Clean Room Testing

APT Cleanroom Services can undertake all your cleanroom testing requirements including the organisation of maintenance programmes to ensure your cleanroom is in compliance with the corresponding ISO standards. If you would like more information on our cleanroom services please contact us at: info@aptcleanroomtesting.co.uk or phone Darren directly on: 07775623464. We offer an immediate proactive service to minimise downtime to your critical asset/s.

PROVIDING CLEANROOM TESTING FOR DIFFERENT FOR INDUSTRIES

We undertake cleanroom testing too many industries from Biotechnology through to the automotive industry all with different ISO requirements.

Here is a list few of the main industries:

Biotechnology and Pharmaceutical Cleanroom Testing

Many biotechnology and pharmaceutical cleanrooms are specified at ISO Class 5 to ISO Class 8 and apply to a large portion of the cleanroom standards. If you're not familiar, ISO classes and standards are set by the International Organisation for Standardisation.

The many ISO standards provide various requirements, specifications, guidelines and characteristics that can be used consistently to ensure that materials, products, processes and services are fit for their intended purpose.

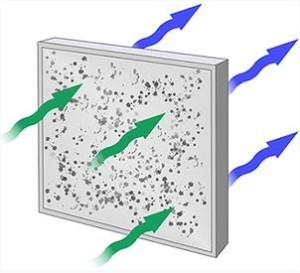

In all cleanrooms, particulate matter is a great concern. Specifically, viable particulate contamination should receive careful consideration and attention. Viable particulate contamination refers to the ability to keep the room clean by typically using modular or stick-built components with integral cove bases and corners, as well as coved ceilings in order to maintain a cleanable surface condition. This high grade finish is crucial for biotechnology and pharmaceutical cleanroom standards.

In all instances concealed areas may allow for bacterial growth which is unacceptable. These clean rooms typically use cleanroom technology that keeps the seal unbroken during sanitation and filter changes. Biotechnology and pharmaceutical cleanrooms typically have a heavy focus on pressurisation control, the elimination of cross contamination and the ongoing filtration of outdoor air and indoor air.

Defence Industry Cleanroom Testing

The defence and optic industries use cleanrooms for many of their applications, including biotech, pharmaceutical, and medical device. These applications may also include items such as like chip making for controlling missiles and electronic and radar components, laser technology for guidance systems and even biological components for vaccines etc.

Defence Industry Cleanrooms usually require the highest levels of security and clearance. Due to the sensitive/high security nature of various defence industry operations, this typically leads to the stick-built type of construction to allow for the perimeter to meet government security requirements.

Medical Device Cleanroom Testing

Cleanrooms for medical device technology typically fall under ISO Class 7 and ISO Class 8 range. As you can imagine the manufacturing process for these products ensures that the surface of the product does not have particulate contamination when it is completed. So, it is imperative that the cleanliness level inside the room is maintained both from a cleanroom standpoint.

In many cases people/personal is the major contaminator in most processes. This is why personnel are required to wear full gowns, booties, gloves, and hairnets in medical device manufacturing, as well as the biotech, pharmaceutical and semiconductor industries. While some medical device cleanrooms may not always adhere to the same stringent gowning practices as pharmaceutical cleanrooms, the protocol and cleaning process is just as important. The cleanroom environment for medical devices usually aims to eliminate surface contamination, or viable particulate, on their products.

Microelectronic and Nanotech Cleanroom Testing

Microelectronic and Nanotech Cleanrooms are designed to maintain temperature, humidity, particulate, static and pressure levels. This is due to the fact that these factors, as well as static forces, can easily affect or compromise the final product, taking into account the huge costs associated with these types of works there's simply no room for error.

A high level of cleanliness must be maintained at all times within nanotech and microelectronic cleanroom environments since defects can occur at any stage in this process. Many steps are involved in order to come to a final product, and a defect along the way might not be discovered until the very end. Most of these cleanrooms typically operate in a cleanroom classification range from ISO Class 1 to ISO Class 6 with various processes occurring at different levels of cleanliness.

