Pass Sound Testing in Conversion Projects

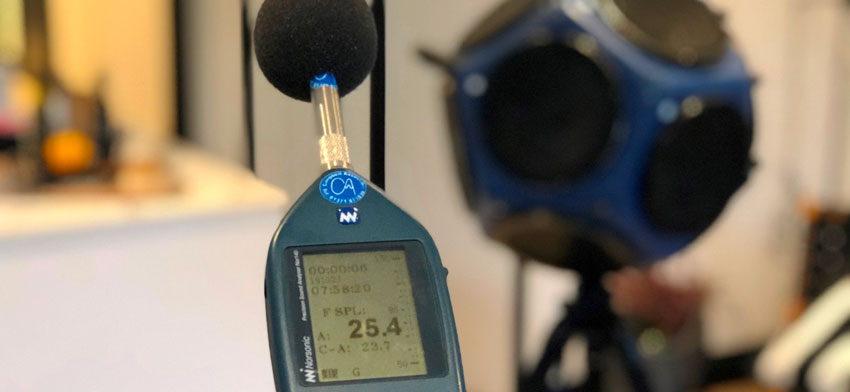

Robust Acoustic Design to Pass Sound Testing in Conversion Projects

It is essential that acoustic design is carefully thought out at the start of every conversion project to avoid sound test failures. Throughout the 1980s, most timber frame separating floors involved the following standard construction details:

- Floorboards (18–22mm thick)

- Gypsum-based board

- Mineral wool batt (80kg/m3)

- Sub decking

- 220mm joists

- 100mm quilt insulation between the joists

- One/Two layers of gypsum-based board for the ceiling

Using the combination of floorboard, gypsum board, and mineral wool batt is termed a “platform floor”. There is a wide range of batt densities. If the density is too low the floor surface is able to ‘bounce’ and deflect much more easily. If the density is too high then the floor may be too hard and impact sound is able to transmit more easily to the residential dwelling below.

Sound Testing in Conversion Projects

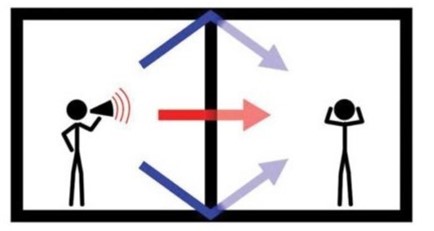

Even when resilient battens are used, continuous structural contact along the joist between the floor sub-deck and ceiling provides a strong path for sound transmission. If contact between the ceiling and the joists can be reduced, an increase in airborne and impact performance will be achieved.

One solution is to add another ceiling element to the overall construction. This can provide the extra isolation required to pass the sound testing in London. This can be achieved by incorporate resilient metal bars which are connected to the underside of the joists and mounted perpendicular (90˚) to the joist direction. If plasterboard has already been tacked to the underside of the joists you can firstly add timber batten and then add the resilient bars, also mounted perpendicular (90˚ to the batten.

Squeaking Floors

One common problem is that the Joists are often spaced too far apart can result in a reduction in floor stiffness and complaints about footstep noise at low frequencies. Over-notching of joists can also lead to a reduction in floor stiffness and also potential squeaking. This can result in successful airborne and impact sound tests, however, it won’t stop the squeaking of the floors under the extra load imposed by people walking above.

To help with impact sound testing, timber floors often pass as the separating floors normally have a resilient floor surface or “timber floating floor”. This not only assists impact sound insulation (against footstep noise transference) but also reduces airborne sound transference.

Timber floating floors must use a flanking strip to isolate the floorboards from the perimeter walls and skirtings. If flanking strips are not fitted then footstep noise can easily enter the structure via walls etc. and flank into the adjacent dwellings. In the 1980s, mineral wool was used as a flanking strip but it was difficult to turn round at the floorboard edge. It was also prone to deterioration due to compression and movement under dynamic load. As a direct result of this, 5–10mm polyethylene flanking strips were incorporated into the acoustic design and construction., They are also easier to install and do not degrade over time to the same extent.

There are many reasons why floors may fail the sound testing, such as the use of incorrect mechanical fixing can reduce the insulation performance provided by floating floor treatments and resilient ceiling bars. Using very long screws will lead to the bridging of the resilient layers and noise flanking. Inserting pipes or services within a platform floor can reduce the potential acoustic performance if they are not adequately boxed. Placing pipes or cables under resilient battens can also bridge the resilient layer.

Potential problems with timber frame separating floors

- Incorrect bridging of resilient layer by over-long screws/nails

- Fixings connecting ceiling boards to resilient bars should not bridge to joists

- Extra wide joist spacing that reduces floor stiffness

- Platform floor resilient layers damaged by inserting pipes and services within the layers

- Reduction in stiffness due to use of joist hangers

- Ceiling boards not staggered

- Over-notching of joists for services reduces floor stiffness

- Incorrect omission of flanking strips at floor edge perimeters.

Whilst it is normal practice to have a building surveyed for its structural integrity, however often the acoustic conditions of a building are not considered until the project is well advanced and the partitions are already built. In some cases, the acoustic performance of the building may not have been considered until the work is complete and the verifier requests a sound test to demonstrate compliance with the Building Standards. If it is found that the separating wall or floor does not comply you may need to action the following:

- Extensive remedial works may be required to the wall/floor partitions.

- The sound test completion certificate may not be accepted by the verifier

- There may be considerable delays to entry for occupants and subsequent accommodation costs.

- Pre-conversion sound tests can both avert the risk of non-compliance and avoid damage to the existing fabric.

Potential Problems with Services

It’s very common to run services such as electricity cables as well as water and gas pipes within the floor void. This is acceptable and should not require any additional acoustic attenuation measures. However, care should be taken to ensure that their installation does not damage the deafening material or resilient layers, which is a common cause of sound test failures.

It is strongly recommended not to run waste or rainwater pipes horizontally within a party floor. The pipes can then be boxed properly using insulation rapping and soundboard boxing.

Steel columns can be a source of flanking transmission, in particular hollow steel columns. They can also provide a strong path for structural impact transmission. Pre-conversion sound tests should be able to identify whether any columns act as a significant transmission path and whether any treatment is required. It may not be necessary to treat the column in all dwellings if flanking is limited, however, in many instances, the columns will need to be acoustically boxed to prevent sound test failure. One such treatment for columns would be to construct a free-standing metal stud partition around the column, incorporating 50mm insulation quilt and sheeted with two layers of gypsum-based board. Where columns pass through separating floors, as in old bonded warehouses, the junction between column and floor should be well sealed not only for sound insulation but also for fire. The column linings should be double lined with gypsum-based board (minimum mass per unit area 10kg/m2).

Timber beams do not significantly affect the sound insulation performance of a separating floor. However, if a beam has been installed for strengthening, the boxing around the beam may be a single sheet of lightweight board and may be fixed directly to the beam as this will result in a weak area for airborne sound insulation. This can be resolved by stripping off the boxing, packing any voids with dense mineral wool batt and re-sheeting with two layers of dense gypsum-based soundboard.

Contact APT Sound Testing

We hope the above information helps you to understand the potential problems with acoustic design and pre-completion sound testing on your development. If you have a project that needs acoustic design advice or sound testing in London, then please visit our Sound Testing website or phone us directly on 07775623464.