Improving your Air Test with Good Construction Detailing

Since April 2006, air testing has been required to be tested for Air Permeability, in order to comply with Part L1 & L2 of the Building Regulations. Since 2011 the air leakage target has reduced from 10m3/hr/m2 to 5m3/hr/m2. In the next 2 years it is expected that the target may be reduced to 3m3/hr/m2.

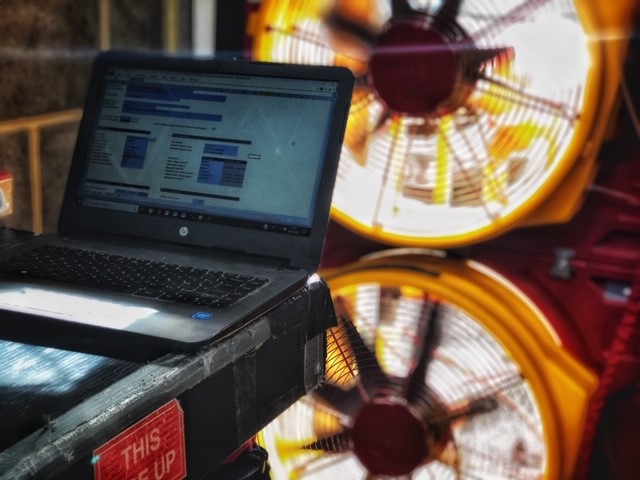

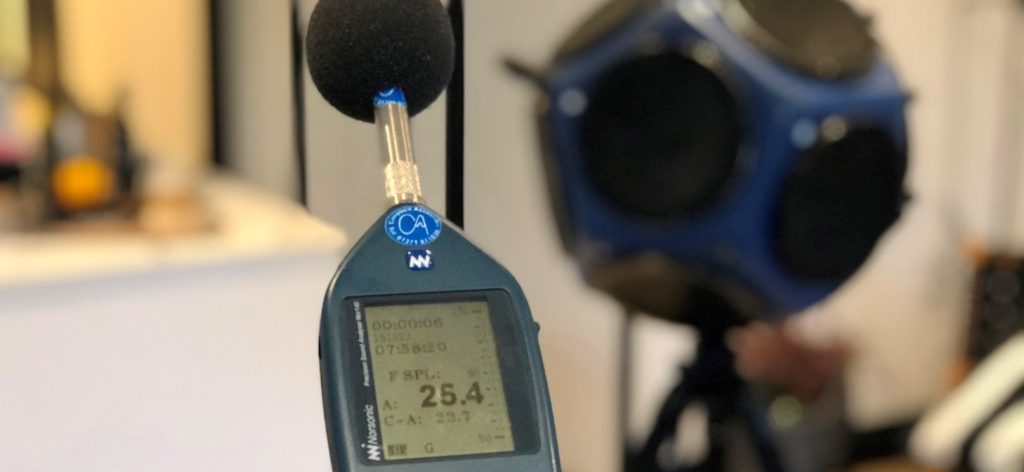

We provide a personal, helpful, efficient and cost effective air test service to our clients. Using the latest high power, portable door fans systems, we offer air testing to all building types, ranging from small rooms, flats & houses to office blocks & large distribution warehouses in accordance with the Building Regulations Part L1 & L2

Our air test fan systems are compact, discreet and fit simply into a personnel door. The system can easily be transported through areas of limited access or up to high level areas. Many contractors use us to undertake the testing in busy city centres or other tight access areas as we eliminate the site disruption caused by the larger trailer type air testing equipment.