Automotive Cleanroom Testing

Since the early invention of the assembly line, the automotive industry has made incredible strides in their manufacturing processes. Indeed, a wide range of attention is given to mass defects, or preventing them. Like other industries the need for manufacturing auto components inside cleanrooms has become a key factor in the automotive industry.

In Automotive Cleanrooms factors like pressure, temperature and humidity are just as important to other rooms designed in the cleanroom classification range of ISO 7 and ISO 8. The defects that can (and do) occur in the automotive manufacturing industry are vast, including costly errors like glass coatings, electrical components, and painting to the bodywork.

THE CRITICAL ROLE OF CLEANROOMS

On a day to days basis cleanrooms play a critical role in maintaining contamination free production environments for critical processes. To ensure all cleanrooms are working as designed it is essential that a well-planned cleanroom testing and maintenance program is undertaken for operation and regulatory compliance. APT cleanroom testing offers a comprehensive clean room testing service and clean room certification for the clean room industry.

Using our technical knowledge and experience in cleanroom testing coupled with our steadfast commitment to quality and the highest standards of customer service we provide customers with reliable, accurate and thoroughly documented clean room testing programme. It is our ongoing aim to minimise facility down time as we are acutely aware that clean rooms the main critical asset to most companies.

In Pharmaceutical, Biotech, and Medical Device cleanrooms, it is imperative that companies know if any airborne contaminants put products at risk. It is also very important to understand what the contaminants are, and their origin. Important environmental measurements, like airborne viable particle measurements, assist with keeping processes in control and with helping to find the root cause of unwanted events to monitor cleanrooms for viable particles and other potential contaminants to ensure a clean environment is maintained at all times.

We undertake a cleanroom testing service in accordance with international standards and customer quality specifications. Cleanroom test protocols and report documentation can be customised to customer specifications.

Our primary cleanroom tests include:

" Non-viable particulate monitoring

" HEPA filter integrity testing

" Airflow volume/velocity profiling

" Room air exchange rates

" Room pressurisation monitoring

" Temperature and humidity monitoring

OUR MOST COMMON CLEAN ROOM TESTING SERVICES

In order to ensure that your clean room environment is working effectively a number of factors relating to the air supply coming from your ventilation need to be tested. These tests apply to every type of clean room, whether used for the manufacture of pharmaceutical products, sterile and aseptic production or Microelectronic production.

We usually need to test the quantity of air to ensure that there is enough to dilute or remove any contamination generated within your clean room, and we will need to test the quality of the air to ensure that it is not adding to any contamination, rather than removing it.

We also need to test the flow of the air to ensure that it is moving from clean to less clean areas, minimising the movement of any contaminated air into your clean area, and also to ensure there are no areas of the room with high concentrations of pollutants.

In order to carry out these tests, for every clean room we are working in, we will measure and check:

1. Airborne particulate testing - We will carry out measurements to ensure that the concentration of particles and micro-organisms is compliant with the specification set out for your clean room.

2. Filter installation leak testing - Your ventilation system's high efficiency particulate air (HEPA) filter, and its housing will be tested with DOP (Dispersed Oil Particulate) to ensure their integrity.

3. Air supply and extract quantities - If your air supply is unidirectional we will measure and record the air velocity, while for non-unidirectional systems we will measure air supply.

4. Differential pressure - Here we will be testing to ensure that the air in your clean room always moves from clean to less clean areas, with your clean room having a higher pressure than adjacent less clean areas.

5. Containment leak testing - We will check the construction of your clean room to ensure that no airborne contamination can occur via leaks from higher pressure work areas adjacent to it.

6. Air movement control - Studying the movement of the air within your clean room we will check that there is sufficient air movement to dilute or remove pollutants, preventing any contamination build-up.

7. Room recovery - Reviewing the effectiveness of airflow we will measure how quickly a clean room recovers to its normal operating cleanliness following a release of particulate contaminant.

8. Temperature, Relative Humidity - We may also need to carry out tests on temperature, relative humidity, and the heating and cooling capabilities of the room, as well as noise, lighting and vibration levels.

