UKAS Accredited Sound Testing Services

At APT Sound Testing, we offer comprehensive UKAS-accredited sound testing services across London and throughout the UK, fully compliant with the stringent standards outlined in Approved Document E of the Building Regulations. Our sound testing solutions cater to a variety of building types, including residential properties, commercial structures, educational institutions, healthcare facilities, and mixed-use buildings designed for both residential and commercial purposes.

Our expert team of sound testing engineers is highly experienced in managing all aspects of acoustic compliance. We understand the critical importance of meeting the required acoustic standards to ensure successful building completion. As part of our services, we offer bespoke acoustic design advice to help clients address noise-related challenges proactively. Our goal is to ensure that all our clients meet the necessary standards for sound insulation and noise reduction, making the testing process smooth and efficient.

Expertise in Sound Testing

At APT Sound Testing, our team brings extensive knowledge and experience to every sound testing project we undertake. We specialize in testing for compliance with the Building Regulations Part E, and our engineers are experts at identifying and addressing potential acoustic issues early in the process. Our services are applicable across a wide range of projects, from new residential developments to complex commercial and mixed-use spaces, educational buildings, and healthcare facilities. We are committed to providing the highest standards of service to all our clients, regardless of project size or complexity.

Sound Testing for Residential Buildings

For residential projects, whether it is a new-build house, apartment complex, or housing development, our sound testing services are crucial in ensuring that the building meets the necessary acoustic performance criteria. We carry out a range of tests, including airborne sound insulation (measuring sound transfer between rooms) and impact sound insulation (measuring sound transfer between floors). Our expert team helps self-builders, developers, and contractors ensure their projects comply with acoustic standards outlined in Approved Document E.

Sound Testing for Commercial Buildings

In commercial spaces, noise control is equally important to ensure a comfortable and productive environment for employees, customers, or tenants. APT Sound Testing is equipped to perform comprehensive sound testing for office buildings, retail spaces, and other commercial environments, ensuring that these spaces meet required acoustic regulations. Whether you are constructing a multi-storey office block or a retail development, our team will work with you to ensure compliance with the relevant regulations.

Acoustic Testing for Educational Facilities

Schools and universities must maintain quiet, controlled environments to support effective learning. Our acoustic testing services help ensure that classrooms, lecture halls, libraries, and study areas provide the necessary acoustics for education. We assess the noise transfer between rooms, particularly in areas where speech intelligibility and concentration are critical.

Healthcare Facilities

For healthcare buildings, including hospitals, clinics, and other medical facilities, our sound testing services are tailored to meet the needs of a sensitive environment. Quiet spaces, free from disruptive noise, are vital to patient care and well-being. Our testing ensures that all rooms, including patient wards, treatment areas, and waiting rooms, meet the required acoustic performance standards.

Mixed-Use Developments

Many urban developments now combine both residential and commercial spaces. For mixed-use developments, acoustic performance becomes a particularly important consideration to ensure that residential areas are not disturbed by the noise from commercial spaces. APT Sound Testing works closely with developers to ensure that these types of spaces meet both residential and commercial sound insulation standards.

Acoustic Consultancy and Design Advice

At APT Sound Testing, we don’t just perform testing, we offer comprehensive acoustic consultancy services designed to help clients navigate the challenges of noise control from the very start of the project. Our team works closely with architects, developers, and contractors during the planning and design stages to assess potential noise-related issues, offering tailored recommendations to ensure successful compliance.

Tailored Acoustic Solutions

Our approach to acoustic consultancy is highly personalized. Every project presents its own unique set of challenges, and our team works to create customized solutions for each client. Whether it’s advice on soundproofing, designing noise barriers, or assessing building materials for their acoustic performance, we provide expert recommendations that help prevent problems before they arise.

Early-stage Collaboration

We work with clients from the outset of a project, providing insights during the initial design phase. By identifying potential acoustic challenges early, we help clients incorporate noise mitigation measures into their designs, making it easier to meet the necessary standards later. This proactive approach ensures that clients avoid costly design changes and delays in the later stages of construction.

UKAS Accreditation

One of the most significant benefits of working with APT Sound Testing is our UKAS (United Kingdom Accreditation Service) accreditation. This accreditation guarantees that our sound testing services meet the highest standards of quality, precision, and reliability. UKAS accreditation means that our testing processes and equipment undergo regular, rigorous checks, ensuring that we provide accurate, trustworthy results every time.

We adhere to the ISO/IEC 17025 standard, which governs the competence of testing and calibration laboratories. This ensures that all our sound testing services are carried out with the utmost professionalism and that our results are recognized by all relevant authorities. As part of our commitment to quality, we use the latest testing equipment, all of which is UKAS calibrated, ensuring the highest level of accuracy in every test.

Integrated Testing Solutions

In addition to our sound testing services, we offer air tightness testing as part of our comprehensive service package. For many clients, combining both sound and air tightness testing helps streamline the process and reduce overall project costs. By offering both services as part of an integrated package, we simplify the testing process and help clients avoid complications that can arise from coordinating multiple testing providers.

