Infrared Inspections to Electrical Installations

Infrared Inspections to Electrical Installations

Electrical Thermal imaging surveys detect abnormally high temperatures and are a non-disruptive way of inspecting electrical and mechanical installations.

It provides an extremely low impact fault diagnosis tool for electrical fault finding. It requires no contact being made with the components which means that the components can be checked in a live state with little danger to the user, there is no effect on the components or interruption in any processes the electrical system may be controlling, thus no downtime for server rooms and/or manufacturing plant etc.

Electrical faults can lead to breakdowns and the potential for fire hazards. In both cases the losses due to downtime and repair costs can become hugely costly.

What can cause failure in electrical equipment?

- The age of the equipment – gradual breakdown/wear and tear.

- Loose connections

- Overloading sockets in your workplace

- Loose or corroded contacts

- Load imbalances

- Poor cable joints

- Overloaded transformers

The most common electrical equipment that requires surveys are:

- Switchgears and switchboards

- Distribution boards and fuse boards

- Transformers

- Control panels

- Busbar systems

- High voltage systems

- Batteries

- UPS systems

- Heating and ventilation panels

- Motor and pumps

- Generators

Why should you undertake a thermographic survey?

Electrical thermal imaging surveys help to identify hot spots in electrical systems that you might not be able to see with the naked eye and makes sure that they are running safely. Thermographic surveys are low impact to the work environment so there is no down time for you to be affected by.

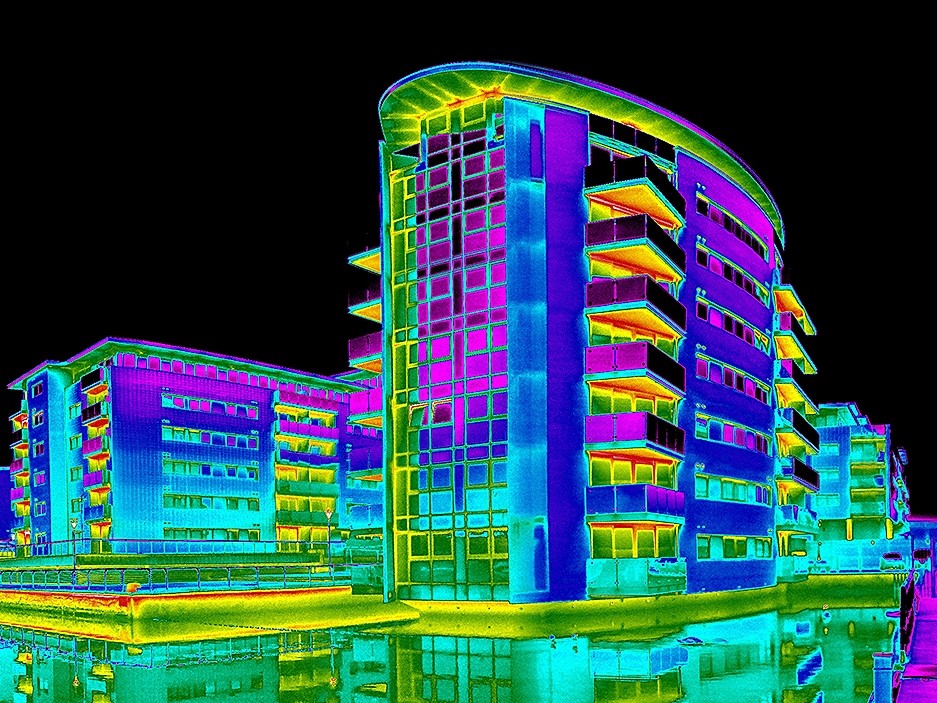

What type of Buildings need a thermal imaging survey?

- Commercial Buildings

- Office Blocks

- Schools and Colleges

- Warehouses & Storage

- Data Centres

- Military Infrastructure

- Flats, Houses & Residential Tower Blocks

- Housing Stock (Councils & Property Managers)

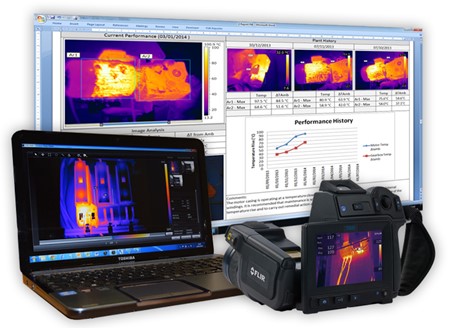

What does a Thermal image look like?