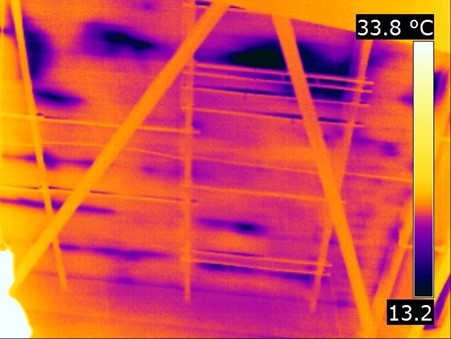

In the event of a building failing an air test we then offer smoke testing – both hand-puffer for dwellings and large scale smoke testing for commercial buildings. This highlights the areas of air leakage through the building fabric. We can then undertake a full written and photographic survey as reference for your site management and relevant subcontractors. We will also offer FREE advice on the best method to seal any leaking areas. The main benefits of this are:

• Air leakage paths are quickly identified in the event of a test failure

• A full written air leakage report is forwarded so remedial works can start straight away

• Building handover/practical completion and handover can be achieved more quickly

Construction Phase Consultancy

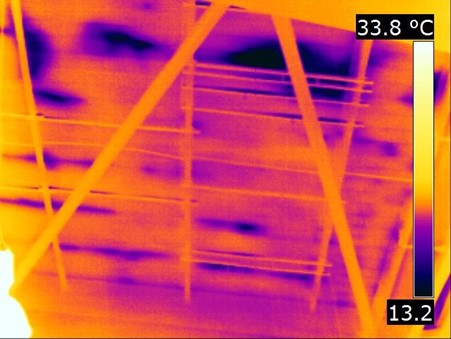

Air Pressure Testing has a practical ‘hands on’ approach during building construction and prefers to be involved as practically possible during this stage. We undertake periodic site visits to inspect the building envelope assembly as it is constructed and provide both written and photographic reports to enable any further works / remedial works deemed necessary to be accurately targeted. Site visits are generally to allow us to identify:

• Insulation placement, continuity and effectiveness at thermal bridge junctions

• Air barrier continuity within elements and at interfaces (particularly at sub-contract package interfaces)

Foundation/ground floor Initial works (Air Test risk factor 8)

a. Ensure that any penetrations through the air barrier (e.g. service pipes) have been dressed. Pre- formed collars, sometimes referred to as ‘top hats’, which seal to the membrane and around the throat of the pipes are effective means of achieving a good airtightness seal.

b. Ensure that the wall and floor damp-proof course/membrane forms an adequate airtight layer.

c. With using timber frame construction, check that the sole plate is sealed to the foundation/floor-slab.

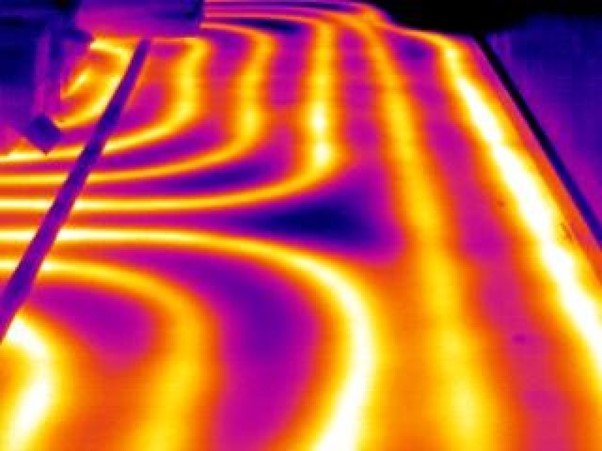

Internal Floors (Air Test risk factor 9)

a. Using joist hangers can limit penetrations through the air barrier.

b. If joists are to be supported by the wall, check that there is no air leakage into the cavity and the wall between the joists is fully filled/completed.

c. Ensure timber floor sheets/boards are well fitted and sealed at their edges as well as at junctions with perimeter walls with mastic.

d. Ensure the ceiling-to-wall joint has been sealed with mastic.

Eaves Level (Air Test risk factor 8)

a. Ensure the airtightness layer between the wall and ceiling/roof is continuous ceiling below the roof space.

b. Ensure there is a continuous air barrier over the whole ceiling area.

c. Ensure all service penetrations (ventilation ducts from extract fans and light fittings) have been properly sealed where they penetrate the air barrier as this is a major air leakage path.

d. Ensure all loft hatches are airtight and surrounds are sealed where they penetrate the air barrier.