APT Clean Room Testing will always try to ensure that you fully understand our process and your results, following any clean room testing or validation service, we will present you with clear, easy to follow cleanroom test reports that can be compiled, quality checked and issued to you while still on site, minimising the down time of your operations.

We are customer driven and continually try to exceed our customers' expectations, both in terms of price and service. Our careful attention to detail ensures that our reports and certificates are of the highest quality and customers can be confident that their external calibration and validation requirements have been met. Our commitment to quality is backed up by our UKAS accreditation. Our test engineers are well trained, highly motivated and flexible individuals who ensure constant and consistent delivery of our high standards.

If you have a clean room that requires particulate monitoring or any of the above testing then please get in touch with us as soon as possible as we should be able to offer you an expedient solution for all your cleanroom testing and certification. We can also offer maintenance programmes to ensure your cleanroom is in compliance with the corresponding ISO standards- it's why we place such emphasis on the process of 'expert intervention'.

THE MOST COMMON TYPES OF CLEANROOM TESTING

In our experience the most common types of cleanroom testing are:

" Non-viable particulate monitoring

" HEPA filter integrity testing

" Room air exchange rates

" Airflow volume/velocity profiling

" Temperature and humidity monitoring

" Room pressurisation monitoring

Here is some more information for each the most common types of testing.

PARTICULATE TESTING TO CLEANROOMS

Clean room facilities such as pharmaceutical and Semiconductor and manufacturers are examples of environments that require demanding ongoing air monitoring and periodic certification. An accurate air monitoring and testing system is the only method for these clean room facilities to maintain that level of cleanliness needed during environmentally sensitive production. Particle counters can activate alarms when contamination poses immediate threats to manufacturing processes thus warning the end user of potential risk from contamination. Also, these cleanroom particle counters can document emerging contamination trends and weak spots within the process to guide cleaning personnel in maintaining air quality in their critical environments.

As the manufacturing process becomes more efficient and refined, along with the onset of Nano technology with more products produced in the same space during the same amount of time, the greater potential monetary loss in the event of contamination in a clean-room environment. The greatest threat used to be the human component of the process. In a minienvironment, numerous sources of contamination can exist including fan filter failure, excess contamination build up or mini-environment integrity failure.

In all these instances the only way to prevent losses is to catch a contamination event as it happens via particulate testing. As production evolves, so must we monitor and evolve with it. To keep up with manufacturing efficiencies, we can check the particulate counts using the latest equipment to accurately and continuously monitor several locations within each minienvironment. To remedy clean room contamination, a highly sensitive handheld particle counter can be used to locate the source of particle emissions. We can also carry out the periodic particulate testing and forward the necessary certification.

How Often Should I Undertake Particle Testing

In January 2016, ISO introduced an update to standards ISO 14644-1:2015 - Classification of air cleanliness by particle concentration and ISO 14644-2:2015 and monitoring to provide evidence of cleanroom performance related to air cleanliness by particle concentration.

APT Cleanroom Testing have received many questions in regards to what impact the updated standard has on validation and testing frequency. It is essential that your undertake clean room particle testing to prove it complies with ISO 14644-1:2015 - Classification of air cleanliness by particle concentration. This ensures that your cleanroom continues to perform efficiently and enhance your ongoing business process,

Within ISO 14644-2:2015 - Monitoring to provide evidence of cleanroom performance related to air cleanliness by particle concentration; recommends customers to complete risk assessments and monitoring plans to determine the frequency of testing and validation to their individual cleanroom processes.

It states the maximum time interval between airborne particle concentration testing for cleanrooms of ISO class 5 and below at six months and ISO class 6 and above at 12 months.

Here is a quick table showing this in more details.

| Test Parameter |

Class |

Max Time Interval |

| Airborne particle concentrations |

ISO Class 5 |

|

| Schedule of additional tests |

ISO Class 5 |

|

| Airflow velocities in unidirectional airflow |

All classes |

|

| Airflow volume supply in non-unidirectional airflow |

All classes |

|

| Pressure differentials |

All classes |

Schedule of additional tests

Airflow velocities in unidirectional airflow All classes> 6 months

Airflow volume supply in non-unidirectional airflow All classes 12 months

Pressure differentials All classes Continuously monitored

Using our technical knowledge we are able to provide our clients with a reliable clean room particle testing service to comply with ISO 14644-1:2015, ensuring optimal cleanroom performance and minimised facility down time.

