UKAS Accredited Sound Testing Services

At APT Sound Testing, we offer UKAS-accredited sound testing services across London and the entire UK, complying with the stringent requirements outlined in Approved Document E of the Building Regulations. Our expertise extends to a wide range of building types, encompassing both residential and commercial structures, as well as schools and buildings that house rooms for residential purposes.

Our dedicated team of sound testing engineers brings a wealth of experience to every project, ensuring that our clients receive the highest quality service. We understand the critical importance of meeting acoustic standards for building completion, and our engineers are committed to helping clients achieve the necessary acoustic performance to pass their sound tests. In addition to sound testing, we provide acoustic design advice to assist our clients in making informed decisions that will facilitate successful project outcomes.

Our goal is to support our clients throughout the process, from initial consultation to final testing, to ensure they meet all required regulations.

In addition to our sound testing services, we also offer UKAS-accredited air tightness testing, which can be integrated into our service package. By providing both sound and air tightness testing as part of a single, seamless process, we help our clients reduce costs and avoid the complications that can arise from coordinating multiple service providers. This integrated approach streamlines the testing process and ensures that all necessary compliance checks are completed efficiently and effectively.

Expertise in Sound Testing

At APT Sound Testing, our team of engineers is highly experienced in conducting sound tests across a diverse range of building types. Whether working on new residential developments, commercial buildings, educational facilities, or healthcare environments, our engineers apply their extensive knowledge to deliver precise and reliable testing results. Our commitment to quality service is reflected in the satisfaction of our clients, who benefit from our proactive approach and deep understanding of acoustic design principles.

We are proud to offer not only sound testing services but also comprehensive acoustic consultancy. This allows us to assist clients with the design and implementation of effective noise control measures, which can significantly enhance the likelihood of passing sound tests. Our engineers work closely with clients to identify potential acoustic challenges early in the project, providing actionable advice that can be incorporated into the design and construction phases. This collaborative approach helps to ensure that the final building meets all acoustic requirements, facilitating a smoother path to building completion.

Who We Serve

Our client base is diverse, ranging from individual self-builders to some of the largest housing developers in the UK. We also work with various public sector organizations, including the health authority and financial institutions, providing specialized services such as cleanroom testing. Over the years, we have built a reputation for delivering high-quality, reliable service that meets the unique needs of each client. Our commitment to client satisfaction is evident in our high rate of return clients, which is among the highest in the industry for pre-completion testing and consultancy services.

What sets us apart is our ability to provide a truly in-house service. Unlike many other providers, we do not subcontract our work. This means that every aspect of the testing process, from initial consultation to final reporting, is managed by our own team of experts. This approach allows us to maintain the highest standards of quality and consistency across all of our projects. Additionally, our central London office enables us to respond quickly and efficiently to client requests, offering the flexibility to accommodate last-minute testing needs and weekend work, particularly for clients in the banking sector.

Commitment to Quality and Innovation

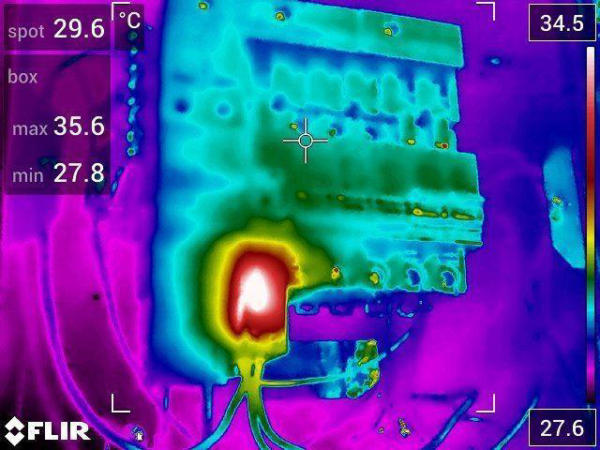

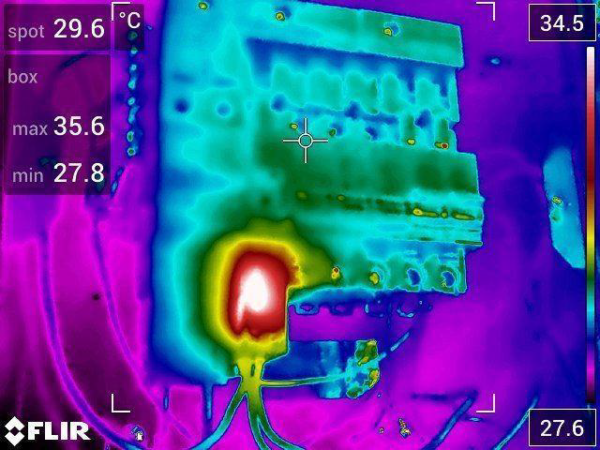

At APT Sound Testing, we place a strong emphasis on innovation and continuous improvement. We invest heavily in both our personnel and our equipment to ensure that we can provide the most accurate and reliable testing services available. Our engineers are trained to the highest standards, and we use the latest acoustic testing and survey equipment, all of which is UKAS calibrated to ensure accuracy. By keeping our team and tools at the cutting edge of the industry, we are able to offer our clients a service that is both efficient and of the highest quality.

We are also committed to listening to our clients’ needs and providing practical, cost-effective solutions that take into account the specific challenges of their projects. We understand that each project is unique, with its own set of requirements and constraints, and we tailor our services accordingly. Whether it’s providing acoustic design consultancy, conducting pre-completion testing, or offering advice on how to achieve compliance with Building Regulations, our team is dedicated to helping our clients succeed.

A Client-Focused Approach

Our approach to client service is built on the principles of responsiveness, reliability, and professionalism. We recognize that our clients rely on us to deliver critical services that are essential for the successful completion of their projects, and we take this responsibility seriously. From the initial inquiry to the final report, we strive to make the process as smooth and straightforward as possible. Our team is always available to answer questions, provide updates, and offer support at every stage of the project.

We believe that clear communication is key to a successful partnership, and we work hard to ensure that our clients are kept informed throughout the testing process. This includes providing detailed reports that clearly outline the results of our tests, as well as any recommendations for further action. Our goal is to give our clients the information they need to make informed decisions and to move forward with confidence.

Why Choose APT Sound Testing?

Choosing APT Sound Testing means choosing a partner that is committed to excellence in every aspect of our work. Our UKAS accreditation is a mark of the quality and reliability of our services, and we adhere to the strictest ISO standards in all of our testing and consultancy work. This ensures that our clients can have complete confidence in the results we provide and in the integrity of our testing processes.

Moreover, our extensive experience in the industry means that we have the knowledge and expertise to handle even the most challenging projects. Whether you’re developing a large residential complex, refurbishing an office building, or constructing a new school, we have the skills and resources to help you achieve your goals. Our team is passionate about what we do, and we are always looking for new ways to improve our services and deliver even greater value to our clients.

In summary, APT Sound Testing is your trusted partner for sound testing and acoustic consultancy services across London and the UK. Our comprehensive range of services, combined with our commitment to quality and customer satisfaction, makes us the ideal choice for any project requiring acoustic compliance. We invite you to contact us to discuss your next project and discover how we can assist you in achieving the required standards for sound and air tightness testing.

For more information or to schedule a consultation, please call us at 01525 303 905 or visit our website to contact us using our online form. We look forward to working with you on your next project and helping you achieve the acoustic performance you need for building completion.