External Doors & Windows (Air Test risk factor 7)

a. Ensure you always specify good quality windows and doors.

b. Always check that the wall-to-frame junction is properly sealed and continuous with mastic against the wall’s airtightness layer

c. Ensure all windows and doors have an appropriate weather-seal between the opening unit and the frame – check for missing weather seals.

d. All external doors should be fitted with draught excluders.

e. Ensure the letterbox is fitted with a draught excluder.

Envelope Service penetrations (Air Test risk factor 10)

a. Check for seals at service entry points (pipe and cable routes), e.g. around incoming water pipes, gas pipes, electrical cabling, as well as waste water pipes for sinks, baths, washing machines, dishwashers, etc. Seals should be provided internally and externally.

b. Where multiple services penetrate at the same point, there should be sufficient space to fully seal round each of them.

Brick/block masonry construction (Air Test risk factor 7)

a. Ensure the quality of construction as the work proceeds. Good mortar joints are required (i.e. no gaps around the blocks or bricks) on both internal and external faces – this also reduces sound transmission.

b. Ensure all block-work is paint grade and painted were possible.

c. The application of wet plastering, parging or the addition of fully-sealed dry lining will create a good air seal.

d. Parging is an effective method of sealing around joists that penetrate the inner leaf of an external wall.

e. Check that there is a good seal around all services that penetrate the masonry.

Plasterboard Dry lining (Air Test risk factor 10)

a. Check the plasterboard is continuous (e.g. there are no large holes behind the kitchen units/bath).

b. Ensure that airtightness measures have been incorporated at all edges, particularly at the floor/ceiling junctions and around openings.

c. Check the plasterboard is correctly detailed at joints, corners, reveals and window sills. Plasterboard should be mounted on ribbons of plaster or adhesive around all the edges (rather than dabs) to prevent air leaking through the porous block-work behind.

Sealed Membranes & Vapour barriers (Air Test risk factor 9)

a. Where the vapour barriers have been used as the air tight barrier, check that it is complete, that all joints have been sealed and it’s not damaged.

Timber frame construction (Air Test risk factor 8)

a. It’s usually easier to make timber frame dwelling airtight than other forms of construction. This is partly due to pre-fabricated construction and the use of the impermeable vapour barrier as the air barrier. The plasterboard layer can also become an air tight layer.

b. Where vapour barriers have been used special care will be needed to avoid it being torn. Any damage to the vapour barrier must be carefully repaired.

Remedial Air Sealing Solution

1. Smoke Investigation with Air Testing Fans:

APT’s Air Sealing Team utilise smoke investigation to identify the air leakage paths and prioritise which can be sealed first to attain an air test pass.

2. Remedial Air Sealing Works:

APT can carry out the air sealing works. Typically allow for a 2-4 man Remedial Air Sealing Team. Adequate access must be provided for all sealing works. We provide all air sealing Materials – Rates provided on Request.

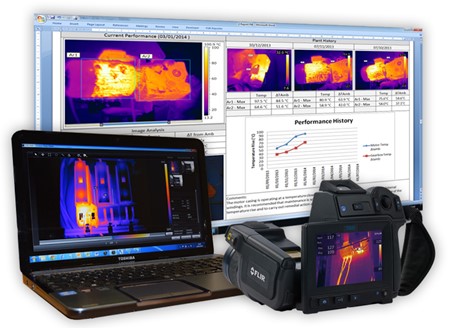

3. On-going Air Tightness Assessments:

Enables the APT Sealing Team to seal the building until the fans indicate that the air

test would pass – thereby minimising the remedial works and time on site.

4. Final Air Test:

APT’s Air Test Technician carries out a final independent test for compliance.

Whether you need a full on-going air tightness design/consultancy service, or just a simple air test, Air Pressure Testing have the knowledge and experience to ensure your building passes first time.

If you are unsure of the air tightness services you require, please visit our website, or call us on 01525 303905 and one of our Air Tightness Consultants will guide you through the process, ensuring that you receive the right level of advice at the right time.