HEPA FILTER TESTING TO CLEANROOMS

HEPA Filters - High Efficiency Particulate Air filters are devices which remove solid particles such as pollen, dust and bacteria from the air. HEPA Filters are used to remove ultrafine dust, aerosols and viable organisms. High Efficiency Particulate Air filters are most commonly found within operating theatres and patient isolation rooms within hospitals, cleanrooms and laboratories but also for micro-electronics, optical and pharmaceutical production.

Why HEPA Filters Are Used on Cleanrooms

Good quality Filters are necessary in a cleanroom to remove various different types of contaminant from the air and ensure the right level of air purity is maintained consistently. Filtration provides protection for people working in the confined space, as well as for production and the surrounding environment.

The choice of a ventilation system for a cleanroom is a major decision and must be carefully considered. In many instances design advice from experts will be required to highlight which equipment is most appropriate. As well as the design and layout of the area, other key points to bear in mind include the type of application and the direction of airflow which is needed.

A critical ventilation system must have the right filters installed within it. High efficiency particulate air (HEPA) filters have to meet official standards including the British and European standard BS EN 1822-1: 2009. This means that, in factory testing, these filters must have an efficiency level of more than 99.995%.

A high quality HEPA filter will remove particles of solid contaminants including dust, mould, and bacteria room the air. It can screen tiny particles above 0.3 micrometres in size. There are various different types of HEPA filter available and they are frequently used in cleanroom settings within pharmaceutical and electronics production, as well as in hospitals and healthcare facilities.

Once ventilation equipment has been installed, it is vital to ensure it is working properly at all times and this includes checking and maintaining all filters in good condition. This is essential for the proper operation of a cleanroom and for regulatory compliance. Filters are tested by the manufacturer before they are supplied, to ensure they meet set relevant standards. However, initial clean room testing also needs to be carried out on-site as soon as they have been installed; this is to check that damage has occurred since manufacture, such as during the installation and/or transportation. Regular HEPA filter testing is necessary to ensure the integrity of the filters. Normally filters are built to last between 1 and 4 years, but various faults can occur which mean they are no longer providing the intended protection.

We can advise you on how frequent testing needs to be for your specific cleanroom. Systems which come under the COSHH regulations, providing protection to people from hazardous airborne particles, will require testing at least once a year. Some Hepa systems need to be tested more frequently, in some cases every six months. The level of risk usually dictates the frequency of the required testing.

HEPA Filter Maintenance & Testing

As an integral part of your ventilation system, high efficiency particulate air (HEPA) filters require regular maintenance and validation, and DOP testing plays an essential role in this. HEPA filter testing forms a part of the regulatory requirements for operations relying on specialist ventilation, and needs to be carried out in a consistent way to ensure reliability. Dispersed oil particulate (DOP) testing needs to be carried out to check whether filters are working correctly. This test involves releasing DOP into a cleanroom's airstream and then carrying out measurements to check that the filter has dealt with it correctly. The integrity of every filter component is fully checked during the testing process.

APT Clean Room Testing carry out DOP (dispersed oil particulate) Hepa filter testing to industry standards to ensure clean rooms and other specialist or critical environments are operating to the highest standards and to identify any potential air leakage paths.

What is DOP (dispersed oil particulate) Filter Testing?

In most specialist ventilation systems, there will be a high efficiency particulate air (HEPA) filter. This works to remove fine powder and dust from the environment, providing particulate free, clean air in its place. A DOP HEPA test is used to determine whether these filters are performing to the standards deemed acceptable by your regulatory bodies, keeping your operations running cleanly and smoothly.

DOP testing involves releasing a cloud of dispersed oil particulate as an aerosol into the airstream, upstream of the filter. Measurements can then be taken to ensure that no seepage has occurred, either the filter casing/housing or through the filter itself.

