Smoke Shaft Testing – Glossary of terms A to Z

Smoke shafts systems are incredibly important to fire safety in high rise buildings and are one of the most important elements of a smoke control system; therefore, the air tightness performance of the shaft is paramount. However, the the different terminology can be quite confusing for the average person.

To help provide clarity on some common air testing and smoke shaft terms, we’ve assembled this glossary of words that can be difficult to understand in the field of air testing smoke shafts. This includes terms related to air testing, smoke shafts, and test parameter information. Though it’s far from an exhaustive list, we hope it can provide some guidance.

Smoke Shaft Testing – A glossary of terms A to Z

Here’s an A-to-Z glossary of terms related to air testing for smoke shafts:

A – Airflow Rate: The volume of air moving through the smoke shaft per unit of time, typically measured in cubic meters per hour (m³/h). Most smoke shafts need to achieve an air tightness target of 3.8m3/hr/m2.

B – Building Regulations: Legal standards that govern the design, construction, and performance of buildings and smoke shafts, including fire safety measures.

C – Calibration: The process of verifying the accuracy of testing equipment against known standards. Smoke shaft air testing equipment should be UKAS calibrated.

D – Damper: A device installed within ductwork or smoke shafts to control airflow.

E – Extraction Rate: The rate at which smoke is removed from a space by ventilation systems.

F – Fan Pressurisation: Test: A diagnostic method used to determine the airtightness of a building by using a blower door fan to pressurise or depressurise the smoke shaft building.

G – Gauge Pressure: The pressure within a smoke shaft relative to the external atmospheric pressure, usually shown in Pascals (Pa).

H – Human toxicity: The impact on human health of toxic substances emitted to the environment, such as very leaky smoke shafts emitting smoke into the protected atmosphere.

I – Infiltration: The unintentional or accidental introduction of outside air into a smoke shaft, typically through air leakage paths such as cracks and openings within the envelope of the shaft.

J – Joint Sealing: The application of sealant at junctions, seams, or gaps to prevent air leakage in smoke shafts.

K – Kilopascal (kPa): A unit of pressure. 1 kPa equals 1,000 pascals (Pa).

L – Leakage Path: Routes through which air can enter or escape from a building or smoke shaft.

M – Mechanical Ventilation: The use of mechanical systems to control the indoor air quality by diluting and displacing indoor pollutants such as smoke or dust.

N – Negative Pressure: A condition where the air pressure inside the smoke shaft or building is lower than the air pressure outside. Some smoke shaft air tests are undertaken using negative pressure to find air leakage.

O – Opening (AOV) Doors: Doors that open up on each protected areas such as stairwell landing in the event of a fire.

P – Pressurisation Method: A technique used in air tightness testing where the building or smoke shaft is pressurised to a known level and the airflow required to maintain that pressure is measured. The readings are usually taken between 25 to 70 in 5Pa increments.

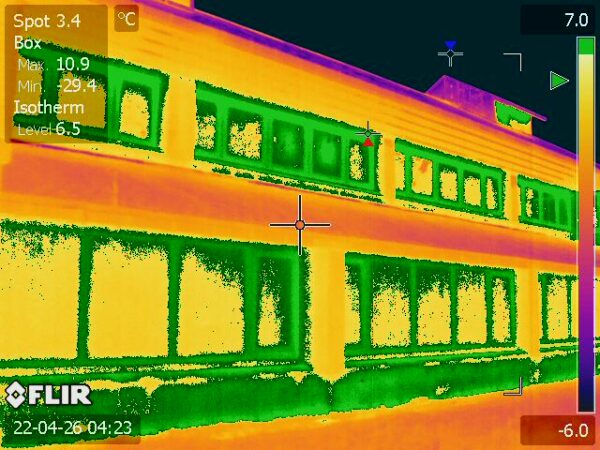

Q – Qualitative Analysis: The assessment of a building’s air tightness based on observations rather than numerical measurements, often using smoke or thermal imaging.

R – Retardant: A substance or device used to slow down or stop the spread of fire or smoke, such as fireboard and intumescent paint.

S – Smoke Shaft: A vertical duct designed to extract smoke from a building in the event of a fire.

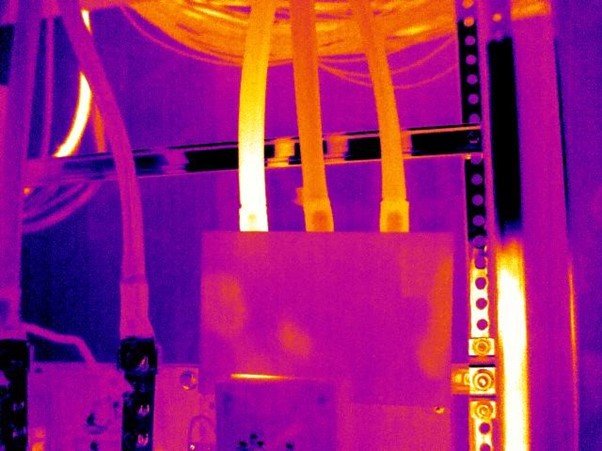

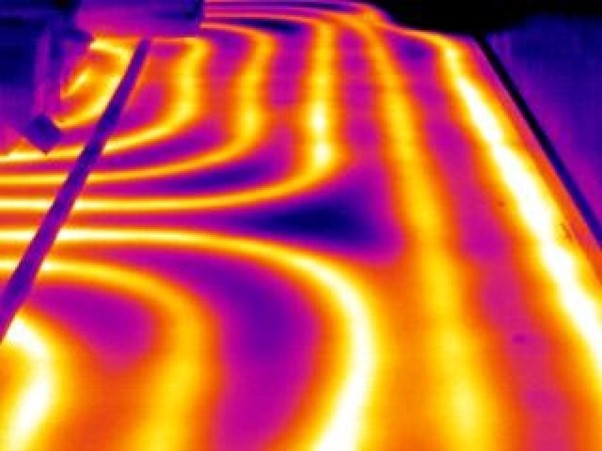

T – Thermal Imaging: The use of infrared cameras to detect temperature differences caused by air leakage. when used with a blower door its an extremely powerful tool to identify air leakage in smoke shafts.

U – Useful Space Heating: When the smoke shaft is heated to 6-8C higher than the surrounding building temperature, combined blower door and thermal imaging can be used to identify air leakage through the smoke shaft envelope.

W – Weather Sealing Strips: Materials used to seal gaps around doors to prevent air leakage.

X – Xenon Test: A method of detecting air leaks where xenon gas is used as a tracer in a pressurized space.

Y – Yield Point: The point at which a material or system begins to deform under stress, which could affect the air tightness of the smoke shaft.

Z – Zero Tolerance to Air Leakage: as the smoke shaft needs to attain a low air leakage figure to pass the air test, extra importance must be shown during the design and construction of the smoke shaft.

This glossary covers fundamental terms associated with air testing for smoke shafts. For more detailed information on the regulations surrounding smoke shafts, please don’t hesitate to contact APT Sound Testing to chat with our smoke shaft testing experts.