Air Tightness Testing

Air tightness testing is an essential part of ensuring that buildings are energy-efficient and comply with Part L of the Building Regulations. The combination of sound and air tightness testing makes it easier for clients to achieve compliance with multiple regulations at once, saving time and money.

Why Choose APT Sound Testing?

Commitment to Quality and Excellence

We are dedicated to providing the highest quality service to our clients. Our team is made up of highly trained professionals who are not only technically skilled but also committed to delivering outstanding customer service. From the moment you contact us, you’ll experience a seamless, professional service designed to meet the specific needs of your project. Our in-house team ensures that every part of the testing process is handled with care and precision.

Client-Centric Approach

At APT Sound Testing, we understand that every project is unique. That’s why we offer a personalized service tailored to your needs. Our team is responsive, reliable, and always available to provide guidance, answer questions, and ensure that you receive the best possible service. Clear communication is at the heart of our client-focused approach, ensuring that you are always informed and confident throughout the testing process.

Proven Track Record

With years of experience in the industry, APT Sound Testing has built a solid reputation for delivering accurate, reliable testing services. Our client base includes a diverse range of sectors, from residential developers and commercial contractors to public sector organizations, including healthcare providers and educational institutions. Our reputation for quality service is reflected in the high rate of return clients we have, many of whom continue to trust us with their projects due to the excellent service we provide.

Our Service Areas

Based in central London, APT Sound Testing offers nationwide coverage, serving clients throughout the UK. Whether you are located in London, the South East, the Midlands, or beyond, we are ready to assist with your sound testing needs. Our flexible service ensures that we can accommodate last-minute requests and weekend work, particularly for high-priority sectors like banking and finance.

Contact APT Sound Testing

APT Sound Testing is your trusted partner for UKAS-accredited sound testing and acoustic consultancy services across London and the UK. Our expertise, commitment to quality, and comprehensive approach to sound and air tightness testing make us the ideal choice for anyone seeking reliable and precise acoustic testing solutions. Whether you are working on a residential development, a commercial project, or a specialized healthcare facility, we have the knowledge and experience to help you meet your acoustic requirements.

For more information or to schedule a consultation, please call us at 01525 303 905 or contact us through our website. We look forward to working with you on your next project and helping you achieve the acoustic performance you need for successful building completion.