Hepa Filter integrity testing provides assurances for all parts of the filter, including the seals, the housing of the filter, and the joints onto the duct work itself. During the Hepa Filter test, a check is also made to ensure that all of the air within the clean room is passing successfully through the filter, ensuring there is minimal contamination build up due to dead spots etc.

As well as being a part of your regulatory obligations, the HEPA filter testing for your specialist ventilation system should be carried out by qualified engineers to avoid costly mistakes. We are fully trained using the latest equipment to carry out your DOP filter test. Also, due to our air leakage experience and construction design experience we can quickly identify any potential air leakage paths.

How is a DOP HEPA Filter Test Carried Out?

HEPA Filter testing is carried out using the following procedure.

Firstly an inspection of the air supply system must be undertaken to identify a smoke injection point; and a safe means of injection ascertained. If it's found that pre and secondary filters need to be removed, power to the air handing unit must be isolated before the filter removal. If the DOP is to be injected downstream of the fan unit or in a positive pressure section of ductwork a blower pump will be set up adjacent to the injection point. Thereafter, an aerosol generator will be set up adjacent to the blower pump and power up the generator to warm up. If extension leads are required, we will ensure all cables are secured as not to present a tripping hazard.

Then an aerosol photometer will be set up in accordance with the filter manufacturer's instructions and attached to sample points; this will be fitted upstream of each HEPA filter under test. Whilst working in pairs our engineer operating the photometer will maintain regular communication with the support engineer controlling the smoke generator by means of site radio and/or mobile phones.

Using a photometer instrument, our engineer will measure upstream concentration of aerosol, calibrating as required. The DOP may need to be increased or decreased. The penetration of aerosol will then be measured using a photometer, scanning the filter face with measured overlapping strokes at a speed no greater than 5cm/s. The ISO 14644 Part 3 standard permits a maximum downstream limit of 0.01% penetration. Filter differential pressures and airflow volume will be measured using a micro manometer and an anemometer at suitable positions. All HEPA filters DOP tests are recorded on an easy to read test report for traceability.

FOUR REASONS FOR CLEANROOM CONTAMINATION

Throughout all cleanroom facilities, maintaining strict cleanliness and maintaining the highest standards is a monumental challenge. Everything, both inside and outside of the cleanroom, is a potential source of contamination. To reduce the chance of major contamination all operatives should be adequately trained and a cleanroom testing regime adhered to at all times.

Whether manufacturing pharmaceuticals or working with high tech semiconductors even the smallest stray particles in the air can cause disastrous results requiring expensive downtime and clean up procedures.

According to the NEBB (National Environmental Balancing Bureau), the number one cause of contamination within cleanrooms is due to its own staff. In some instances cleanroom operators and technicians are responsible for 70% to 80% of cleanroom contamination problems which is a massive cause for concern.

Reason 1 - Cleanroom Hygiene

It is essential that all cleanroom technicians maintain a high standard of personal hygiene. Poor personal hygiene can make a big difference when it comes to potential contamination within a highly controlled environment. If a person's hands and/or face are not completely clean, there is a much higher number of potentially damaging particles seeping out from under protective clothing, including dandruff, hair and loose skin. It is extremely important that operators are aware of the importance of good hygiene and are given clear instructions on this prior to working in the clean room environment.

All technicians should thoroughly wash their hands and face should be left without any excess lotions or makeup. Operators should also be fully dressed in appropriate cleanroom apparel at all times to prevent contamination from the natural shedding of skin and other particles from the body. Also, when considering cleanroom clothing, it is especially important to make sure the proprietary gloves and shoe coverings properly cover wrist cuff and ankle openings of the cleanroom garments when arms and legs are extended to prevent particles from escaping.

Reason 2 - The Correct Cleanroom Undergarments

While special cleanroom protective garments do a lot to reduce the possibility of contamination, they can be reduced even further if operators pay attention to the types of clothes they choose to wear to work. Fabric materials such as suede, velour and wool may shed fibres and form "fabric balls" that may introduce extra risks into the environment. If you wear good quality cotton etc. it should help to reduce excess fibres particles that may escape from cleanroom garments and lead to cleanroom contamination.