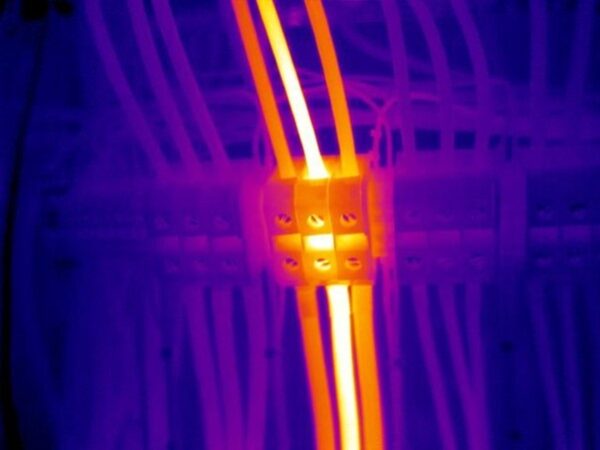

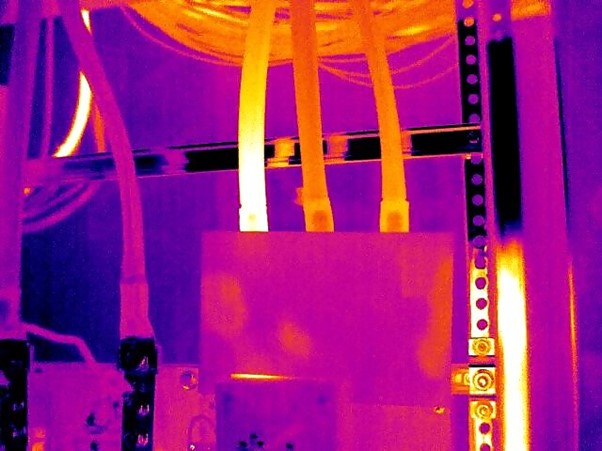

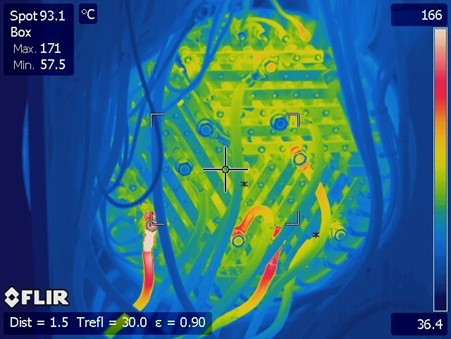

Based on infrared radiation, thermal images will have wide colour palate. The hottest areas of the thermal image from the thermographic survey will be yellow in colour, the coolest will appear in blue this provides a clearly defined imagine highlighting hot and cold spots.

Also, more expensive high resolution camera can be much more effective. The resolution of the camera is how many pixels the camera has on the scene. Higher resolution means that each image contains more information: more pixels, more detail, and a greater likelihood of getting an accurate measurement – that is why we always use cameras with a minimum of Resolution of 640×480 pixels along with Ultramax imaging for up to 1.2 MP thermal resolution. Here is some more information on why you should use high quality thermal imagining cameras.

How often should Thermographic inspections be carried out?

It is recommended that thermographic inspections to the electrical installations are carried out during the formal periodic inspections, which are usually carried out annually. Thermographic surveys of critical parts for an installation could mean they have to be isolated in order for them to be inspected. This would obviously cause disruption; however, a routine thermographic inspection of these parts will help your business to run and could identify underlying defects which in turn could lead to a failure of the electrical supply. This shows how important it is to have thermographic inspections routinely incorporated into the annual maintenance schedules, to stay safe.

How many issues can I expect to find within my building?

Historically, we usually find defects during each visit. This can be loose or corroded contacts, load imbalances, poor cable joints or an overloaded transformer – all of which will generate excess heat and previous data from thermal imaging of electrical installations shows a significant rate of potential fault detection for an initial survey, typically in the region of one to two faults for every 10 panels inspected – if you have 50 panels that may result in 10 faults!

A thermal camera can often show the problem before an electrical test or visual inspection would uncover it. The severity of the problem can be determined by comparing the temperature rise of the fault with the properly operating component under the same loading conditions.

Past data from thermal imaging of electrical installations shows a significant rate of potential fault detection for an initial survey, typically in the region of one to two faults for every 10 panels inspected.

How Much Does a Thermal Imaging Inspection Cost?

This one of the most common questions we get asked, and its has a simple answer: it depends on numerous factors. When we sit down to work out our fee proposal for a Thermal imaging inspection, we ask the client a number of questions:

- The type and size of building.

- The amount of preparation required.

- The amount of time required to safely undertake the survey.

- The type of equipment required to undertake the inspection.

- The project location and subsequent travel costs/time.

- The required deliverables – what needs to be included within the thermal survey report.

- The amount of health and safety requirements i.e., some sites ask for 4-hour safety inductions.

We pride ourselves from being able to offer a basic electrical thermal survey from as little as £495 plus Vat, right up to the huge industrial areas that may need to be done in multiple visits that may be over £10,000 plus Vat and everything in between. It’s always best to call us to so we can get a more accurate overview of our project and quote; accordingly, so please contact us to discuss your project (along with any site-specific issues) and obtain a quote.

Are you engineers trained to carry out a thermographic inspection?

When you are employing a thermographer, you should check to see that they incorporate the high specifications possible for their inspections. Are they certified to Level 3 and do they use large format FLIR thermal imaging cameras?

Their specification should include:

- Level 3 thermographic certification

- Level 3 qualified thermographers

- Large format FLIR cameras with 45-degree lenses

The importance of clear and concise thermographic reports

We spend much a large amount of time on our thermography reportage, that’s why it’s one of the best in the industry, this is obviously a part of the service which is off site and clients don’t see. Whilst we may draw initial conclusions on site, which may need more investigation; usually, our final conclusions and report will only be finalised after all the data has been studied. It’s our ongoing aim to provide thermographic reports that are clear, concise, and easy to reference. Our aim is to take the guesswork out of the equation.

Please contact us now.

If you require a electrical thermal imaging inspection our professional and certified Level 3 Thermographer’s will carry out your thermographic Inspections for all necessary standards and current regulations.

All we need are a few details such as the building address and the number of electrical installations within the building. Floor plans and would also be helpful to allow us to orientate ourselves during the inspection. We will also send across our informative checklist to help you prepare for the thermal survey.

If you would like to contact us for more information on our thermal imaging services, please contact us on 01525 303905 or email us at info@aptsoundtesting.co.uk Please call 01543 225306 or fill out one of our contact forms to discuss our service levels and to run a thermographic inspection for your business. Talk to us today so we can keep you and your business safe.