# About the Author

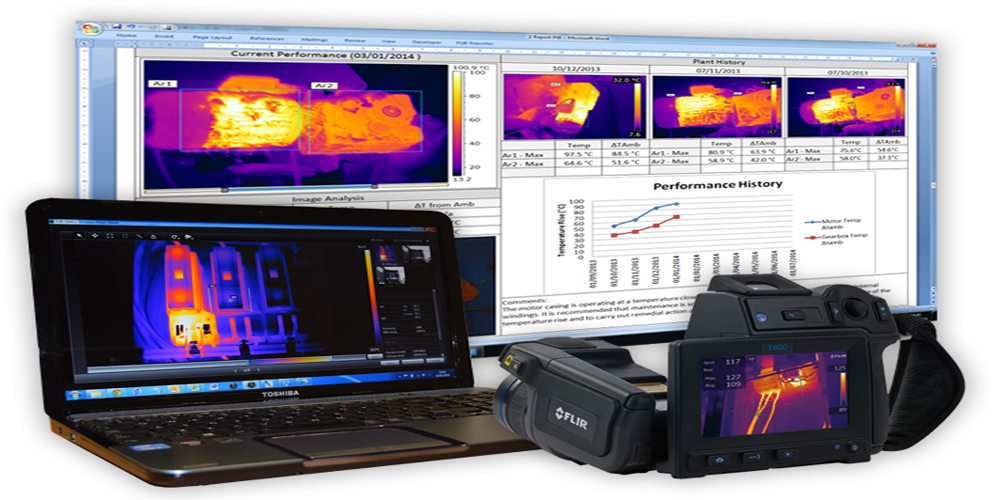

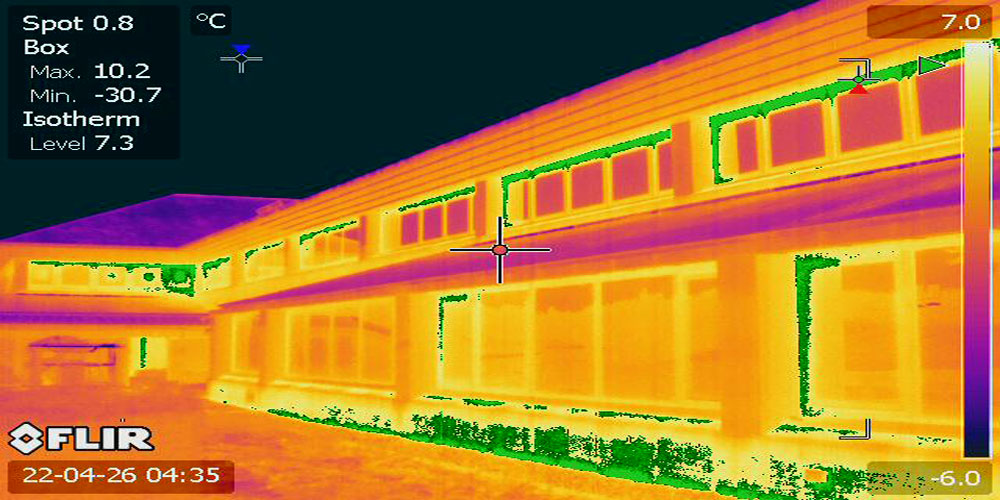

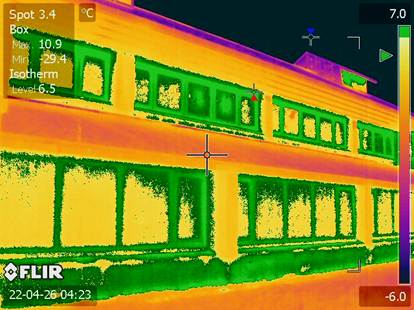

Darren Helliwell is a building performance specialist with over 25 years of hands-on experience leveraging thermal imaging, blower door testing, and smoke analysis to optimise air tightness in both new-build and refurbishment projects such as Battersea Power Station, Imperial War Museum and Harrods.

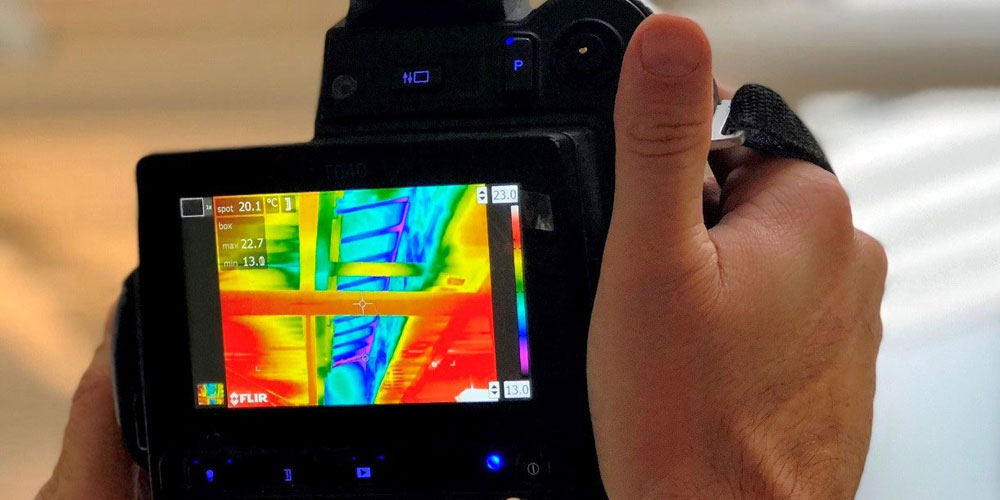

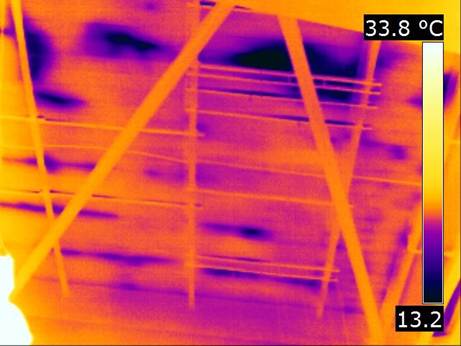

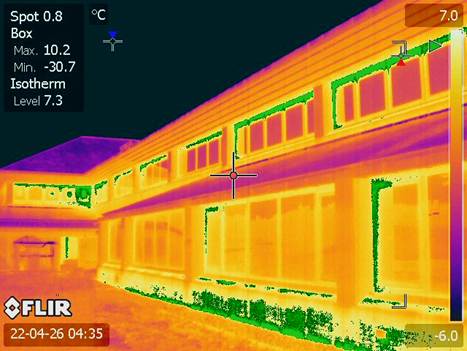

Using advanced infrared thermal imaging cameras alongside state-of-the-art blower door and smoke-testing equipment, Darren’s team delivers detailed thermographic surveys across residential and commercial buildings. These thermal imaging surveys pinpoint invisible air leaks, identify insulation defects, and reveal thermal bridging—empowering architects, contractors, and property owners to make targeted, energy-saving improvements.

Darren’s ongoing mission is to help design teams and contractors harness the power of thermal imaging to achieve truly airtight, energy-efficient building envelopes. By reducing heat loss and driving down energy bills, his thermography expertise supports sustainable, cost-effective construction and refurbishment outcomes.

Connect with Darren Helliwell:

[Thermal Imaging Surveys] Thermal Imaging Surveys | APT Building Thermography Reports

[APT Email] info@aptsoundtesting.co.uk

[LinkedIn] https://www.linkedin.com/in/darren-helliwell-78789b26