Extractor Fan Testing Overview

Extractor Fan Testing Overview with APT Sound Testing

In adherence to the new regulations outlined in Part F of Building Regulations, it is now mandatory for standard intermittent extractor fans, commonly found in bathrooms and kitchens of new buildings, to undergo air flow rate measurement on-site. These results must be submitted to the building control body before completion and handover.

Our service facilitates extractor fan testing concurrently with air and sound testing, streamlining coordination efforts and offering significant cost efficiencies. Rest assured, our operations are conducted by a UKAS accredited company, ensuring quality and compliance.

Importance of Extractor Fan Testing

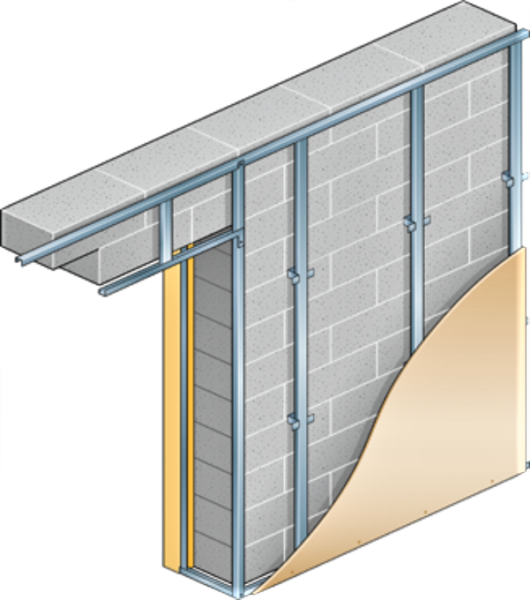

As modern buildings prioritize insulation and air tightness, it’s imperative that ventilation systems are appropriately installed, balanced, and commissioned to ensure optimal operation for occupants’ well-being. Approved Document F mandates that Mechanical Ventilation and Heat Recovery (MHVR) systems, along with intermittent extractor fans, have their flow rates verified, ensuring efficient operation. These test results are integral to building compliance and sign-off procedures.

In typical circumstances, we conduct Ventilation Flow Rate testing concurrently with on-site Air Pressure Testing, enabling streamlined compliance with both Part L and Part F regulations.

Best Practices Guide

a. Confirm ductwork complies with manufacturer specifications. b. Minimize duct bends to optimize airflow and minimize resistance. c. Use flexible ducts solely for connecting units to central diffusers to maintain acoustic performance. d. Employ recommended duct jointing collars and components for optimal duct performance. e. Seal all grilles and ductwork penetrating the building’s air barrier to ensure continuity. f. Ensure correct placement, securing, and adjustment of fans. g. Verify internal doors have 10mm undercuts as per regulations. h. Electrician should set fan speed according to manufacturer data. i. Secure air handling units to stable building elements using recommended fixing brackets. j. Install units in accessible positions for maintenance.

Expert Consultation

For guidance on achieving compliance with approved Document F and domestic extract fan testing, contact our knowledgeable consultants via the provided contact form or phone our offices. For assistance in preparing your building’s ventilation system for compliance, reach out to our team for tailored vent testing solutions. Use our contact forms or call our offices to discuss your specific requirements with our experts.

Sound Testing and Acoustic Design Services

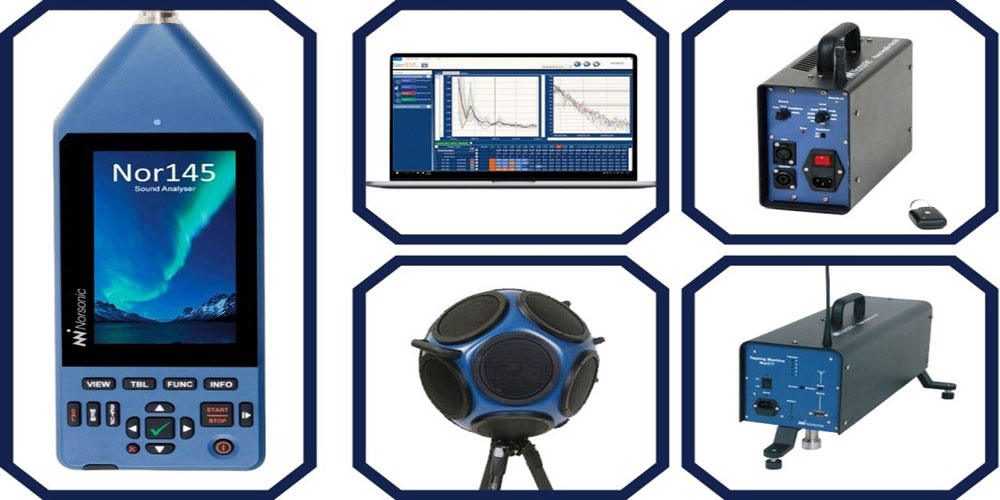

Here at APT Sound Testing we offer a friendly and proactive design, consulting, and precompletion testing service for all your compliance and certification requirements.

We undertake sound testing on all types of residential buildings and commercial buildings. We also undertake sound testing on schools and buildings containing rooms for residential purposes.

Our team of experienced sound test engineers are dedicated to giving our customers the best quality of service and offer acoustic design advice where possible, to help our clients achieve the required acoustic results to pass the sound testing and attain building completion. We can also undertake ‘in house’ UKAS accredited air tightness testing in one seamless package, lowering costs and negating coordination issues.