Reason 3 - Smoking

Residual smoke consists of particles that are left in the lungs and slowly emitted into the air after someone smokes a cigar or cigarette. If employees smoke during their break-time residual smoke can become a possible contaminant in even the most sterile of cleanrooms. If smokers rinse their mouths, it should assist in diminishing this potential risk. The best solution, however, is to use facemasks which will prevent residual smoke, as well as other particles in exhaled breath, from entering the controlled clean room environment.

Reason 4 - Adequate Operator Training

As the cleanroom operatives usually cause contamination at some point. Employees who don't understand why they need to follow certain procedures due to adequate training are more likely to overlook necessary protocols and eventually cause something to go wrong.

Everyone should be adequately trained and encouraged to follow all procedures, as well as make suggestions to improve them where necessary. Everyone has to work together to keep standards high and it's always an ongoing process.

A Brief History of Cleanrooms

The first cleanroom identified by historian's dates back to the mid-19th century, where sterilised environments were being used in hospital operating rooms, although not clean by today's standards they were none-the less clean for their time. Modern cleanrooms were created during World War 2 where they were created to produce and manufacture state of the art weaponry in a clean and sterile environment.

During the war, US and UK industrial manufacturers designed a colossal amount of hardware such as tanks, airplanes, and guns, this contributed to the success of the war by providing the military with weaponry that was needed at each juncture of the war.

It is known that the HEPA filters were being used throughout cleanrooms by the early 1950s. Some believe that cleanrooms date back to World War I when there was a need to segregate the work area to reduce cross-contamination between manufacturing areas; however no exact date can be found for the introduction of the first cleanroom.

Regardless of when they were introduced into the manufacturing world, contamination was one of the main problems and cleanrooms were the solution. Continually growing and constantly changing for the betterment of projects, research, and manufacturing, cleanrooms as we know them today are recognised for their low levels of pollutants and contaminants allowing for incredible scientific breakthroughs such as Nano Technology etc.

Prior to the creation of modern cleanrooms, early cleanrooms had contamination due to particles and unpredictable airflow throughout the room. With this in mind cleanrooms were created allowing for a constant, high-filtration airflow, which is what is used throughout cleanroom design and construction today.

Cleanrooms come in all shapes and sizes from small laboratories through to large manufacturing buildings. Cleanrooms are used for a variety of industries such as pharmaceutical production, scientific research, software engineering and manufacturing and aerospace engineering.

Though the cleanliness standards may have changed throughout the years, their purpose has always remained the same. Cleanrooms will continue to evolve as more and more research is conducted and air filtration mechanics continue to improve.

Seven things you didn't know about cleanrooms:

1. More and more food industries are using cleanrooms to manufacture products that rely on high sanitation standards, thus improving the quality of their products.

2. Cleanrooms are rated by their class, which is dependent on the number of particles found in the room at any given time.

3. Did you know that a motionless person standing in a cleanroom still emits more than 100,000 particles per minute? That's why it essential that the correct clothing is worn at all times.

4. The top four things that you need to wear in a cleanroom should be a cap, cover/apron, mask, and gloves.

5. NASA relies on cleanrooms to continue growth for the space program as well.

6. There are many different types of contamination that can contribute to product failure and inaccurate testing and results, such as micro-organisms, inorganic materials, and air particles.

We hope this article has been helpful and informative. If you have a clean room that requires a cleanroom testing service then please get in touch with us as soon as possible. We should be able to offer you an expedient solution for all your cleanroom testing and certification. We can also offer maintenance programmes to ensure your cleanroom is in compliance with the corresponding ISO standards - it's why we place such emphasis on the process of 'expert intervention'.

Please contact us at: info@aptcleanroomtesting.co.uk or phone Darren directly on: 07775623464.

APT Sound Testing Services

Head Office: Sayells Farm, 7 Harlington Road, Upper Sundon, Bedfordshire, LU3 3PE

Part E Sound Tests

Part E Sound Tests