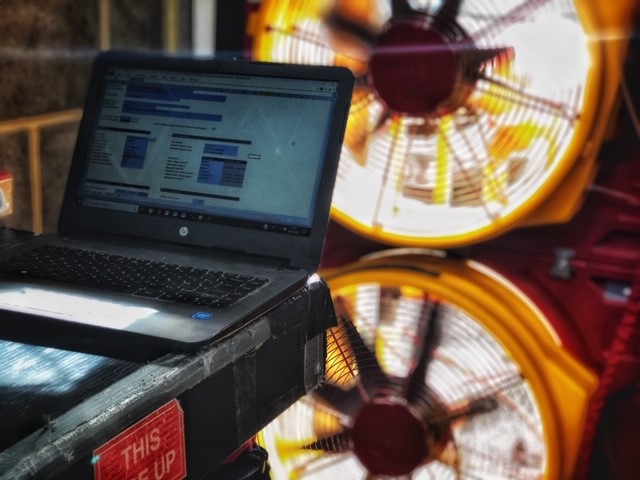

Air Tightness tests are carried out by increasing the air pressure within the dwelling/building and then measuring the rate by which the pressure returns to normal. This is carried out using large fan/s inserted in the entrance doorway. The number of units you will have to test will depend on the number of unit types on your development. For most dwellings a single fan will be sufficient to pressurise the building; however, for larger commercial units a multi fan system will be required which is usually set up in blocks of 3 fans to each doorway.

What Air Permeability Figure do I need to achieve?

The Design Air Permeability for the dwelling/building will be determined initially by the lead consultant or SAP/SBEM assessor. The maximum design air permeability allowable is 10 m3/(m2.hr) @50Pa; however, this the more common figure of 5 m3/(m2.hr) @50Pa is often used. By aiming for a reduced Design Air Permeability and improving levels of air tightness it will serve to further reduce carbon emissions and make the Target Emission Rate (TER) easier to achieve. It may also mitigate the cost of more expensive carbon emission reduction strategies.

There are many common areas of air leakage; or air leakage paths within dwellings and commercial buildings, they are: Behind Bath Panels, Kitchen and Utility Units, Intermediate Floors, Behind Skirting Boards, Boxed in Pipes & Soil Stacks, Fireplaces, Poorly Installed Trickle Vents, Windows and Doors, Recess Lights & Loft Hatches.

Special attention should be shown to the above areas throughout the construction process.

Another interesting fact is that UK studies have demonstrated that a house/flat with robust air tightness credentials can often attain a higher sale price due to reduced energy costs over the lifetime of the building.

Building Regulations Part L and ATMMA TS1 both offer lots of useful information in regards to Air Tightness Testing, such as which plots should be selected and what parts of the building can be temporally sealed etc. If you would like more information on how to prepare your building to pass an air tightness test then please download our air tightness checklist.

Please Contact us now

If you would like more information on our air tightness testing service, then please visit our website at www.aptsoundtesting.co.uk or contact us at: info@aptsoundtesting.co.uk. To have a chat about your project please call: 01525 303905