Airborne & Impact Sound Testing in London

Sound Testing usually needs to be carried out between pairs of rooms separated by party walls and/or floors. Most sound tests are carried out between living rooms and bedrooms as these are classed as the two main habitable rooms; however, other rooms can be used if this is not possible such as studies, kitchens, and dining rooms.

Our Sound insulation testing procedure is fairly simple and straightforward. Essentially, for party walls there is only one type of sound insulation test which is the airborne sound test; however, for party floors, there is a requirement for two types of sound insulation testing – airborne & impact sound testing. Here is a brief description of each type:

Airborne Sound Testing in London

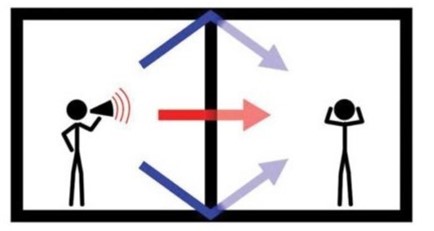

Airborne Sound Testing is carried out by means of a loudspeaker emitting a steady source of noise on one side of the partition (wall or floor) to be measured. The corresponding sound level is measured on the other side of the partition. Impact sound insulation tests are carried out by means of a tapping machine placed on the floor sample to be measured and the noise measured in the room or space below. Calculations are done based on these measurements and the above-mentioned parameters are calculated and compared to the Building Regulations Part E sound insulation requirements for the given type of building. It is important that the building to be sound tested is completely finished and sealed with no sound leakage through doors and windows. Please see our checklist for sound testing for more information.

Sound Testing in London

Airborne sound insulation testing is undertaken on walls & floors. Firstly a controlled noise is generated by an amplifier and loudspeaker across a broad range of frequencies. The generated noise is very loud and is often in excess of 100dB. Initial measurements are taken using a class 1 sound level meter within the ‘source room’ followed by further measurements in the ‘receiver room’ on the other side of the wall or floor under investigation. The source room speaker position is then changed and the measurements are repeated on either side of the partition under test. Thereafter background noise measurements are made using a class 1 sound level meter in the receiving room and are used to apply appropriate corrections for external sounds such as traffic noise. Similarly, the reverberation time (the time taken for sound to decay by 60dB) is measured within the receiving room using the sound source and a sound level meter to determine the corrections that must be applied to account for the characteristics and absorptiveness of the room. The difference in the two airborne noise levels (for walls and floors), corrected for background and reverberation characteristics determines the airborne sound insulation performance of the wall or floor. A greater airborne noise difference between the source room and the receiver room determines a higher airborne sound insulation performance.

The time taken to undertake sound testing varies from project to project as no site is exactly the same. Taking into account standard site conditions a set of tests on houses -two airborne walls will take one to two hours. A six-pack of tests on flats – 2 airborne wall tests will usually take between one and two hours, although this is dependent on our engineers having full free uninterrupted access between all the units/rooms under investigation.

Impact Sound Testing in London

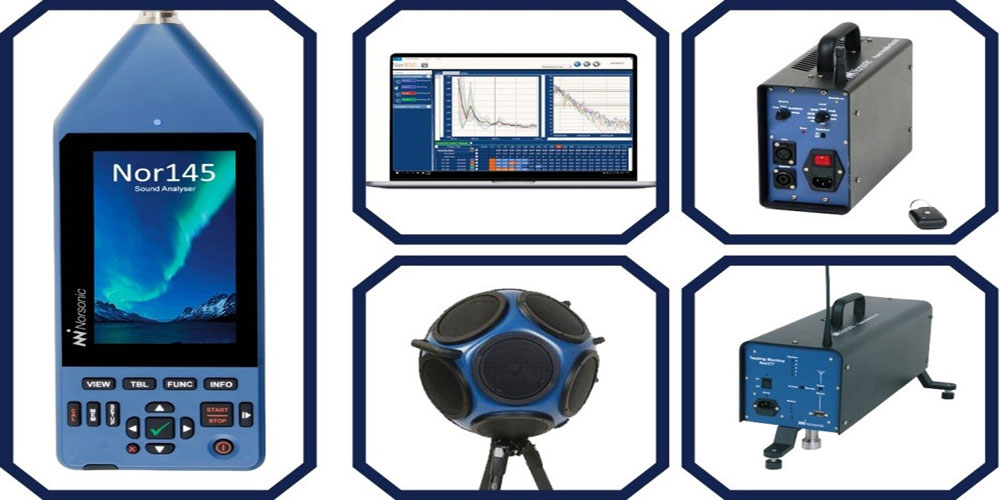

Impact sound testing is undertaken on floors only. This test is different; a calibrated Norsonic ‘tapping machine’ which comprises five ‘hammers’ driven up and down by a cam and electric motor is used to “tap” the floor surface by applying a known force on the floor structure. The machine is placed in several pre-determined positions. The resulting noise is measured in the dwelling below, using a sound level meter. Thereafter, background noise measurements are made using a class 1 sound level meter in the receiving room and are used to apply appropriate corrections for external sounds such as traffic noise. Similarly, the reverberation time (the time taken for sound to decay by 60dB) is measured within the receiving room using the sound source and a sound level meter to determine the corrections that must be applied to allow for the characteristics and absorptiveness of the room.

The time undertaken to test each project varies from project to project as no building/development is exactly the same. Taking into account standard site conditions a set of tests on houses that consist of two airborne walls will take approx. 1-2 hours. A six-pack of tests on flats consisting of 2 airborne walls, 2 airborne floors, and 2 impact floor tests will usually take approx. 2-3 hours, although this is dependent on our engineers having full free uninterrupted access between all the units/rooms under investigation.

If you require sound testing, and/or acoustic design advice then please contact us now at info@aptsoundtesting.co.uk or direct on 01525 303 905 or visit our website at www.aptsoundtesting.co.uk